Multi-joint heavy load mechanical arm driven by single-blade hydraulic swing oil cylinders

A hydraulic swing, single-blade technology, used in manipulators, program-controlled manipulators, joints, etc., can solve the problems of delayed work process, long development cycle, self-weight ratio, low power density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

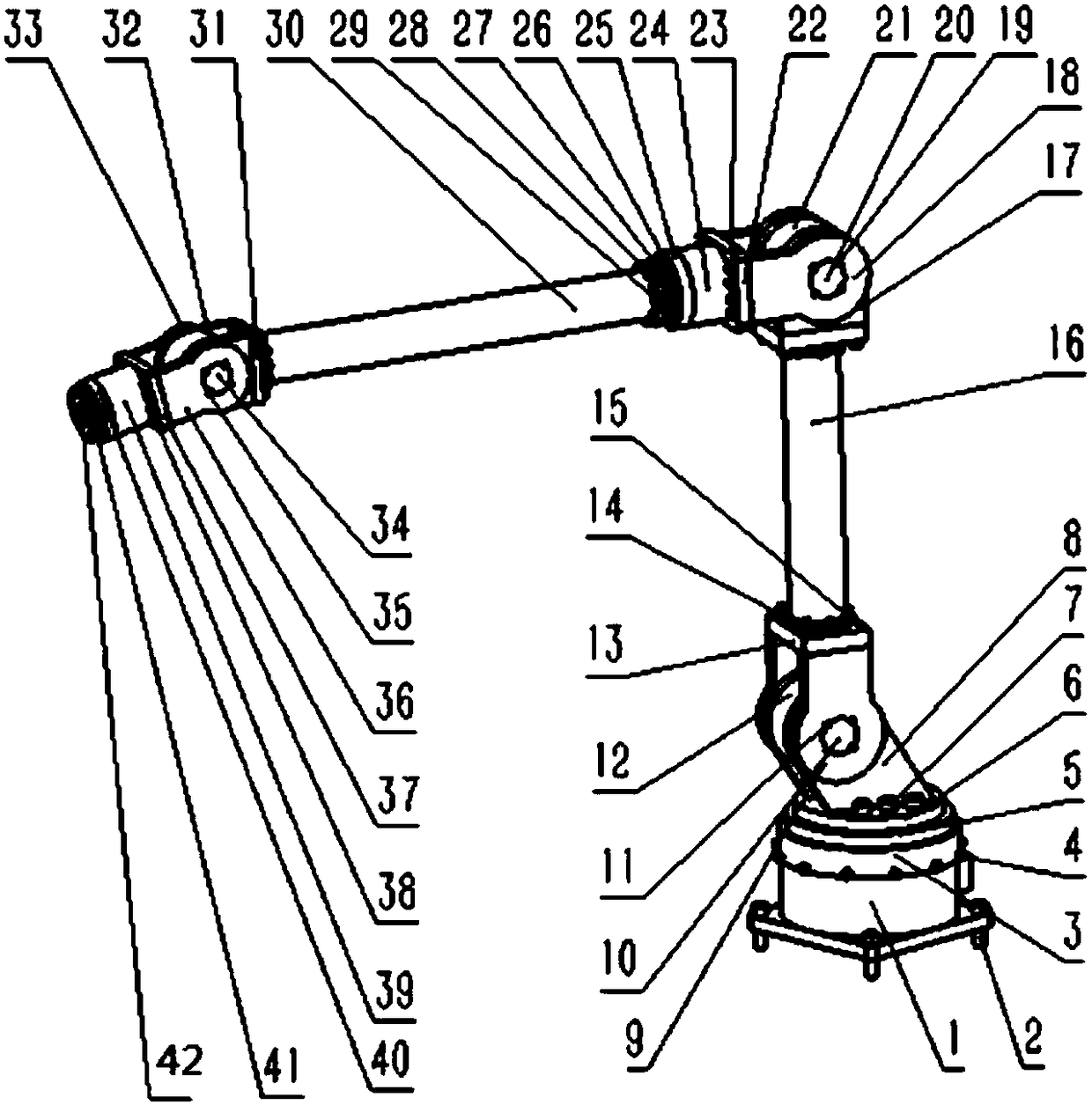

[0024] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as figure 1 As shown, the multi-joint heavy-duty mechanical arm of the present invention is mainly composed of a base module, a waist joint module, a shoulder joint module, a wrist joint module, a large arm, a small arm, flanges, and bolts composed of six single-blade hydraulic swing cylinders. The J1 cylinder and J2 cylinder, the J3 cylinder and the J4 cylinder, the J5 cylinder and the J6 cylinder are all vertically arranged to form the waist joint module, the shoulder joint module and the wrist joint module respectively. The installation of the J1 cylinder and related parts In the base, the positioning bolts of the base can be connected with the ground or the workbench according to the work requirements.

