Electromagnetic valve for hydraulic media

A hydraulic medium and solenoid valve technology, applied in the field of solenoid valves, can solve problems such as wear and tear, and achieve the effects of improved sliding characteristics and life, and low eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

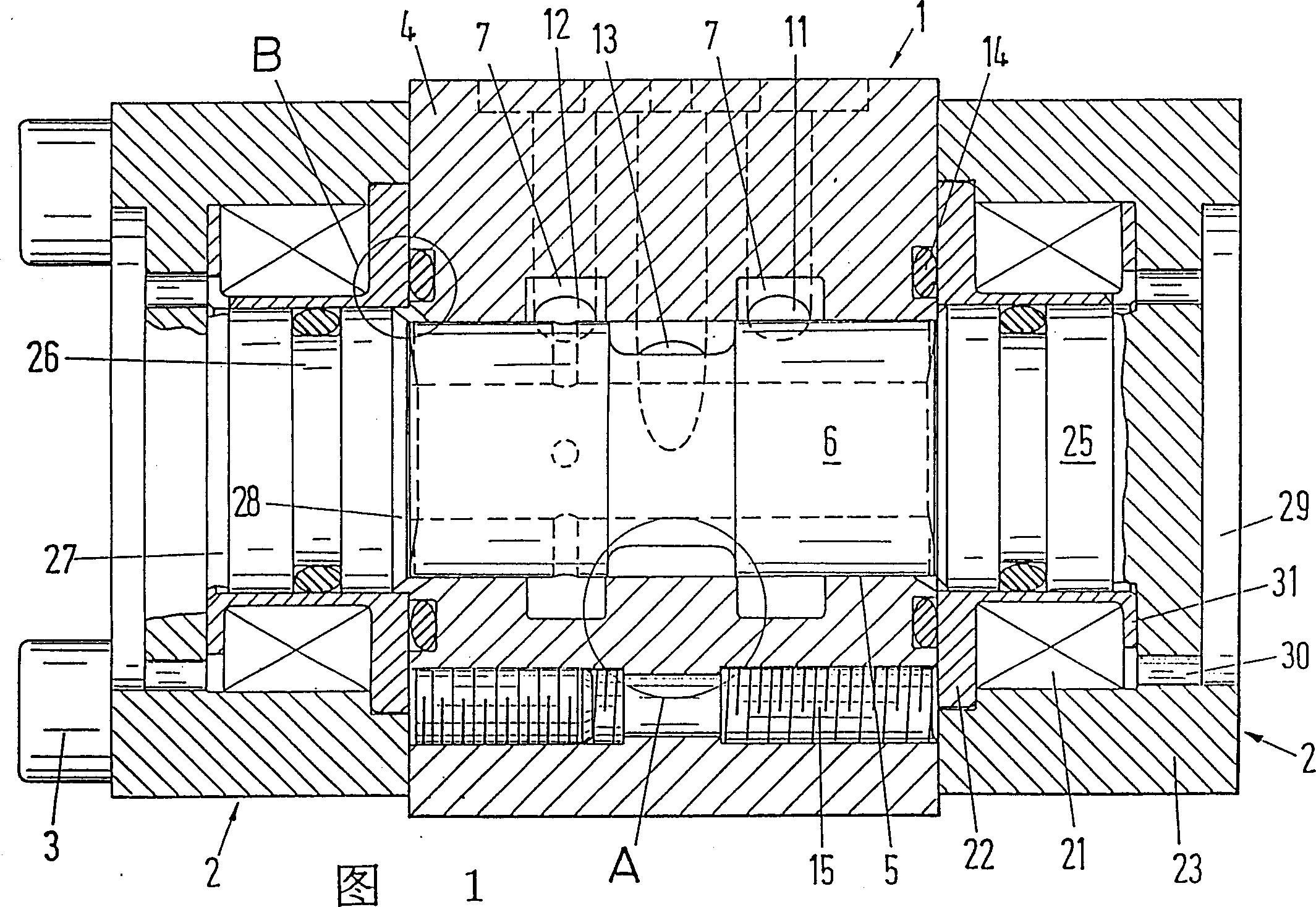

[0012] The valve essentially comprises a valve part 1 and two drive parts 2 which are formed as electromagnets and mounted on the valve part 1 by means of screws 3 .

