Multi-aldehyde-group amphoteric polyurethane retanning agent and preparation method thereof

A technology of polyurethane and retanning agent is applied in the field of retanning agent, which can solve the problems of influence, lack of fullness and discoloration of the leather, and achieve the effects of improving the stability of heat and humidity resistance, improving the reactivity, and improving the filling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

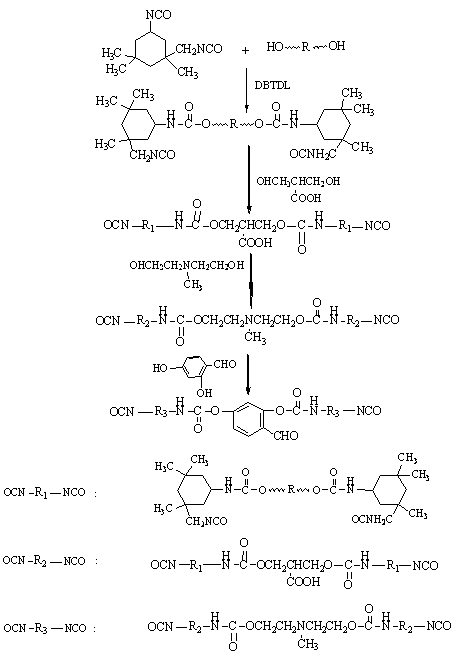

[0016] The preparation method of the amphoteric aldehyde polyurethane retanning agent that the present invention relates to, in N 2 Under the protection of isophorone diisocyanate and polytetrahydrofuran under the action of a catalyst, the prepolymerization reaction is carried out, and the chain extender: 2,2-hydroxymethylpropionic acid, N-methyldiethanolamine and 2,4 - Dihydroxybenzaldehyde is added to the system to react for a certain period of time, then the temperature is lowered to neutralize and emulsify. Specifically include the following steps:

[0017] Step 1: Firstly, 0.04 mole of isophorone diisocyanate and 0.01 mole of polytetrahydrofuran were mixed in N 2 Mix evenly under the protection of the catalyst, add two drops of catalyst, react at 40~50°C for 0.3~0.5h, raise the temperature to 70°C for 1h.

[0018] Step 2: Then raise the temperature of the system to 70-80°C, add 0.0086 moles of 2,2-dimethylolpropionic acid and 0.0049 moles of N-methyldiethanolamine to th...

Embodiment 1

[0021] Step 1: Firstly, 0.04 mole of isophorone diisocyanate and 0.01 mole of polytetrahydrofuran were mixed in N 2 Under the protection of the mixture, mix evenly, add two drops of catalyst, react at 40°C for 0.5h, then raise the temperature to 70°C for 1h.

[0022] Step 2: Then raise the temperature of the system to 70° C., add 0.0086 mol of 2,2-dimethylolpropionic acid and 0.0049 mol of N-methyldiethanolamine into the system of step 1 to react for 3 h.

[0023] Step 3: Finally, add 0.0042 moles of 2,4-dihydroxybenzaldehyde into the reaction system of step 3 and keep the temperature constant for 3 hours. After cooling down to 40°C, add 0.0080 moles of triethylamine to neutralize for 0.5 hours, then add distilled water to stir and emulsify at high speed. A polyaldehyde-based amphoteric polyurethane retanning agent is obtained.

Embodiment 2

[0025] Step 1: Firstly, 0.04 mole of isophorone diisocyanate and 0.01 mole of polytetrahydrofuran were mixed in N 2 Under the protection of the mixture, mix evenly, add two drops of catalyst, react at 42°C for 0.45h, then raise the temperature to 70°C for 1h.

[0026] Step 2: Then the temperature of the system was raised to 73°C, and 0.0086 moles of 2,2-dimethylolpropionic acid and 0.0049 moles of N-methyldiethanolamine were reacted for 2.8 hours.

[0027] Step 3: Finally, add 0.0063 moles of 2,4-dihydroxybenzaldehyde to the reaction system of step 3 and keep the temperature constant for 2.8 hours. After cooling down to 40°C, add 0.0086 moles of triethylamine for neutralization for 0.5 hours, then add distilled water High-speed agitation and emulsification to obtain polyaldehyde-based amphoteric polyurethane retanning agent.

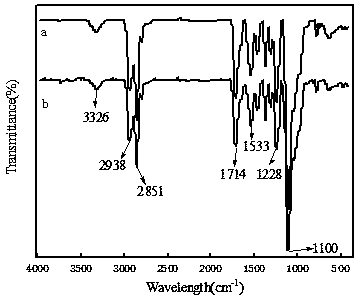

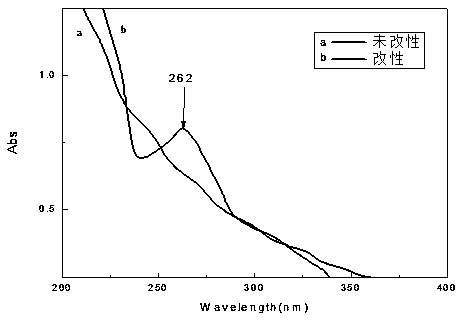

[0028] Embodiment 2 is carried out the detection of infrared and ultraviolet, figure 2 It is the infrared spectrogram of Example 2, the absorption pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com