Cultivation device for promoting plant growth

A technology for promoting plant growth and cultivation devices, applied in the field of soilless cultivation, which can solve the problems of restricting the promotion and application of soilless cultivation technology, increasing cultivation costs, and high cultivation costs, and achieve the effects of reducing energy consumption, saving energy and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

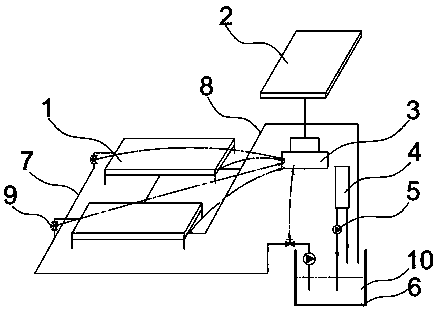

[0020] Such as Figure 1-4 Shown, the cultivation device that promotes plant growth comprises:

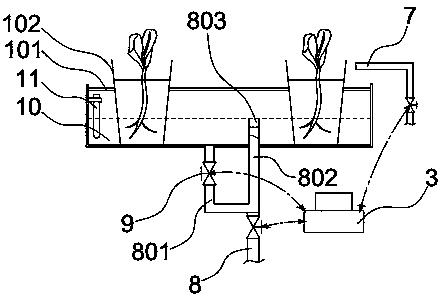

[0021] For placing the cultivation tank 1 of the cultivation pot 102, the upper and lower ends of the cultivation tank 1 pass the liquid inlet pipe 7, the liquid outlet pipe 8 and the liquid tank 6 to circulate the nutrient solution 10 respectively, and the liquid inlet pipe 7 above the liquid tank 6 is provided with There are water pumps 5 and solenoid valves 9, and the liquid inlet pipe 7 and the liquid outlet pipe 8 at the upper and lower ends of the cultivation tank 1 are provided with solenoid valves 9, and the solenoid valves 9 are connected to the industrial computer 3 through connecting lines, and the industrial computer 3 is externally connected to the solar panel. 2;

[0022] The bottom surface of the cultivation tank 1 is connected with the low liquid return pipe 801 and the high liquid return pipe 802 respectively, the top surface of the low liquid return pipe 801 is f...

Embodiment 2

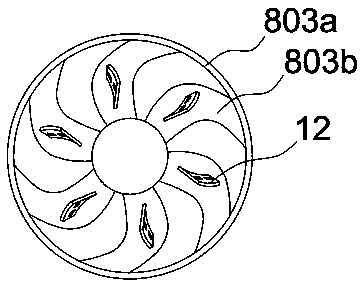

[0029] The splitter plate 12b is made of carbon fiber composite material, which is composed of the following components and parts by weight: 14.5 parts of polypropylene copolymer, 16 parts of carbon fiber, 6 parts of maleic anhydride grafted polypropylene, maleic anhydride grafted EPDM rubber 7 parts, 10 parts of smoked sheet rubber, 0.8 parts of carbon black, 0.27 parts of rare earth, 6 parts of gelatin, and 0.35 parts by weight of (R)-4-methylcyclohexylene methyl in maleic anhydride grafted EPDM rubber Base copper and (S)-4-methylcyclohexylenemethyl copper, the mass ratio of the two is 88:0.7, (R)-4-methylcyclohexylenemethyl copper and (S)-4-methyl The special ratio of cyclohexylidene methyl copper can increase the compatibility of maleic anhydride grafted polypropylene and maleic anhydride grafted EPDM rubber, making the ternary system of copolymerized polypropylene, carbon fiber and smoked sheet rubber very Good synergistic effect, the reinforcement effect on composite mat...

Embodiment 3

[0031] During the actual use of the cultivation device for promoting plant growth of the present invention, for example, soilless cultivation of lettuce is carried out, and the nutrient solution 10 for the lettuce cultivation that is placed in the liquid tank 6 is placed, and the nutrient solution 10 is detected by line before the liquid tank 6 is placed. Adjust the EC and pH values to meet the predetermined requirements, and then set them in the industrial computer 3, for example, at 9 o'clock every day (the specific time depends on the cultivated plants) turn on the water pump 5 to extract the nutrient solution 10 in the liquid tank 6 through the liquid inlet pipe 7 Entering the cultivation tank 1, the electromagnetic valve 9 on the low-level liquid return pipe 801 below the cultivation tank 1 is in the closed state, the liquid outlet pipe 8 is in the open state, and the liquid level of the nutrient solution 10 in the cultivation tank 1 continues to rise until the high-level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com