Metal powder core type heat resistant steel submerged arc welding wire and welding flux for 650 DEG C supercritical thermal power plant

A technology for metal powder cores and thermal power units, applied in metal processing equipment, welding media, welding equipment, etc., to achieve good physical and chemical properties, good welding process performance, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

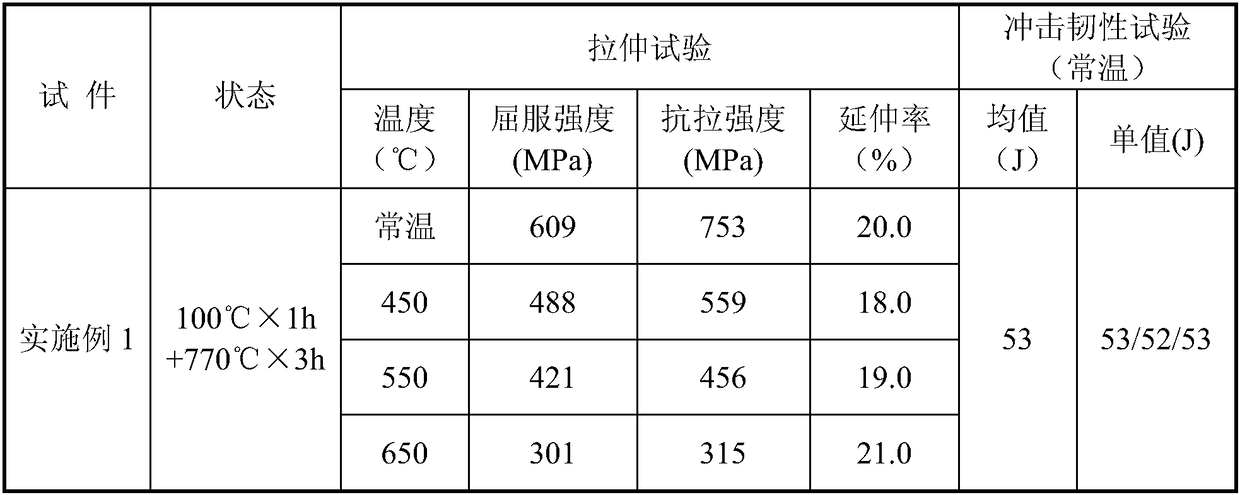

[0040] The technical solutions of the present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these examples.

[0041] A metal powder-cored heat-resistant steel submerged arc welding wire and flux for ultra-supercritical thermal power units at 650°C, using fluorine-alkali flux and metal powder-cored welding wire;

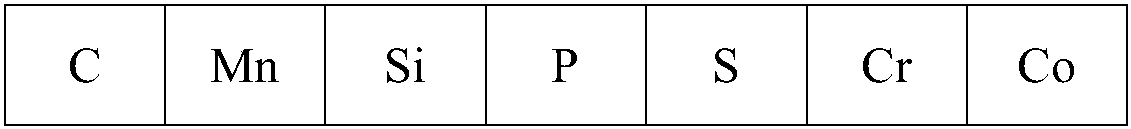

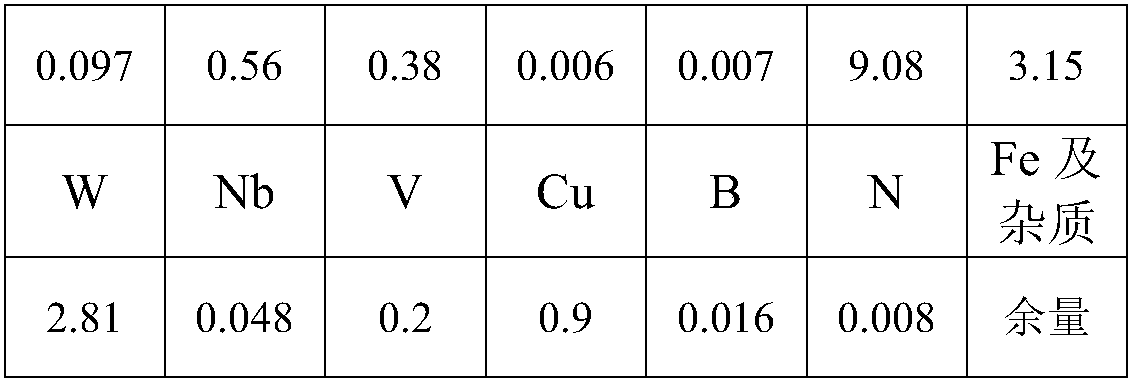

[0042] In terms of weight percentage, the metal powder cored wire composition content is: ferrochromium: 4-11%; metal manganese: 0.5-3%; ferrosilicon ≤ 4%; metal chromium: 35-40%; cobalt powder: 12- 16%; Tungsten powder: 12-16%; Niobium powder: 0.08-0.36%; Vanadium iron: 0.9-1.5%; Metal copper: 2.5-5.5%; Boron iron: 1-3%; Compound ≤ 1%; the balance is metallic iron;

[0043] In terms of weight percentage, the composition content of the fluorine-alkali type flux is: CaF 2 :20-35; Al 2 o 3 : 10-30; SiO 2 : 5-20; CaO: 25-40; ZrO 2 : 0.5-2; Na 2 O: 0.5-3; K 2 O: 1-5;

[0044] In terms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com