Method for treating radioactive solid organic waste

An organic waste and radioactive technology, applied in radioactive purification, nuclear engineering, etc., can solve the problems of unsolved radioactive solid organic waste transportation, small amount of radioactive waste treatment, separation of radionuclide, etc., to achieve overall concise and effective, waste The effect of increasing volume reduction ratio and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: the processing of radioactive solid organic waste (one)

[0043] (1) Use a colloid mill to pulverize 10 kg of radioactive waste resin for 10 minutes until the cumulative pulverization of the radioactive waste resin is 10-15 times, and the particle size of the radioactive waste resin reaches 5-10 μm. Determination of initial TOC of crushed radioactive waste resin R = 119850 ppm.

[0044] (2) Adding Cu with a concentration of 0.1mol / L to the radioactive waste resin 2+ Catalyst (Cu(NO 3 ) 2 ) with stirring and heating. After the temperature reaches 90°C, slowly add hydrogen peroxide with a peristaltic pump. When the amount of hydrogen peroxide reaches 4.8L (corresponding mass is 5.3kg), stir for another 15-30 minutes. The dissolved radioactive waste resin solution was cooled and filtered, and 100 mL of propanol, a combustion aid, was added as a feed solution for supercritical water reaction.

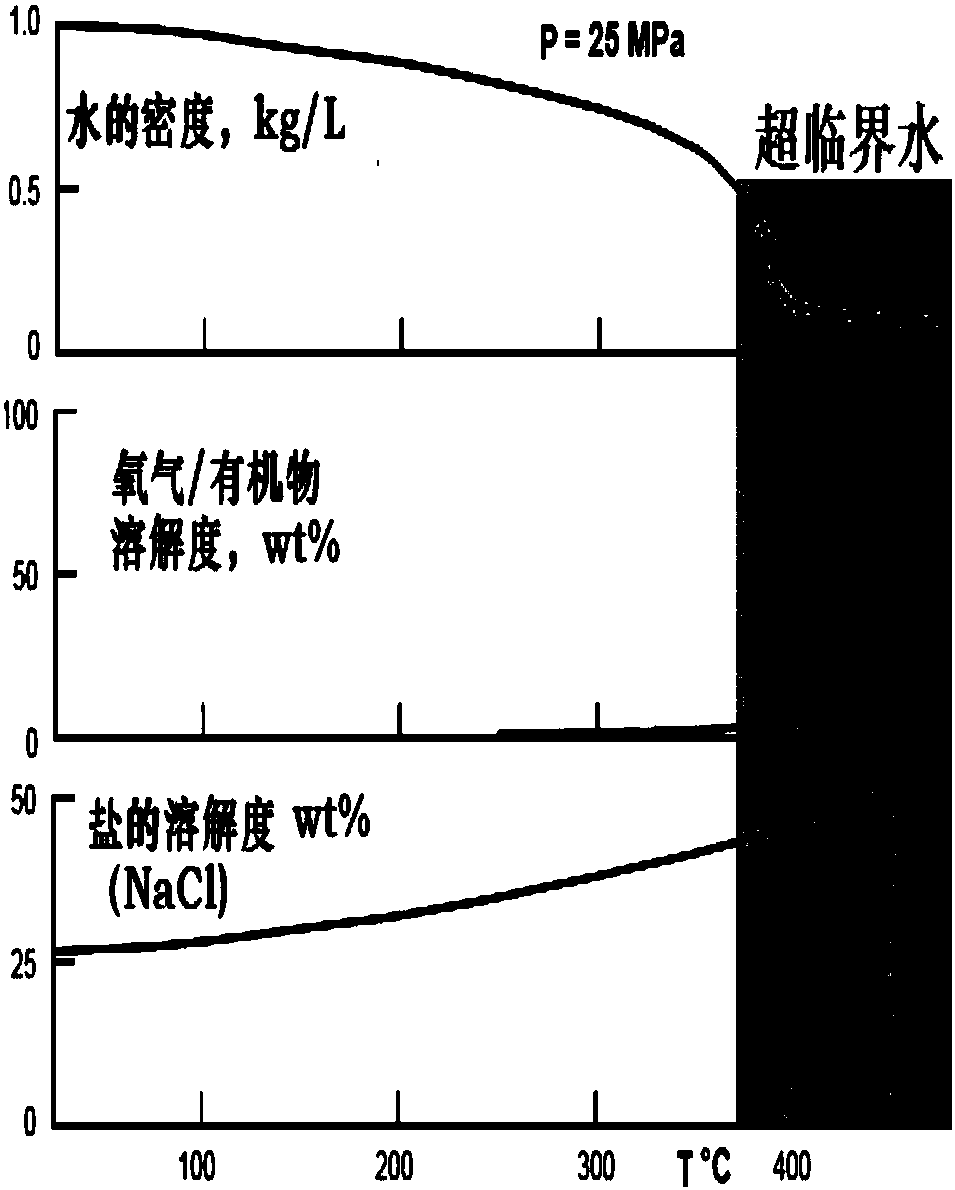

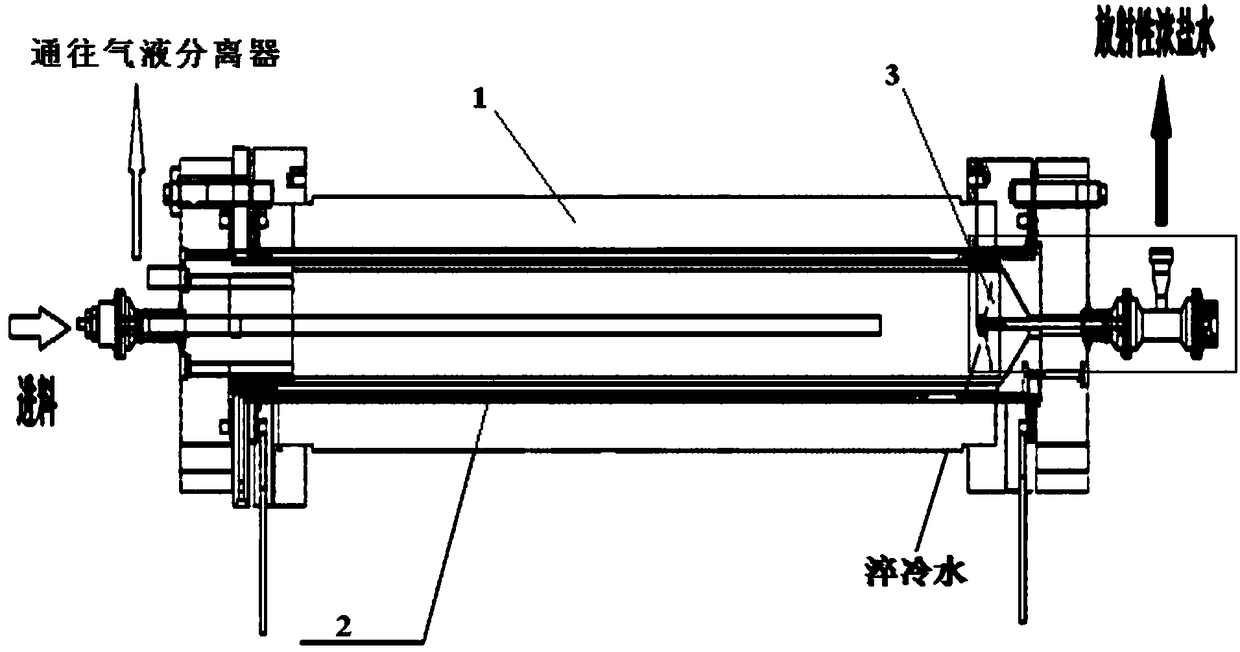

[0045] (3) Feed liquid and liquid oxygen are pumped into such...

Embodiment 2

[0048] Embodiment 2: the processing of radioactive solid organic waste (two)

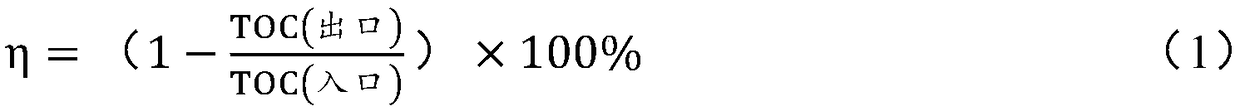

[0049] The processing method of radioactive solid organic waste is basically the same as embodiment 1, just cancels Cu in step (1). 2+ Addition of catalyst. Measured initial TOC R =99850ppm, the pH of the effluent liquid sampling is 3, and the TOC of the effluent liquid sampling is 3050ppm. According to the above formula (1), it can be obtained that η=96.95%.

Embodiment 3

[0050] Embodiment 3: the processing of radioactive solid organic waste (three)

[0051] The treatment method of radioactive solid organic waste is basically the same as that of Example 1, except that in step (3), the reaction temperature is changed to 800° C., and the reaction pressure is 10 MPa. Measured initial TOC R =109700ppm, the pH of the effluent liquid sampling is 3, and the TOC of the effluent liquid sampling is 34ppm. According to the above formula (1), it can be obtained that η=99.97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com