Water cooling device applied to spinning heat roller

A water-cooling device and spinning technology, applied in household refrigeration devices, applications, household appliances, etc., can solve the problems of water pipe corrosion, shutdown, production cost increase, etc., and achieve the effect of reliable guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

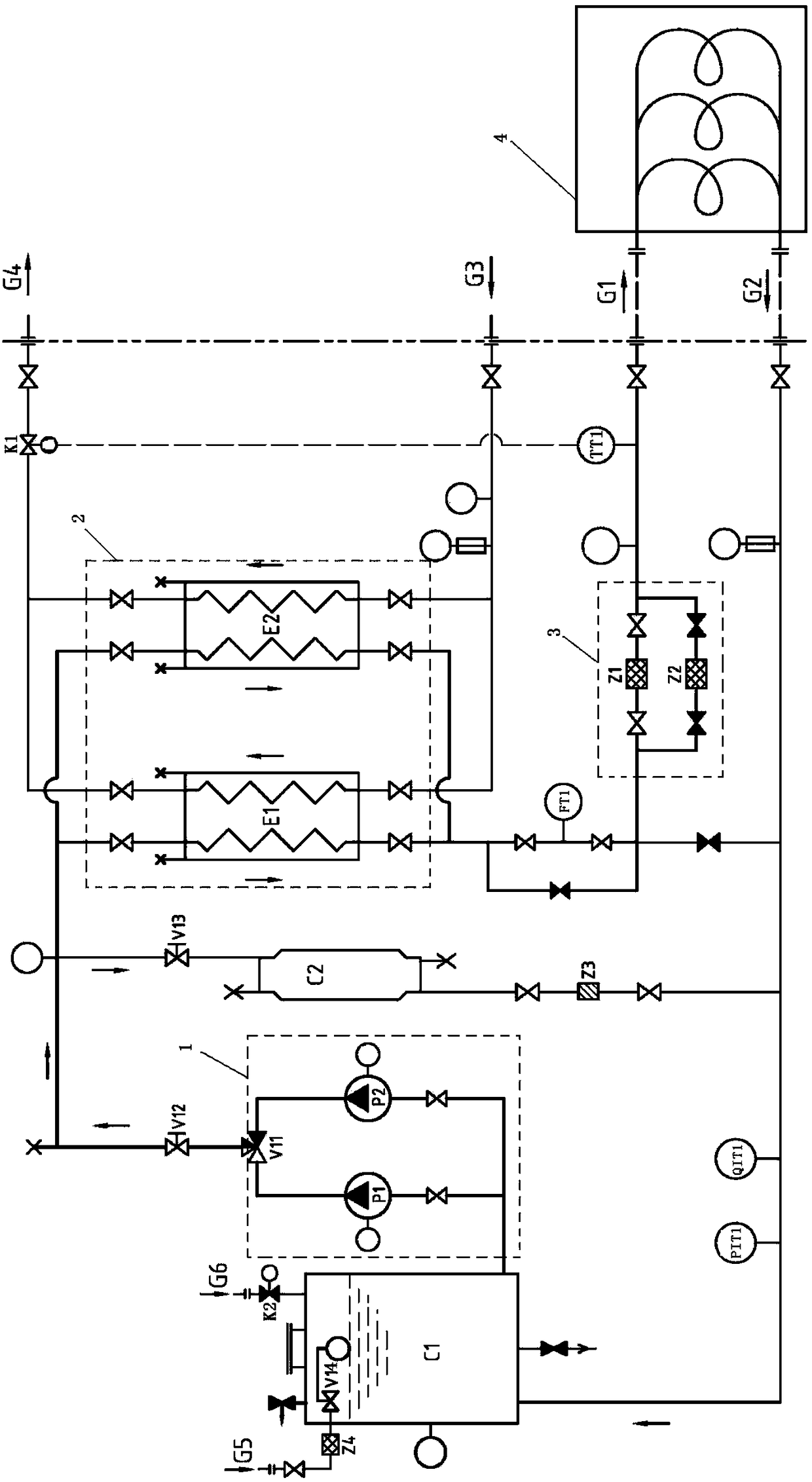

[0015] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

[0016] see figure 1 , a kind of water-cooling device that is applied to spinning heat roller of the present invention, comprises power pump group 1, heat exchanger group 2, softening water device C2, water storage tank C1, filtering device 3 and monitoring device;

[0017] The power pump group 1 includes a soft water pump P1, a soft water pump P2 and an automatic reversing valve V11, and the soft water pump P1 and the soft water pump P2 are connected to both sides of the automatic reversing valve V11. The soft water pump P1 and the soft water pump P2 maintain the circulation of the cooling liquid between the water cooling device and the spinning hot roller, and they are the standby working conditions for each other. The automatic switching valve V11 completes the regular automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com