Electronic product production process

A production process and technology for electronic products, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of high friction on the surface of the protective film, easy scratching of the protective film, and exposure of IC patterns. Good effect, good grinding effect, and the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

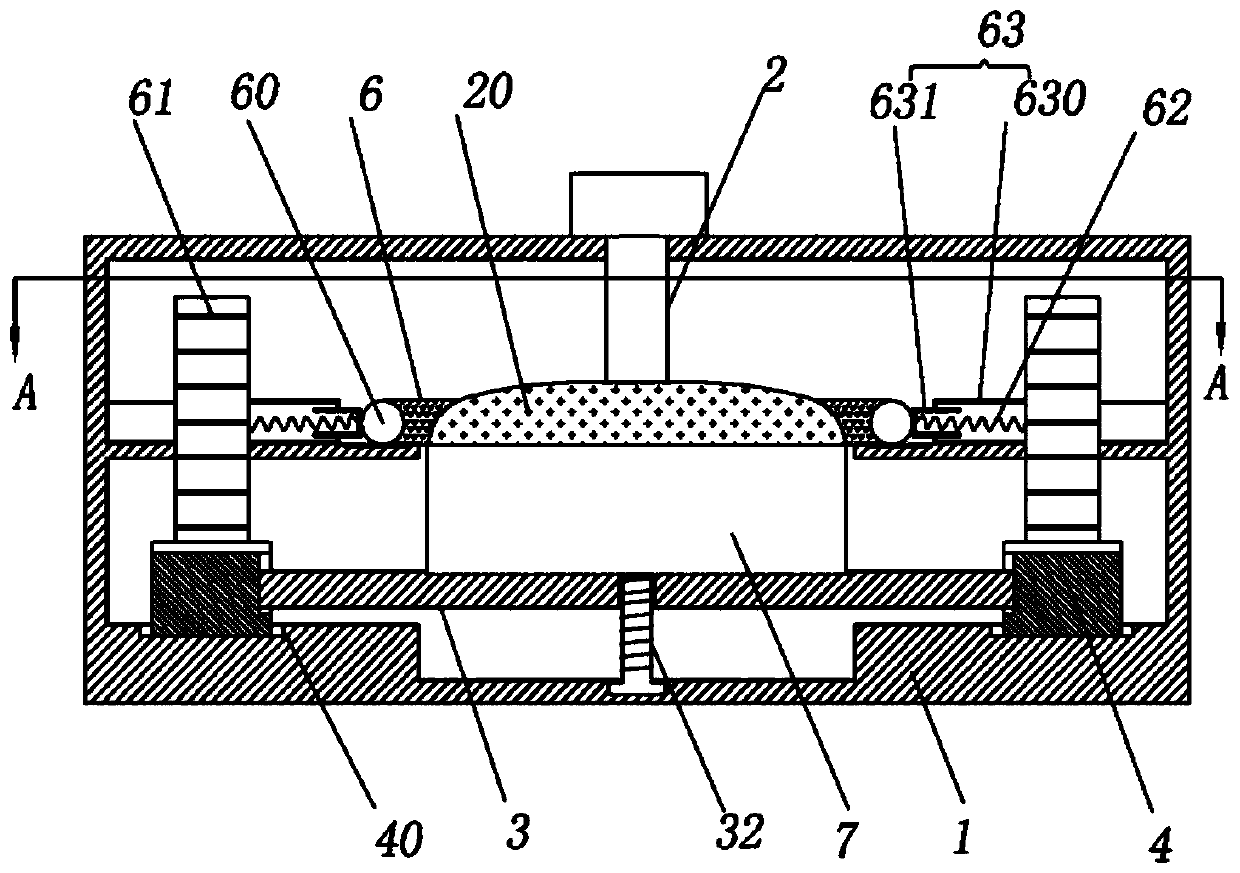

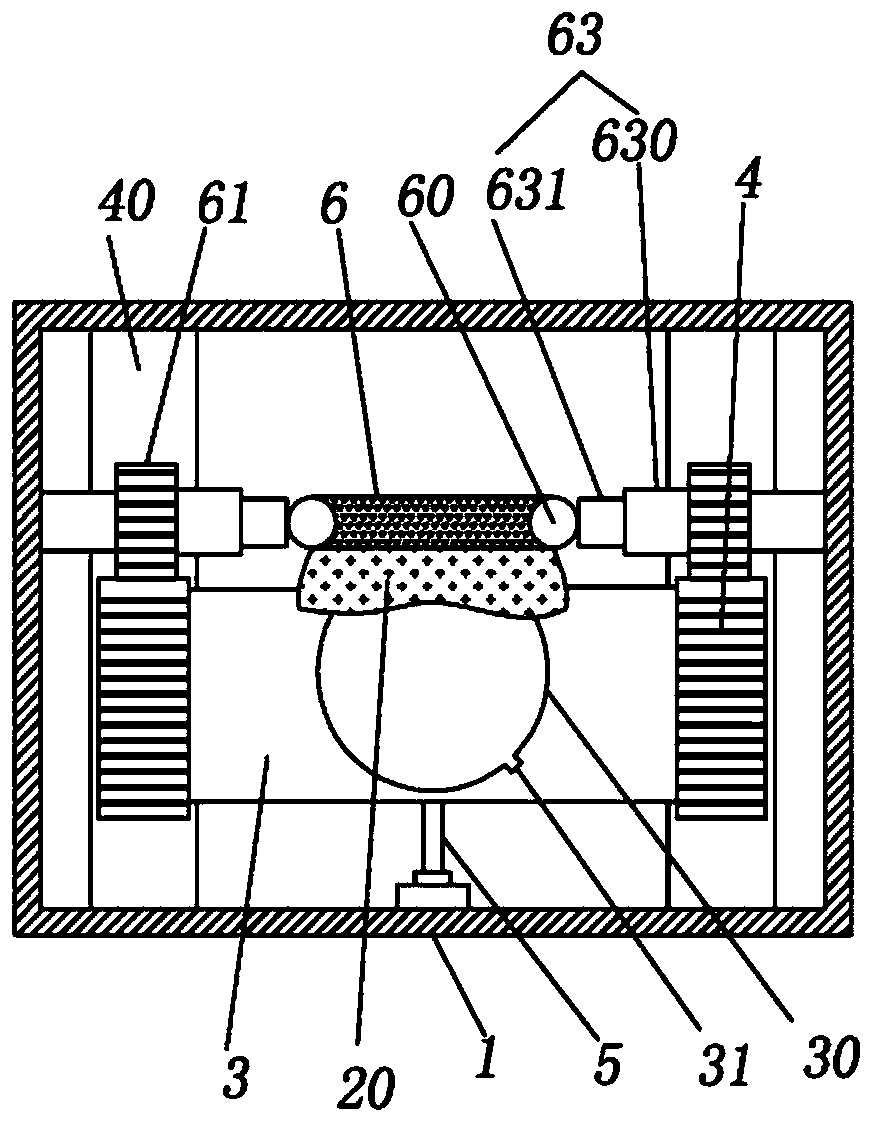

[0030] The embodiment is basically as attached figure 1 Shown:

[0031] The electronic product production process includes the following steps:

[0032] 1) Wafer preparation: Clean the wafer surface with a cleaning solution, the cleaning solution includes ammonia water and hydrogen peroxide, and NH 3 :H 2 o 2 :H 2 The mass ratio of O is 1:1-2:150-200; then dry the wafer with cold air.

[0033] 2) Mounter preparation: The mounter includes a frame 1, a mount mechanism 2, a moving mechanism and a flattening mechanism. Wherein, the placement mechanism 2 may adopt a structure in the prior art, that is, a structure capable of pulling the protective film 20 to the surface of the wafer 7 and performing subsequent cutting. like figure 2 As shown, the moving mechanism includes a support plate 3, a sliding rack 4, and a mover for translation of the support plate 3. The mover in this embodiment is a moving pneumatic cylinder 5. Of course, a hydraulic cylinder can also be used to r...

Embodiment 2

[0045] The difference between the present invention and Example 1 is that the cleaning solution in step 1) includes ammonia and hydrogen peroxide, and the NH 3 :H 2 o 2 :H 2 The mass ratio of O is 1:2:200; in step 8), the wafer is ground to a thickness of 350um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com