Bean pulp protein adhesive and preparation method thereof

An adhesive and soybean meal technology, applied in the field of soybean meal protein, can solve problems such as unstable bonding quality, low reactivity, and poor water-resistant bonding performance, and achieve no harmful substance release, high product reactivity, and increased reaction effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

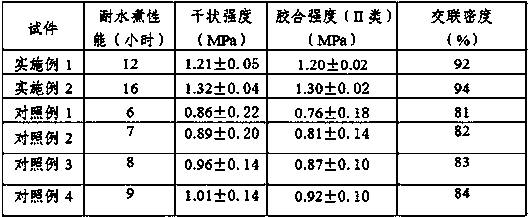

Examples

Embodiment 1

[0025] Example 1

[0026] The present embodiment provides a preparation method of a soybean meal protein adhesive, and the adhesive is prepared according to the following weight ratios:

[0027] Demineralized water 75 kg

[0028] Defatted Soy Protein Powder 25 kg

[0029] EMIBF 4 3kg

[0030] Nano calcium carbonate 1kg

[0031] Urea 2kg

[0032] Crosslinker 4Kg

[0033] Among them, defatted soybean protein powder with a protein content of more than 52% was purchased from Huifu Cereals and Oils Co., Ltd.; other materials were purchased from Beijing Chemical Reagent Co., Ltd.

[0034] The present embodiment also provides the preparation method of the above-mentioned adhesive, and the specific preparation steps are as follows:

[0035] (1) Weigh the components according to the weight ratio, disperse the protein powder and urea evenly in the dispersion medium water, and stir at 20°C for 20 minutes;

[0036] (2) adding nano calcium carbonate to the mixture obtained in step...

Embodiment 2

[0039] The present embodiment provides a preparation method of a soybean meal protein adhesive, and the adhesive is prepared according to the following weight ratios:

[0040] Demineralized water 75 kg

[0041] Defatted Soy Protein Powder 25 kg

[0042] EMIBF 4 4kg

[0043] Nano calcium carbonate 2kg

[0044] Urea 4kg

[0045] Crosslinker 5kg

[0046] Among them, defatted soybean protein powder with a protein content of more than 52% was purchased from Huifu Cereals and Oils Co., Ltd.; other materials were purchased from Beijing Chemical Reagent Co., Ltd.

[0047] The preparation method of the adhesive described in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com