Nonwoven fabric composite antibacterial agent and preparation method thereof

A composite antibacterial agent and non-woven fabric technology, which is applied in textiles and papermaking, fiber treatment, biochemical fiber treatment, etc., can solve the problems of easy discoloration of antibacterial non-woven fabrics, difficulty in applying light-colored non-woven fabrics, and limited bactericidal ability , to achieve the effect of improving the bactericidal strength and bactericidal spectrum breadth, increasing the washing fastness and good absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

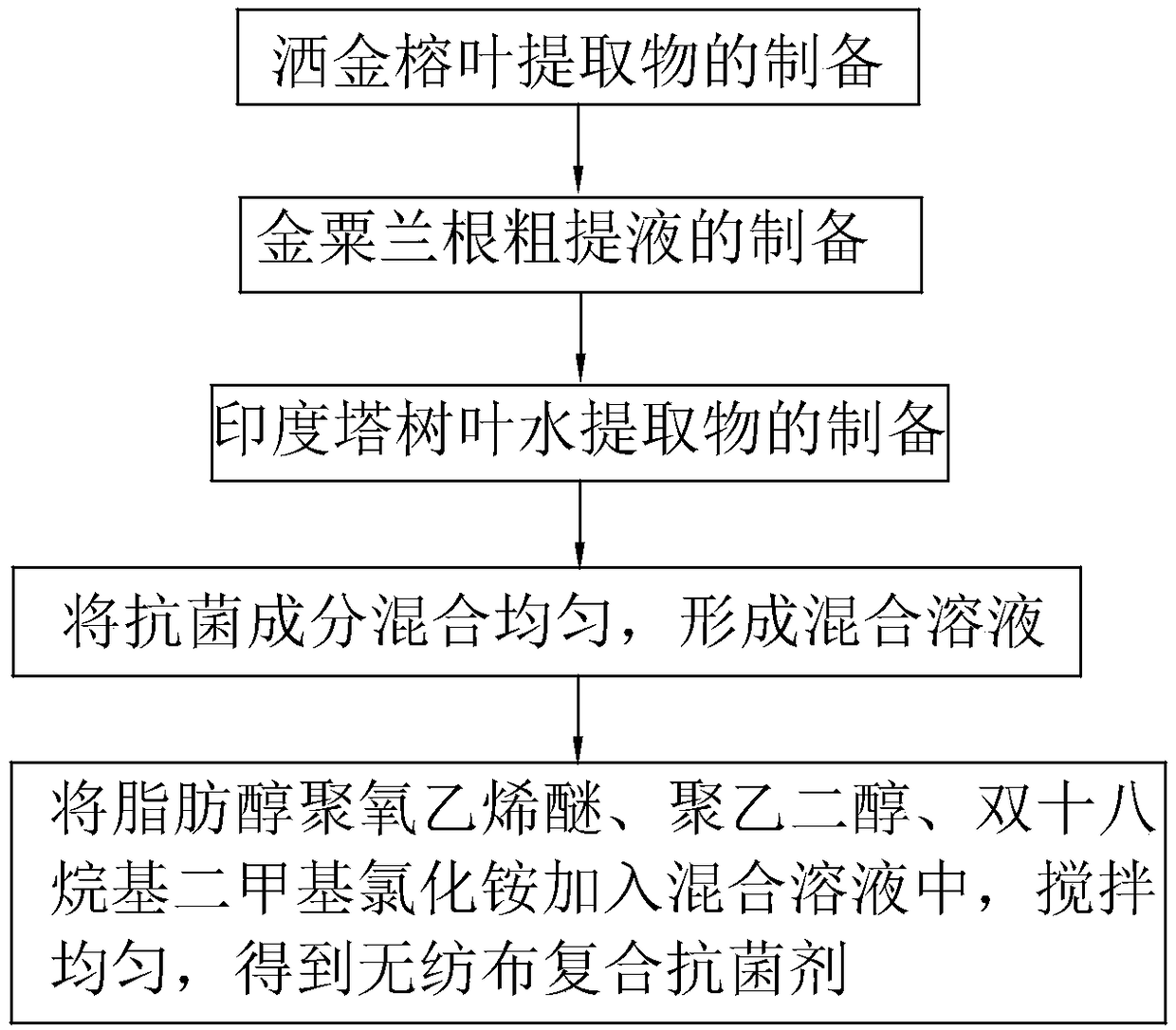

Method used

Image

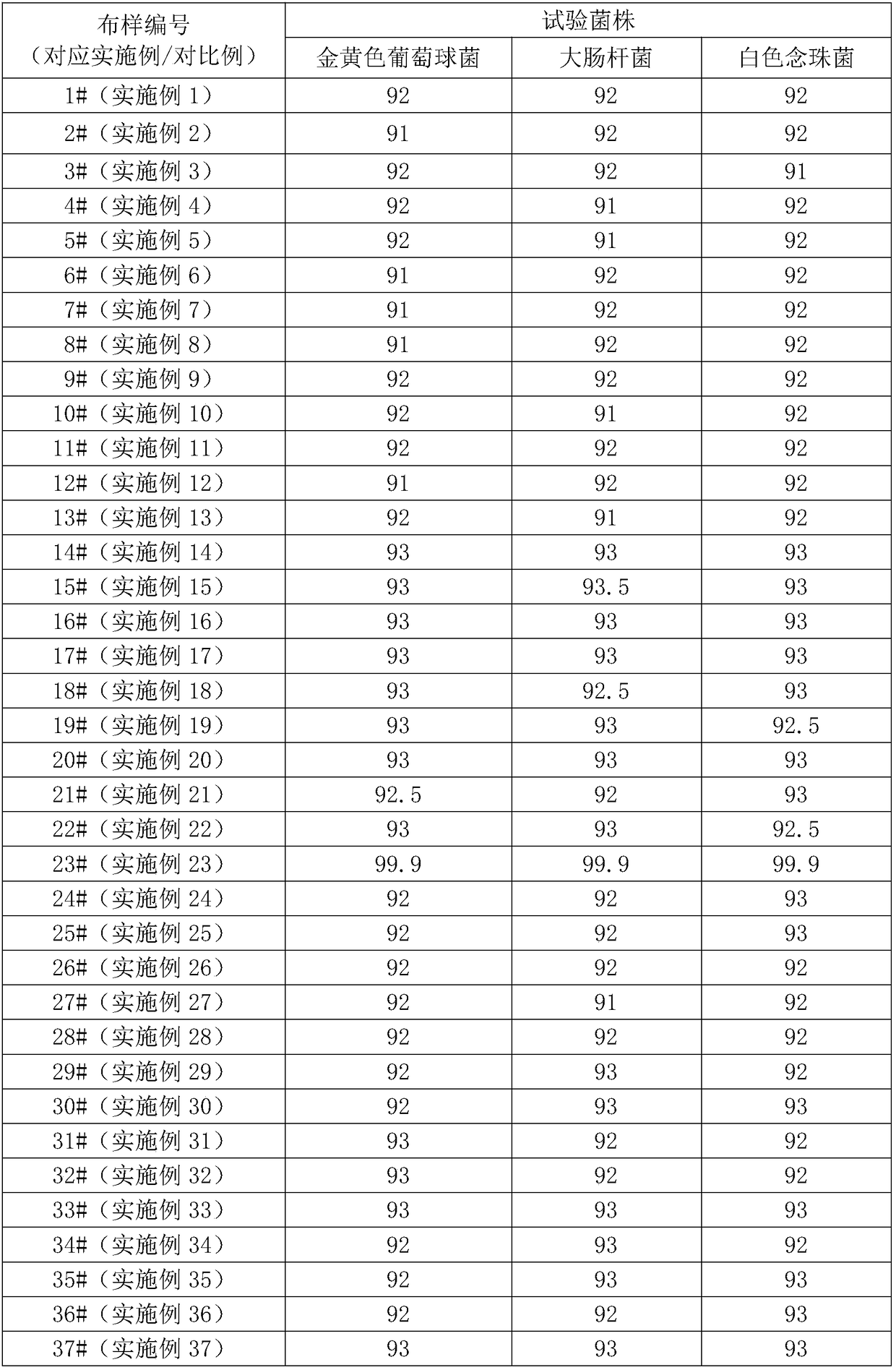

Examples

Embodiment 1

[0053] Embodiment 1: A kind of non-woven composite antibacterial agent, each component and its corresponding weight percentage are as shown in Table 1, and prepare and obtain through the following steps:

[0054] Step 4, dissolving the polyhexamethylene guanidine salt antibacterial agent and the cationic quaternary ammonium salt antibacterial agent in pure water, stirring evenly, and stirring evenly under a closed condition of 45-55°C to form a mixed solution;

[0055] Step five, after the mixed solution obtained in step four was left to stand for 10 minutes, fatty alcohol polyoxyethylene ether, polyethylene glycol, dioctadecyldimethylammonium chloride were added to the mixed solution, and the Stir in the temperature range of ℃ for 5 minutes until the mixture is evenly stirred, and keep it still for more than 10 minutes under airtight conditions, then take the supernatant to obtain a non-woven fabric composite antibacterial agent.

[0056] The antibacterial agent of polyhexame...

Embodiment 2~5

[0057] Embodiments 2 to 5: A non-woven composite antibacterial agent. The difference from Embodiment 1 is that each component and its corresponding weight percentage are shown in Table 1.

[0058] Each component and weight percentage thereof in table 1 embodiment 1~5

[0059]

Embodiment 6

[0060] Embodiment 6: A non-woven composite antibacterial agent, the difference from Example 1 is that polyhexamethylene guanidine hydrochloride is replaced by polyhexamethylene biguanide hydrochloride in equal parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com