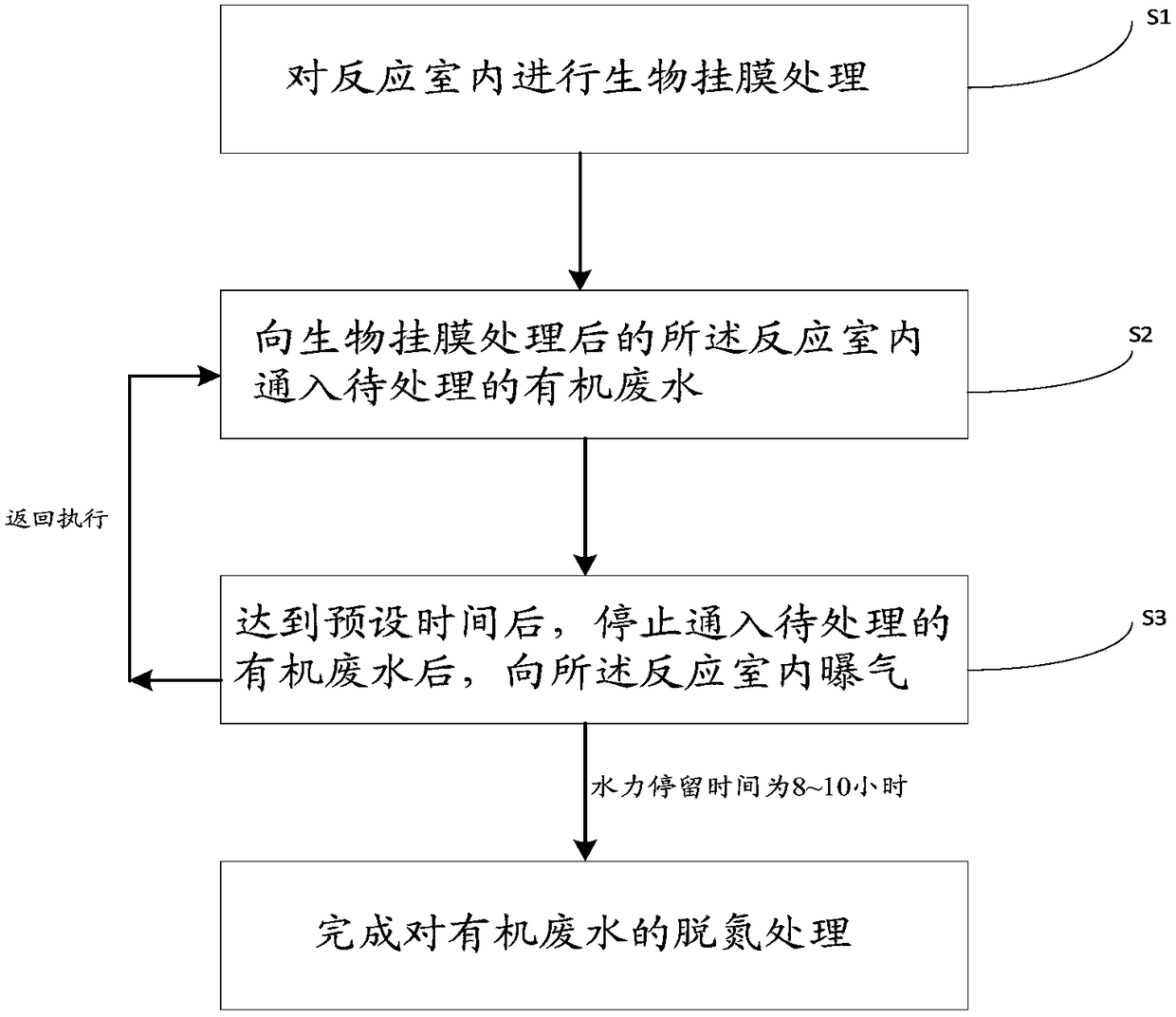

Denitrification treatment method for organic wastewater

A technology of organic wastewater and treatment methods, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as low total nitrogen removal efficiency, and reduce equipment footprint. , the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

