Plug-in type single-motor hybrid electric vehicle transmission

A hybrid vehicle and transmission technology, which is applied in the arrangement of multiple different prime movers of power units, pneumatic power units, and general power units, etc., can solve the problem of difficulty in guaranteeing motors, limited speed regulation range, and loss of mechanical energy to electrical energy. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

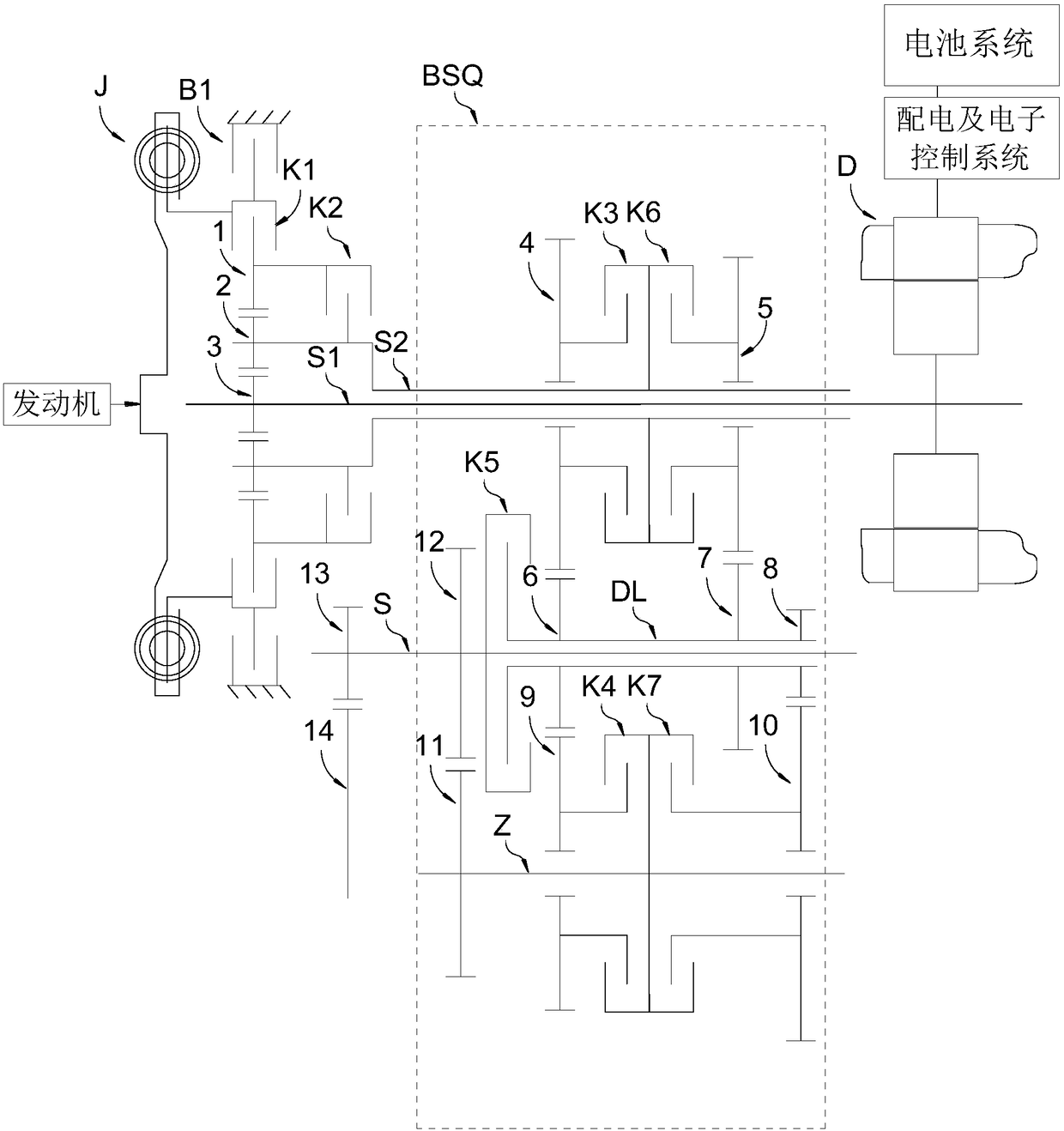

