Microfluidic chip based on Morpho menelaus and manufacturing method thereof

A technology of microfluidic chips and manufacturing methods, applied in chemical instruments and methods, laboratory containers, measuring devices, etc., can solve problems such as large surface roughness, incompatibility, and limited microchannel resolution, and achieve Extensive sources of raw materials, rapid response, and the effect of promoting application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

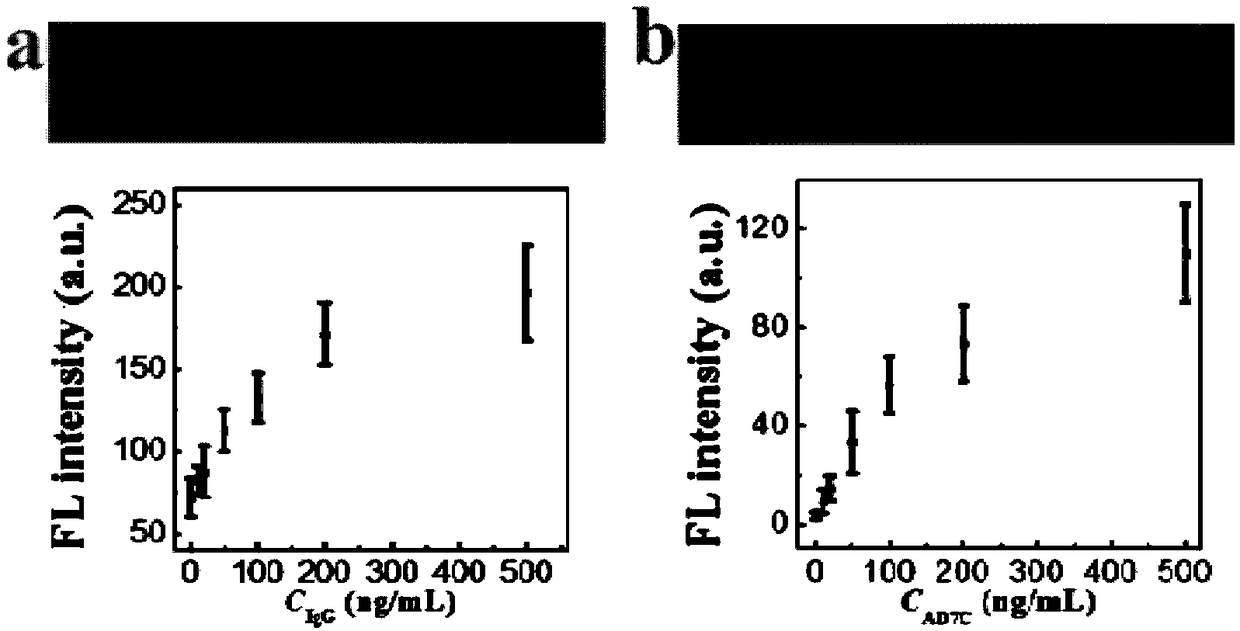

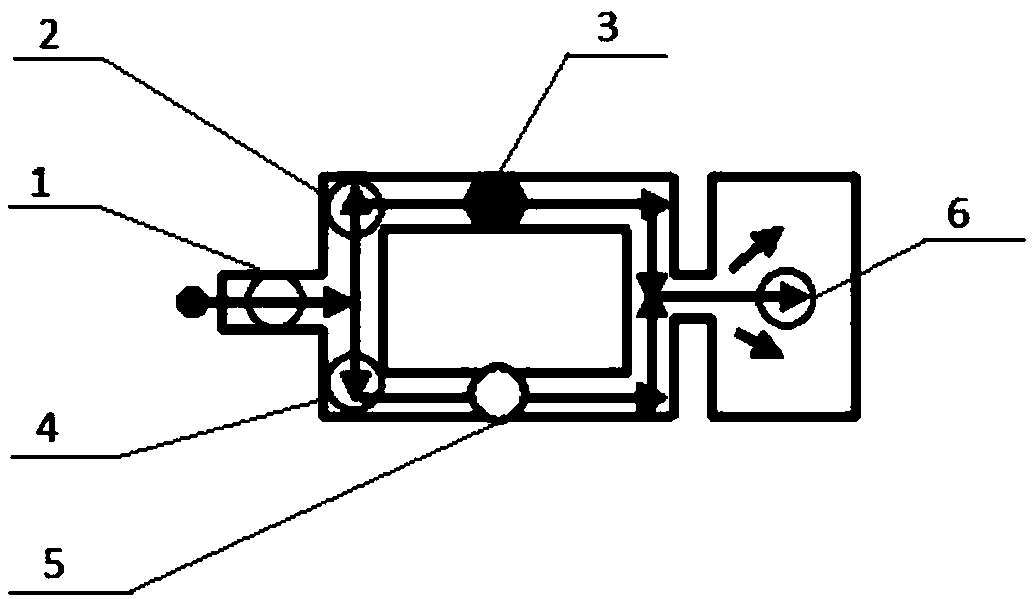

[0035] 1. Microfluidic chip based on Morphobis:

[0036] Such as figure 1 As shown, the microfluidic chip based on Morpholipris provided by the present invention includes a test sample loading area 1, a fluorescently labeled antibody loading area, a capture antibody loading area, and a waste liquid area 6 that are connected in sequence, in which a fluorescent label is connected. The channel of the antibody loading area and the capture antibody loading area is two parallel channels, and the first fluorescently labeled antibody loading area 2 and the second fluorescently labeled antibody loading area 4 are arranged symmetrically on the passage, and the first capture antibody loading area 3 and the second capture antibody loading zone 5.

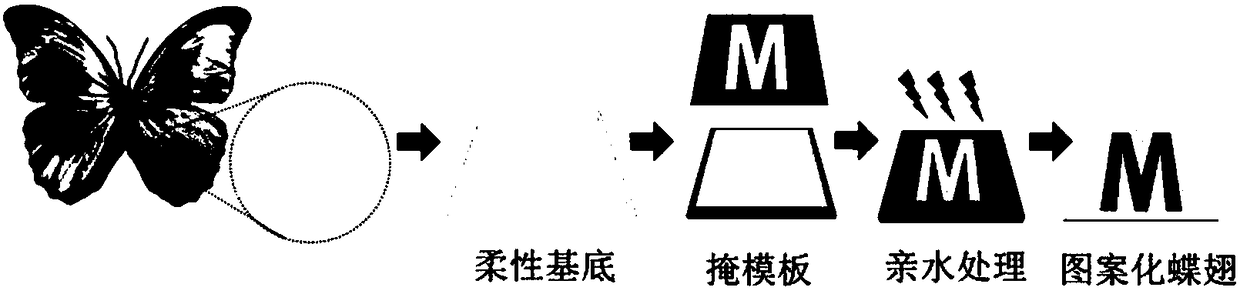

[0037] 2. The fabrication method of the microfluidic chip based on Morpholipae:

[0038] Such as figure 2 As shown, M in the figure represents a microfluidic chip (Microfluidic chip).

[0039] First, take a small piece of hindwing of Morph...

Embodiment 2

[0043] Same as Example 1, the difference is that the channel connecting the fluorescently labeled antibody loading area and the capture antibody loading area is a single channel, the manufacturing method is the same as that of Example 1, and the final detection effect is the same as that of Example 1.

Embodiment 3

[0045] Same as Example 1, the difference is that the channels connecting the fluorescently labeled antibody loading area and the capture antibody loading area are three parallel channels, the manufacturing method is the same as Example 1, and the final detection effect is the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com