Material transportation robot

A technology of robots and materials, applied in the directions of manipulators, joints, chucks, etc., can solve the problems of large changes in the processing cycle of the manipulator, difficulty in matching the load capacity with multiple equipment, and production stoppage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

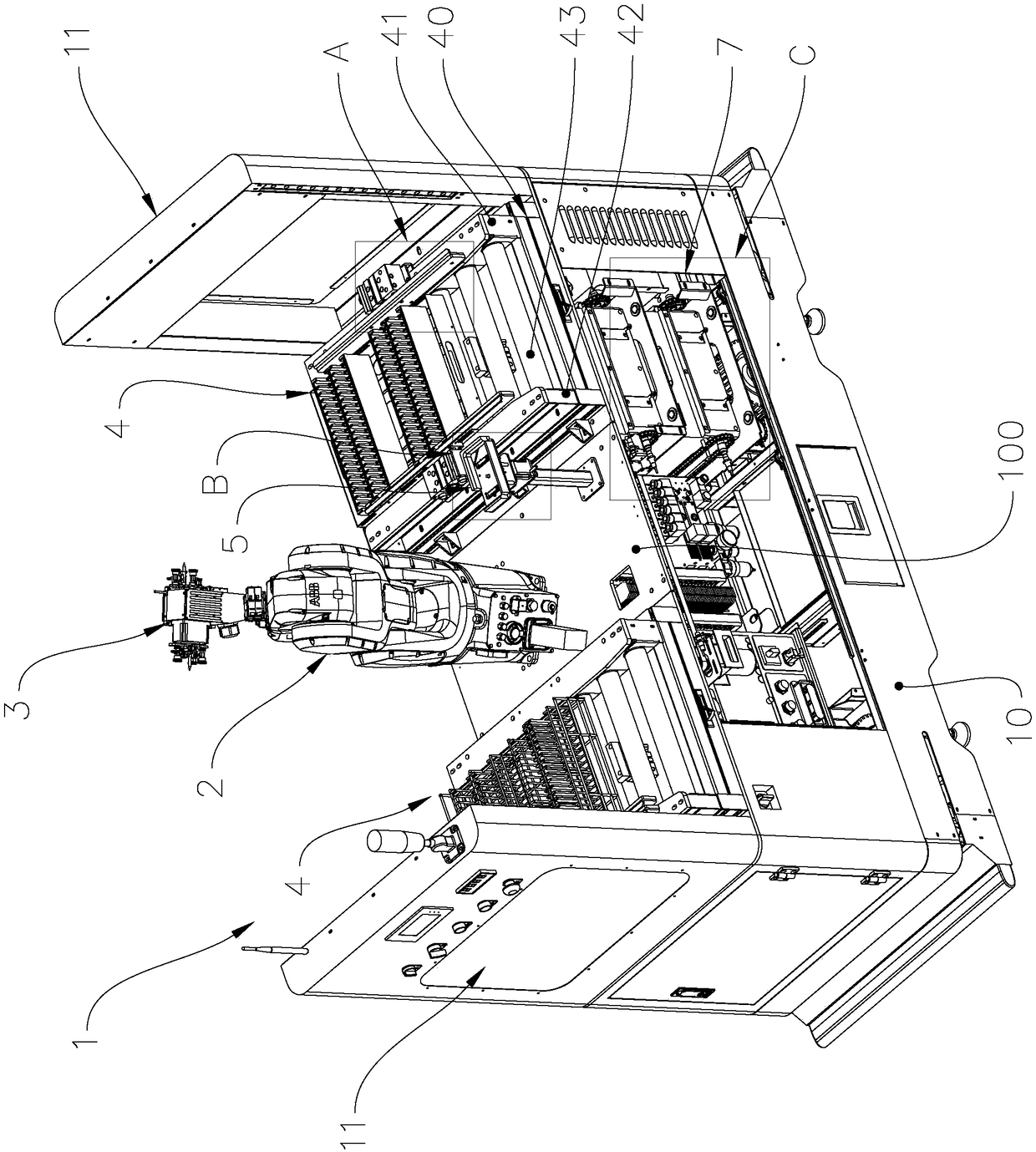

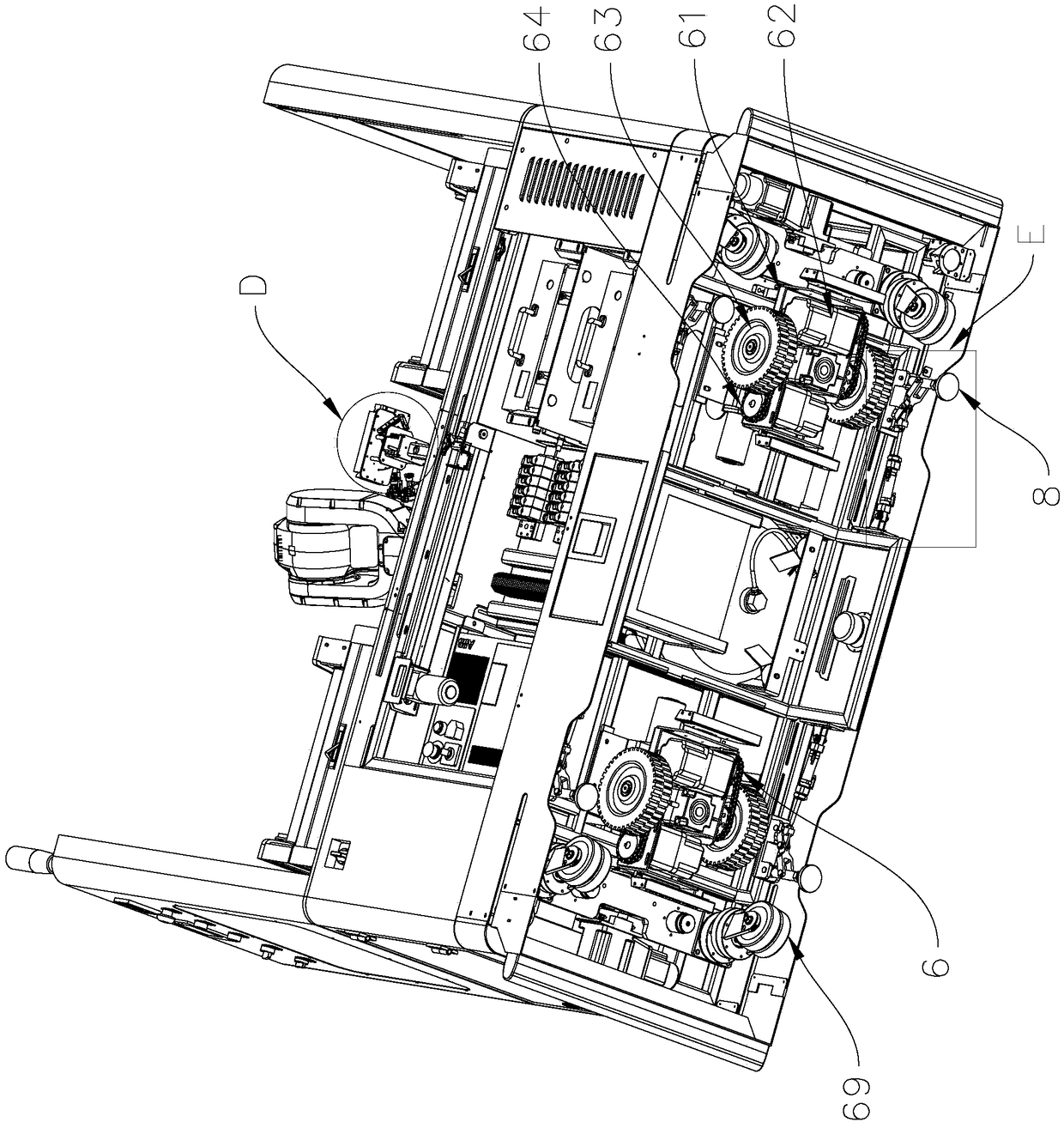

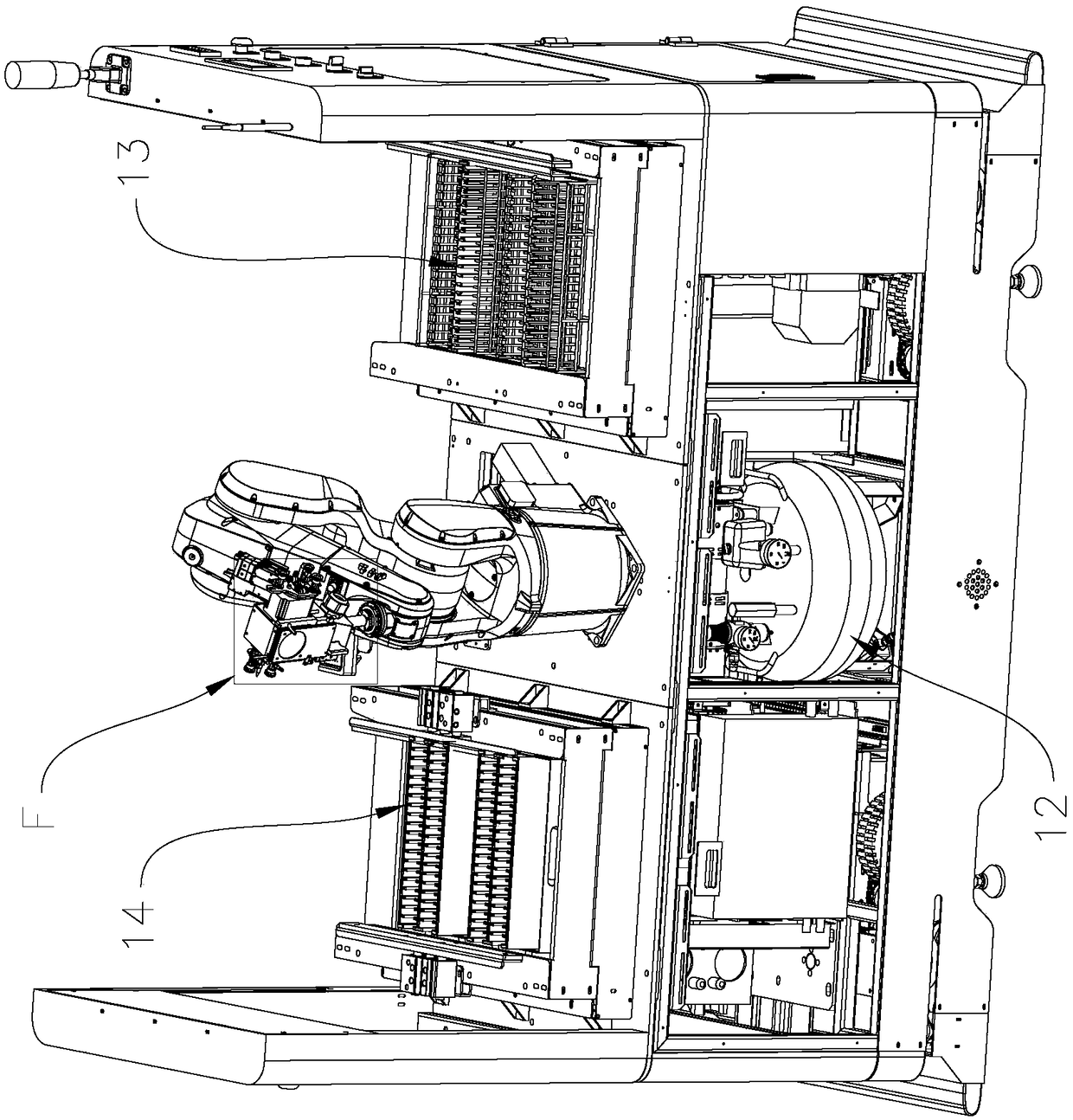

[0041] Example of Material Transportation System

[0042] see figure 1 and figure 2 , figure 1 and figure 2 They are the structural diagrams of different perspectives of the material handling robot. The material transport system includes a material transport robot and a battery replacement robot for battery replacement and workpiece loading and unloading of the material transport robot. The material transport robot provided by the present invention is an AGV material transport robot, that is, a transport vehicle with an automatic guiding function. The material transport robot 1 comprises a main body 10, the material transport robot 1 has a mechanical arm 2, a transport path device 4 and a temporary storage position device 5 on the working surface 100 of the main body 10, and the end of the mechanical arm 2 is provided with a manipulator 3; The bottom of the main body 10 is provided with a load-bearing wheel assembly, two sets of driving wheel assemblies 6 and four posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com