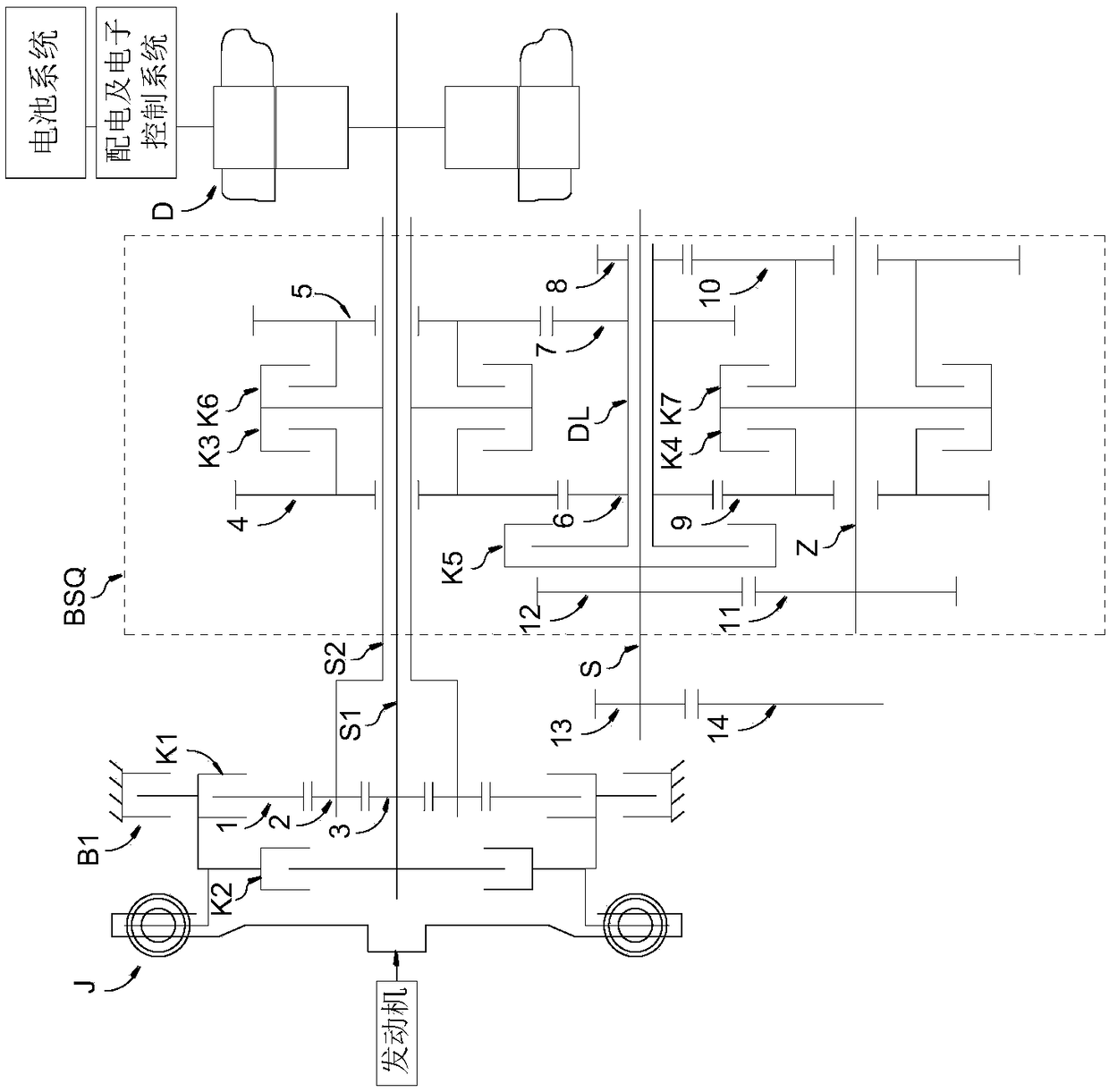

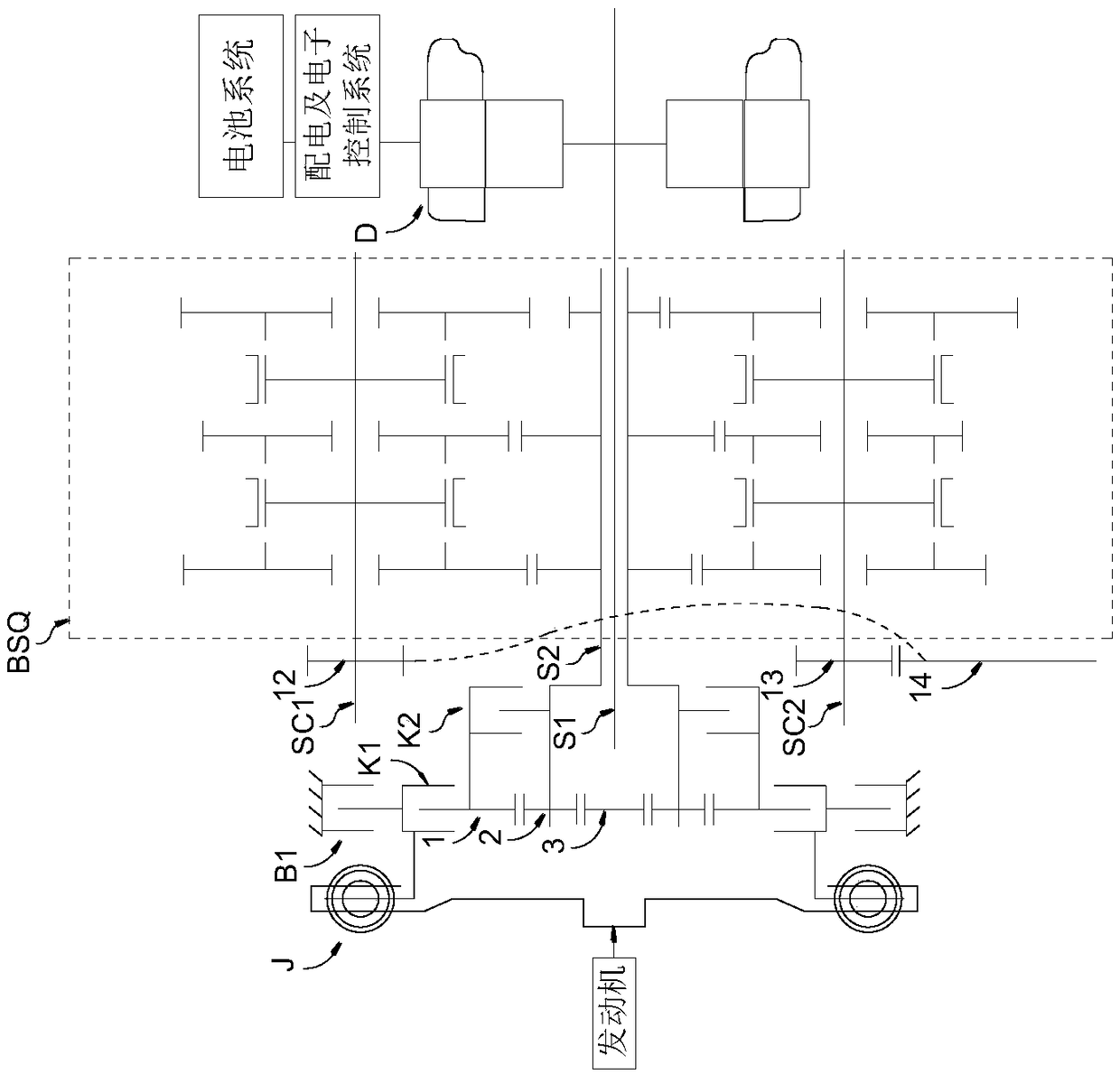

[0018] figure 1It is a schematic structural diagram of the first embodiment of the plug-in single-motor hybrid electric vehicle transmission of the present invention, the solution of the first embodiment is the preferred solution of the present invention, and the first implementation of the plug-in single-motor hybrid electric vehicle transmission of the present invention The mechanical transmission system BSQ in the example adopts the structural scheme of the 6-speed MAT automatic transmission inside, as shown in the figure, the plug-in single-motor hybrid vehicle transmission of the present invention includes a flywheel shock absorber J arranged between the transmission and the engine, The engine connection clutch K1 that controls the connection between the engine and the transmission, the planetary gear set that adjusts the power flow of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com