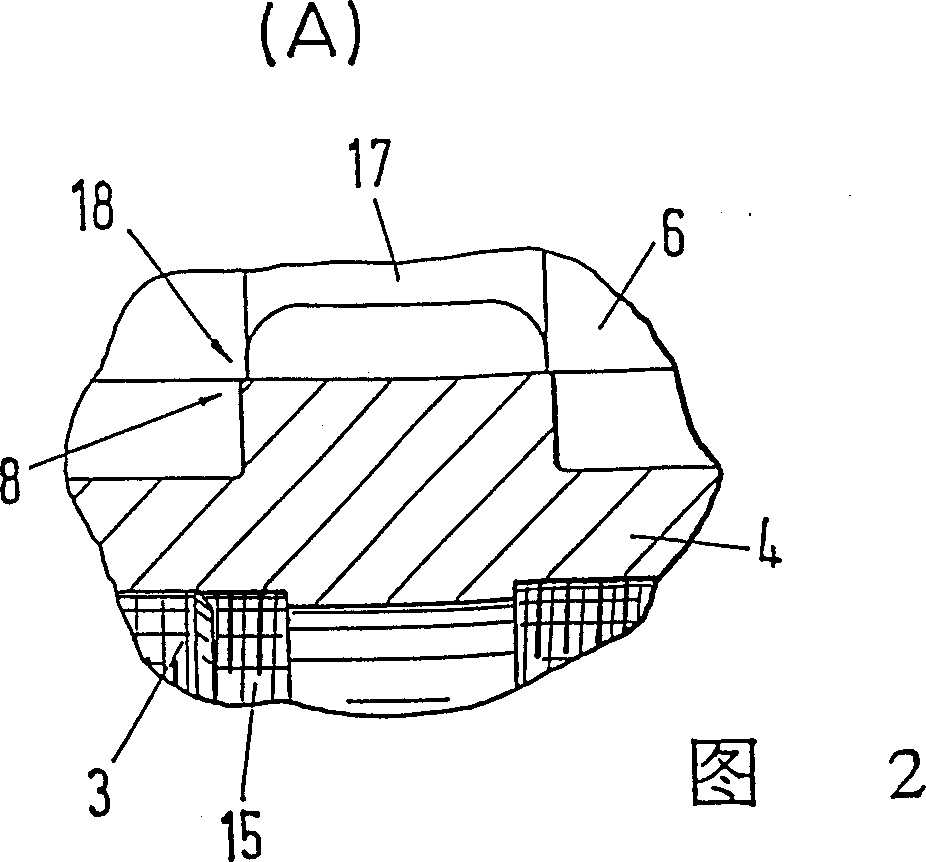

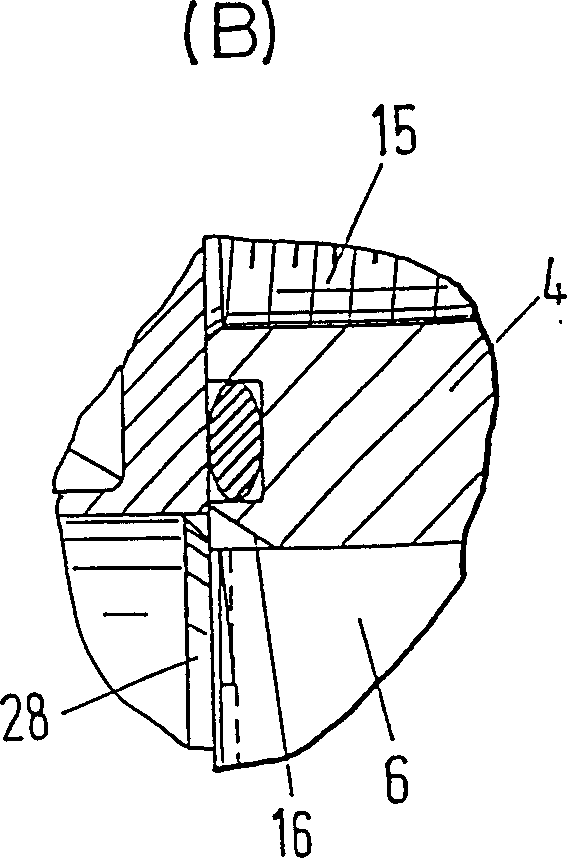

[0013] The valve part 1 comprises a housing 4 with a through opening 5 along the cylinder axis and a slide valve or valve plug 6 arranged to be movable back and forth in the through opening. The housing 4 is composed of magnetic material. It can be seen from FIG. 1 that the length of the valve housing 4 is less than 2.5 times the outer diameter of the slide valve 6 . Two annular grooves 7 are formed in the housing 4 and are formed to run parallel in the through-hole 5 in such a way that each of the adjacently located edges forms a control edge 8 ( FIG. 2 ). In addition, a supply passage 11 and a return passage 12 each leading to the ring groove 7 and a user passage 13 leading to the through hole 5 are formed in the housing. An annular cutout is provided on the end face of the housing for receiving the sealing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap