Assembling type building sleeve grouting material

A sleeve grouting and assembly technology, which is applied in the field of engineering materials, can solve the problems of unsatisfactory engineering needs, low initial fluidity, and short setting time, and achieve the effects of strong injectability, long setting time, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

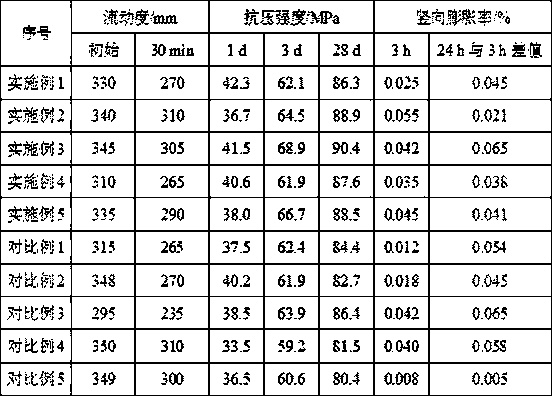

Examples

Embodiment 1

[0026] A prefabricated building sleeve grouting material, which is composed of the following raw materials in parts by weight: 30 parts of cement, 8 parts of ultrafine steel slag powder, 2 parts of phosphogypsum, 5 parts of ceramic microbeads, 30 parts of quartz sand, crushed nickel slag sand 30 parts, 0.05 parts of retarding superplasticizer, 0.1 part of strengthening agent, 0.5 parts of shrinkage reducing expansion component, 0.005 parts of defoaming agent, and 0.005 parts of xanthan gum.

[0027] The cement is ordinary Portland cement.

[0028] The particle size of the ultra-fine steel slag powder is 3-5 um.

[0029] The phosphogypsum is the waste residue discharged during the wet process of phosphoric acid production in the phosphorus chemical industry.

[0030] The quartz sand is quartz particles obtained by crushing quartz stone, and the particle size is less than 2.36 mm.

[0031] The crushed nickel slag sand is obtained by crushing the nickel slag produced in the pro...

Embodiment 2

[0038] A prefabricated building sleeve grouting material, which is composed of the following raw materials in parts by weight: 40 parts of cement, 3 parts of ultrafine steel slag powder, 6 parts of phosphogypsum, 3 parts of ceramic microbeads, 50 parts of quartz sand, crushed nickel slag sand 20 parts, 0.5 parts of retarding superplasticizer, 0.05 parts of strengthening agent, 2 parts of shrinkage reducing expansion component, 0.001 part of defoamer, 0.01 part of xanthan gum.

[0039] The cement is P.O 52.5 cement.

[0040] The particle size of the ultra-fine steel slag powder is 3-5 um.

[0041] SO in the phosphogypsum 3 Content ≥ 38%, 0.05% ≤ soluble phosphorus content ≤ 0.3%, 0.005% ≤ soluble fluorine content ≤ 0.03%.

[0042] The quartz sand is quartz particles obtained by crushing quartz stone, and the particle size is less than 2.36 mm.

[0043] The crushed nickel slag sand is obtained by crushing the nickel slag produced in the process of smelting nickel-iron alloy w...

Embodiment 3

[0049] A prefabricated building sleeve grouting material, which is composed of the following raw materials in parts by weight: 35 parts of cement, 5 parts of ultrafine steel slag powder, 4 parts of phosphogypsum, 4 parts of ceramic microbeads, 40 parts of quartz sand, crushed nickel slag sand 25 parts, 0.2 parts of retarding superplasticizer, 0.08 parts of reinforcing agent, 1.2 parts of shrinkage reducing expansion component, 0.003 parts of defoaming agent, and 0.008 parts of xanthan gum.

[0050] The cement is P.O 52.5 cement.

[0051] The ultra-fine steel slag powder is obtained by grinding the steel slag to a particle size of 3-5 um by means of a jet mill.

[0052] SO in the phosphogypsum 3 Content ≥ 38%, 0.05% ≤ soluble phosphorus content ≤ 0.3%, 0.005% ≤ soluble fluorine content ≤ 0.03%.

[0053] The ceramic microbeads are solid ceramic microbeads with a particle diameter of 1-40 um.

[0054] The quartz sand is quartz particles obtained by crushing quartz stone, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com