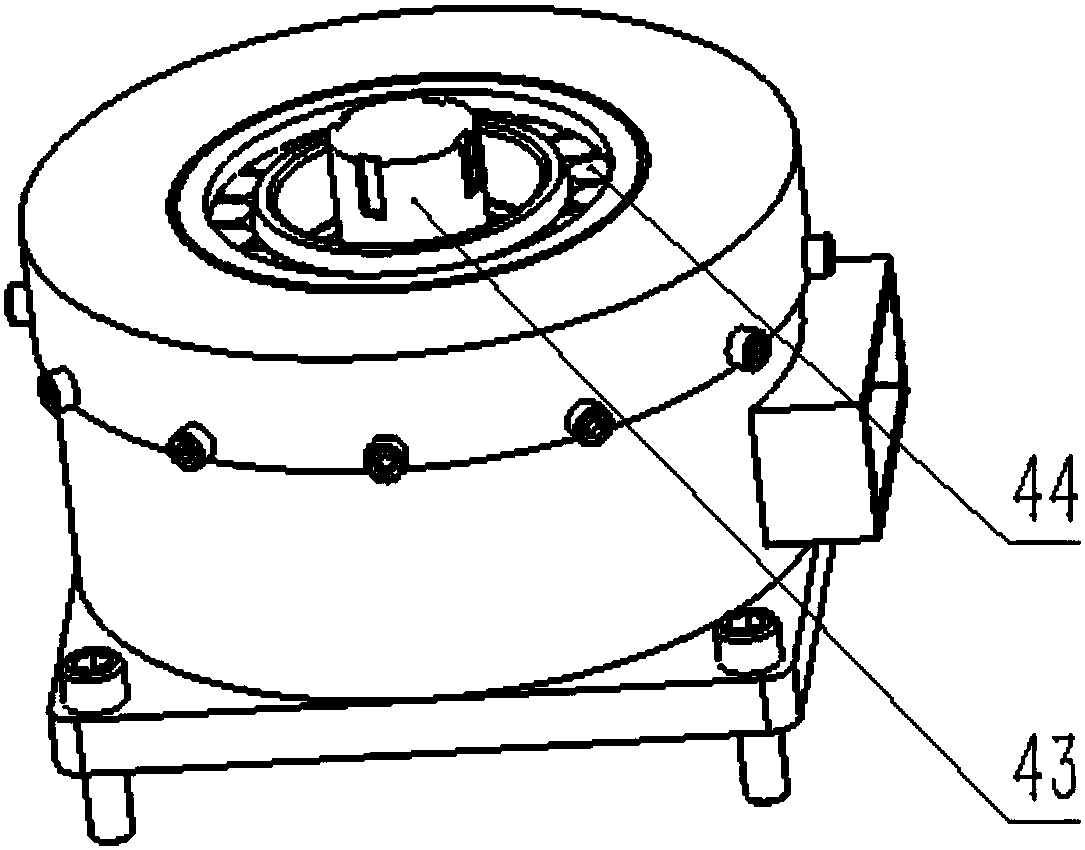

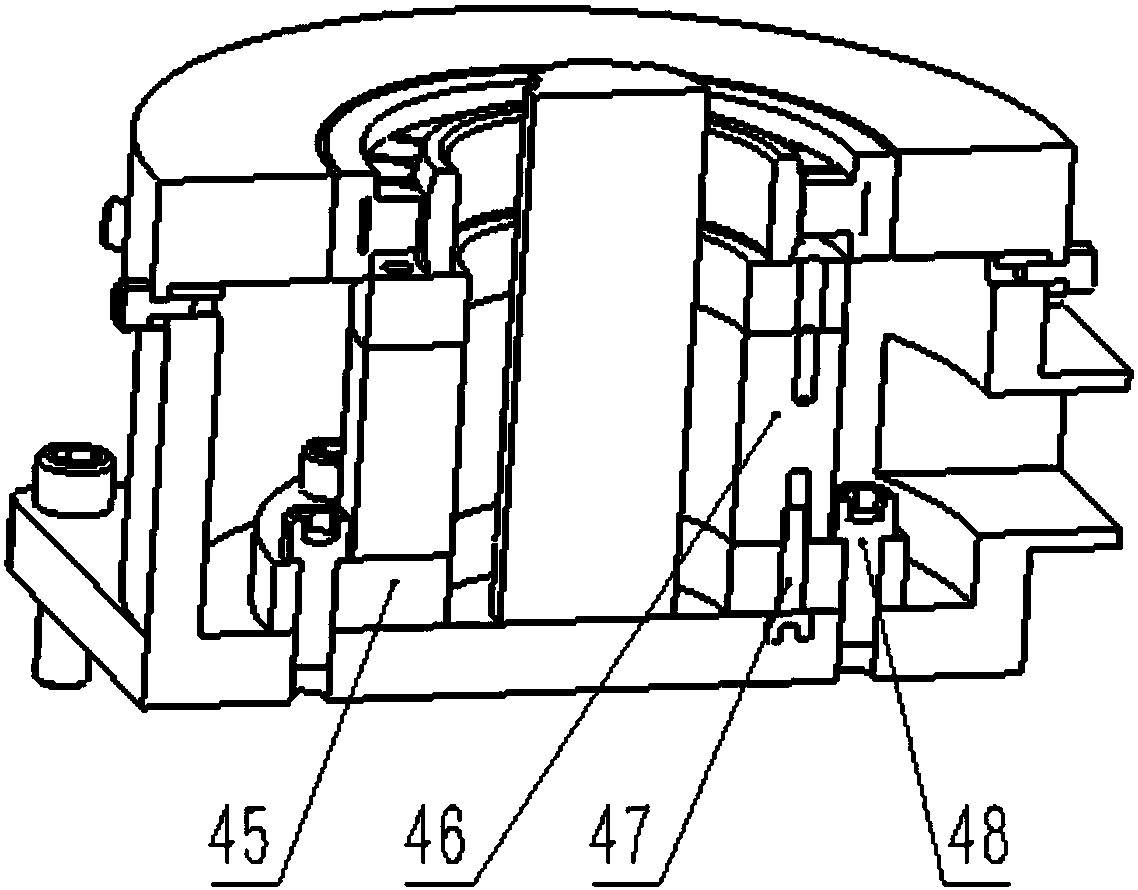

[0025] figure 2 and image 3 Shown are the base module and the sectional view of the base module respectively, the J1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com