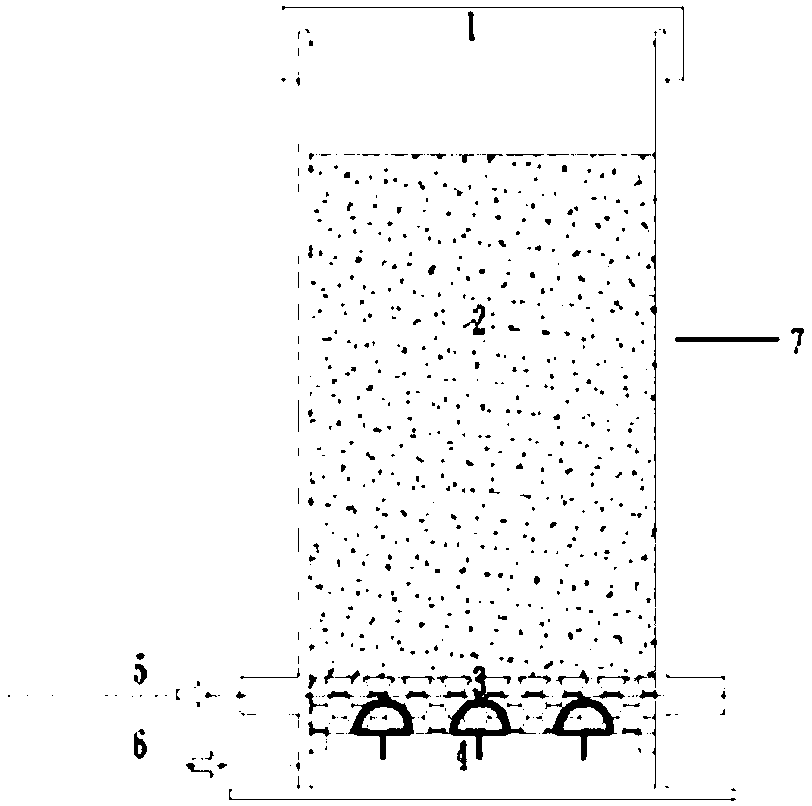

[0083] Integrated denitrification reactor such as figure 2 As shown, it includes an outlet weir 1, a ceramsite layer 2, a cobblestone layer 3, a water distributor 4, an intermittent air inlet pipeline 5, an intermittent water inlet pipeline 6, and a reaction chamber 7.

[0084] The reaction chamber 7 is made of plexiglass, cylindrical in appearance, with a height of 1.25m and a diameter of 0.1m. There is 5L ceramsite filter material inside. The ceramsite diameter is 3-5mm and the density is 1.75g / cm 3 , with a specific surface area of about 4m 2 / g.

[0085] (1) Biofilm treatment stage:

[0086] Soak the ceramsite in the reaction chamber with a starch aqueous solution with a COD value of 300mg / L, and continuously feed air into the reaction chamber, and the intake rate of the air is 30L / min;

[0087] After 24 hours, the COD value of the aqueous sugar solution soaked in ceramsite was determined to be 250mg / L;

[0088] Remove the aqueous carbohydrate solution in the reacti...

Embodiment 2

[0105] (1) biofilm processing stage, same as embodiment 1;

[0106] (2) Denitrification stage:

