Micro-structure mode-locking device employing tapered optical fiber evanescent field and manufacturing technique therefor

A tapered optical fiber and evanescent field technology, applied in optical components, optics, instruments, etc., can solve the problem of small effective contact area between saturable absorbing material and tapered optical fiber cone waist, poor control and repeatable production performance, and inconvenience to the industry issues such as low cost, low insertion loss, and high damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the drawings in the embodiments of the present invention. The described embodiments are only some of the embodiments of the invention.

[0029] The technical scheme that the present invention solves the problems of the technologies described above is:

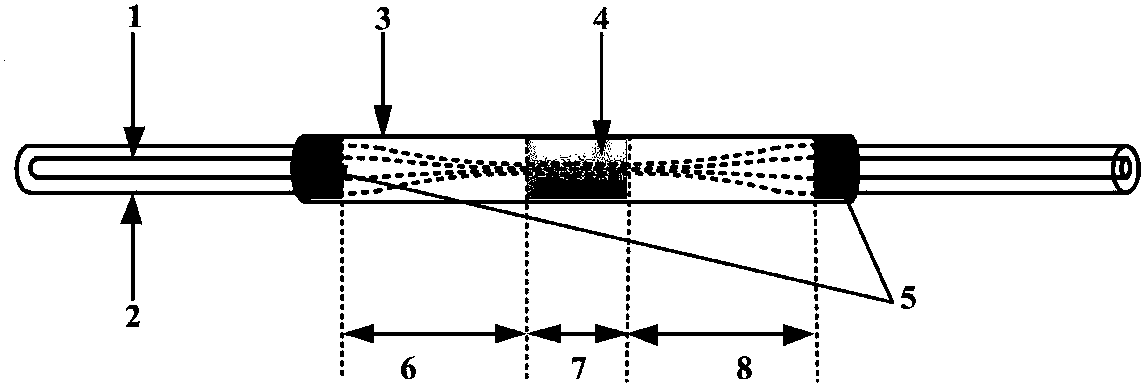

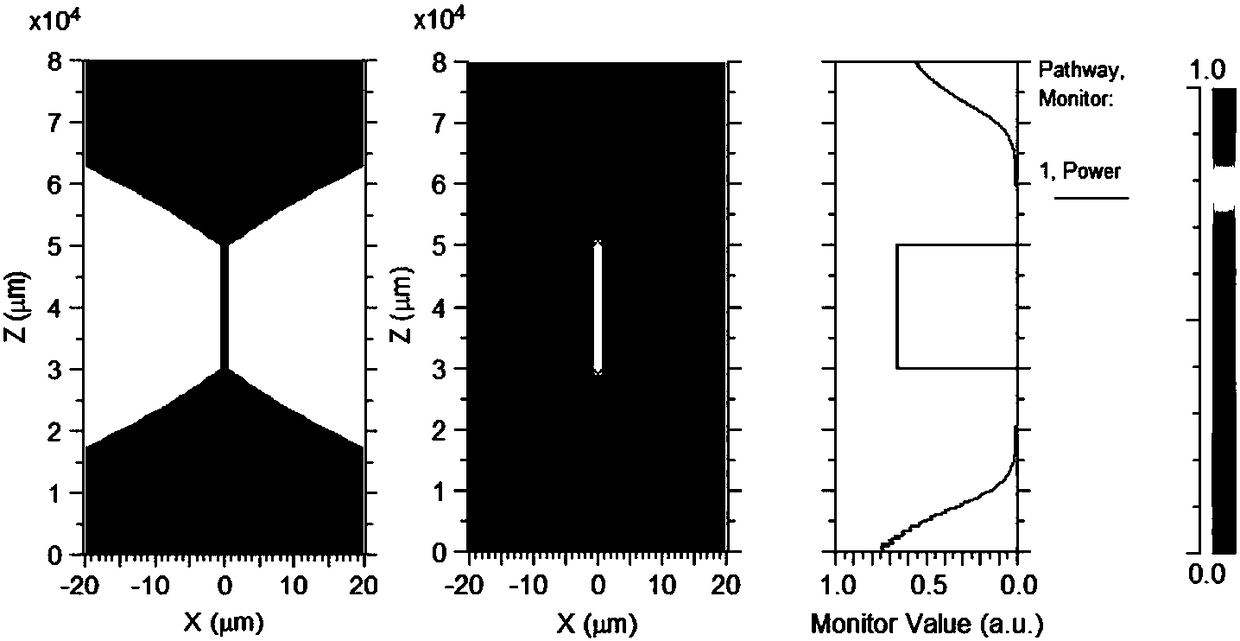

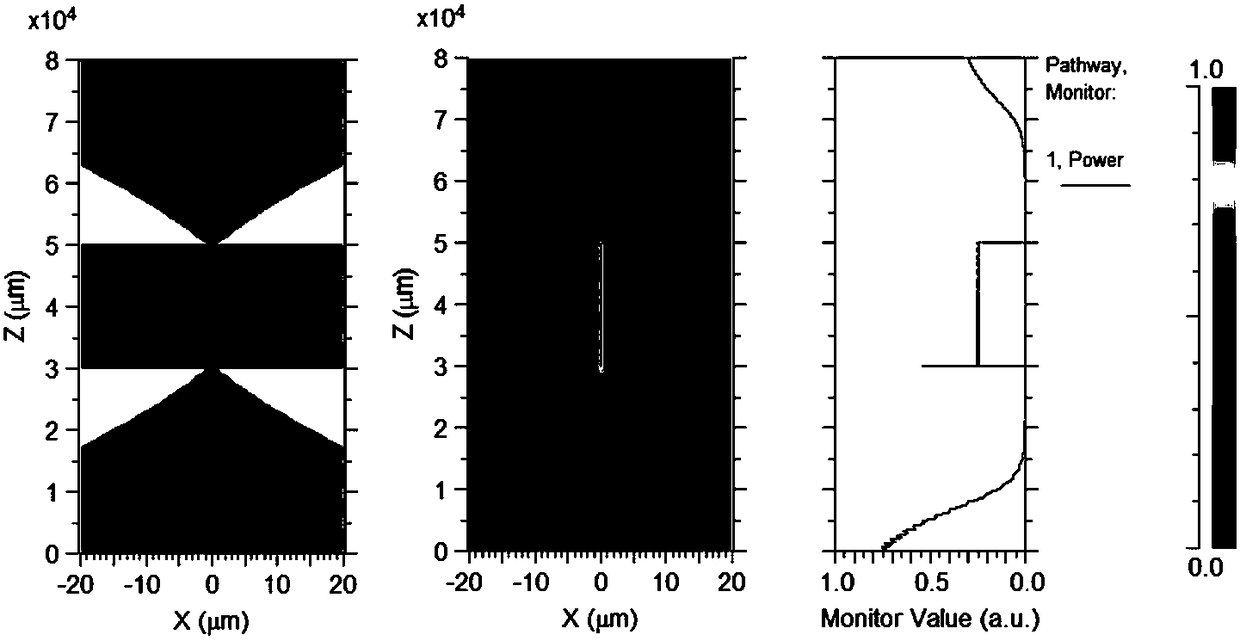

[0030] A microstructured mode-locked device that utilizes the evanescent field of a tapered optical fiber to saturably absorb nanomaterials adopts such as figure 1 The structure shown is a microstructure area mainly composed of ordinary single-mode optical fiber, capillary glass tube, refractive index matching liquid-saturated absorbing material mixed liquid and ultraviolet glue.

[0031] The object of the present invention is to solve the problems existing in the above-mentioned combination of tapered optical fiber and saturable absorbing material, and proposes a method consisting of ordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com