Composite barrier coated paper and processing method thereof

A processing method and technology for coated paper, which can be used in paper, papermaking, specialty paper, etc., and can solve the problems of paper moisture loss, affecting coating adhesion, paper flexibility, and poor product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

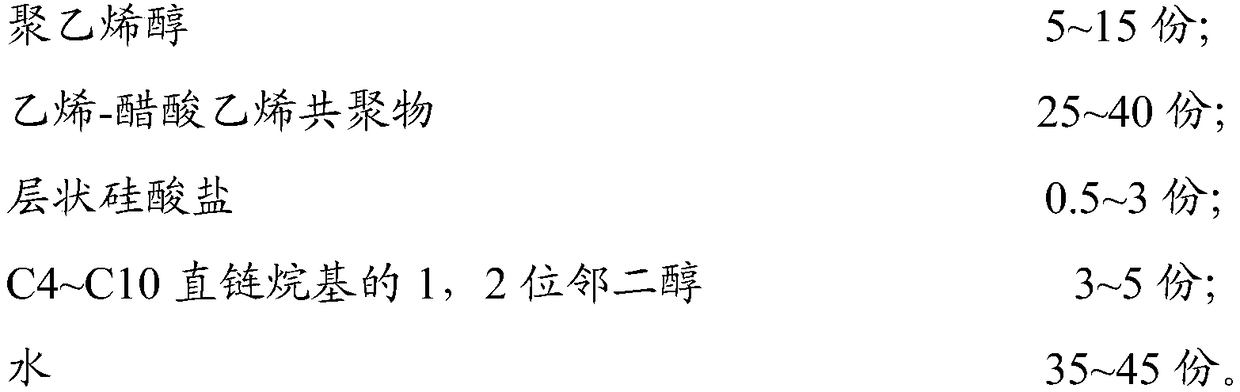

[0077] (1) Coatings that provide a composite barrier coating layer:

[0078] Stir 0.5kg of bentonite and 35kg of water evenly at a speed of 650r / min to obtain a pre-batch.

[0079] Stir the above pre-mixture, 10kg of polyvinyl alcohol, 25kg of ethylene-vinyl acetate copolymer and 3kg of 1,2-butanediol evenly at a speed of 380r / min to obtain a coating.

[0080] (2) After unwinding the base paper, use the above coatings to coat the front and back of the base paper respectively (the coating amount is 5g / m 2 ), and dried at 100°C to obtain the base paper.

[0081] (3) After the film is unrolled, the film is glued (the amount of glue on the film is 5.5g / m 2 ) to obtain a coated film.

[0082] (4) After laminating the coating film and the base paper, varnish was applied, dried at 110° C., cooled, and rolled to obtain a composite barrier coated paper.

[0083] The composite barrier coated paper prepared in Example 1 was stored for 8 months for measurement. Compared with the base ...

Embodiment 2

[0091] (1) Coatings that provide a composite barrier coating layer:

[0092] Stir 3kg of montmorillonite and 45kg of water evenly at a speed of 750r / min to obtain a pre-mixture.

[0093] The polyvinyl alcohol (number average molecular weight is 2000) of above-mentioned pre-batching, 5kg, 40kg degree of hydrolysis is the ethylene-vinyl acetate copolymer (number average molecular weight is 1200) of 45%, 2.5kg1, 2-butanediol and 2.5kg1, 2-Hexanediol was stirred evenly at a speed of 440r / min to obtain a coating.

[0094] (2) After unwinding the base paper, use the above coatings to coat the front and back of the base paper respectively (the coating amount is 5.5g / m 2 ), and dried at 110°C to obtain the base paper.

[0095] (3) After the film is unrolled, the film is glued (the amount of glue on the film is 6.0g / m 2 ) to obtain a coated film.

[0096] (4) After laminating the coating film and the base paper, varnish was applied, dried at 120° C., cooled, and rolled to obtain a ...

Embodiment 3

[0099] (1) Coatings that provide a composite barrier coating layer:

[0100] 1.4kg of montmorillonite, 0.6kg of kaolin and 40kg of water were evenly stirred at a speed of 700r / min to obtain a pre-mixture.

[0101] The polyvinyl alcohol (number average molecular weight is 2000) of above-mentioned pre-batching, 15kg, 30kg degree of hydrolysis are 60% ethylene-vinyl acetate copolymer (number average molecular weight is 1150) and 4kg of 1,2-pentanediol in 400r Stir evenly at a rate of 1 / min to obtain a coating.

[0102] (2) After unwinding the base paper, use the above coatings to coat the front and back of the base paper respectively (the coating amount is 4.5g / m 2 ), and dried at 80°C to obtain the base paper.

[0103] (3) After the film is unrolled, the film is glued (the amount of glue on the film is 5.5g / m 2 ) to obtain a coated film.

[0104] (4) After laminating the coating film and the base paper, varnish was applied, dried at 90° C., cooled, and rolled to obtain a com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glue amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com