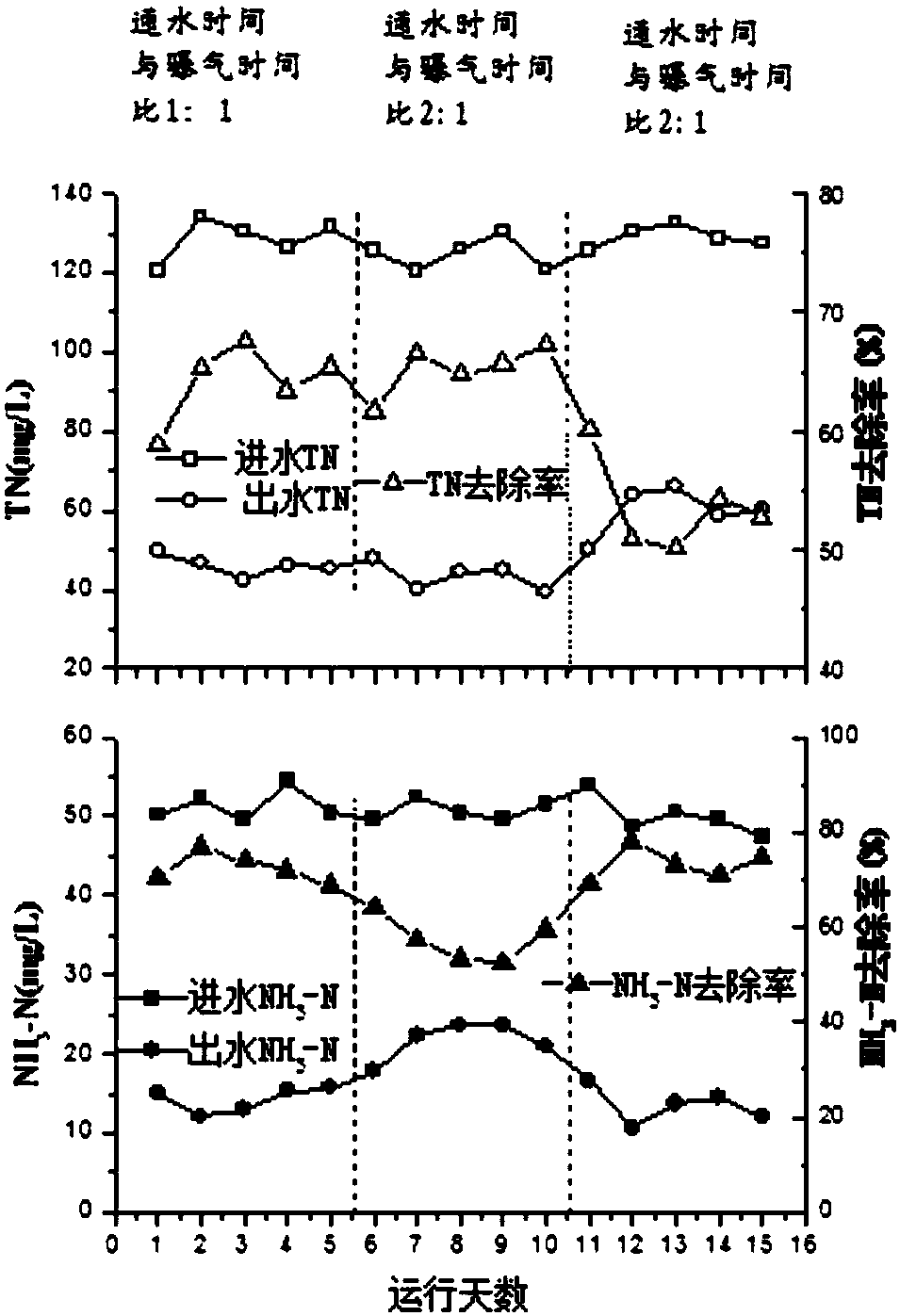

[0107] The organic waste water produced in the production process of the thin film transistor liquid crystal display with a carbon-to-nitrogen ratio of 4:1 is passed into the reaction chamber after the biofilm treatment, and after 0.5 hours,

[0108] After stopping the introduction of the organic waste water to be treated, aerate the reaction chamber;

[0109] After aeration for 0.5 hours, stop the aeration and continue to feed the organic wastewater;

[0110] The process of feeding organic wastewater and aeration is carried out alternately; the process of feeding organic wastewater and aeration is performed once, and the air-water ratio is 4:1.

[0111] Maintain the hydraulic retention time of the organic wastewater to be treated at 8 hours, and run for 4 to 7 days.

[0112] The organic waste water produced in the production process of the thin-film transistor liquid crystal di...

Embodiment 3

[0129] (1) biofilm processing stage, same as embodiment 1;

[0130] (2) Denitrification stage:

[0131] The organic waste water produced in the production process of the thin-film transistor liquid crystal display with a carbon-to-nitrogen ratio of 4:1 is passed into the reaction chamber after the biofilm treatment, and after 1 hour,

[0132] After stopping the introduction of the organic waste water to be treated, aerate the reaction chamber;

[0133] After 1 hour of aeration, stop the aeration and continue to introduce organic wastewater;

[0134] The process of feeding organic wastewater and aeration is carried out alternately; the process of feeding organic wastewater and aeration is performed once, and the air-water ratio is 4:1.

[0135] The hydraulic retention time (HRT) of the organic wastewater to be treated is maintained at 8 hours, and the operation days are 5 days.

[0136] The organic waste water produced in the production process of the thin-film transistor li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com