Hydrolysis-resistant polyurethane shoe sole and preparation method thereof

A polyurethane and hydrolysis-resistant technology, applied in the field of shoe sole materials, can solve problems such as poor hydrolysis resistance, achieve the effects of improving hydrolysis resistance, avoiding degradation, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

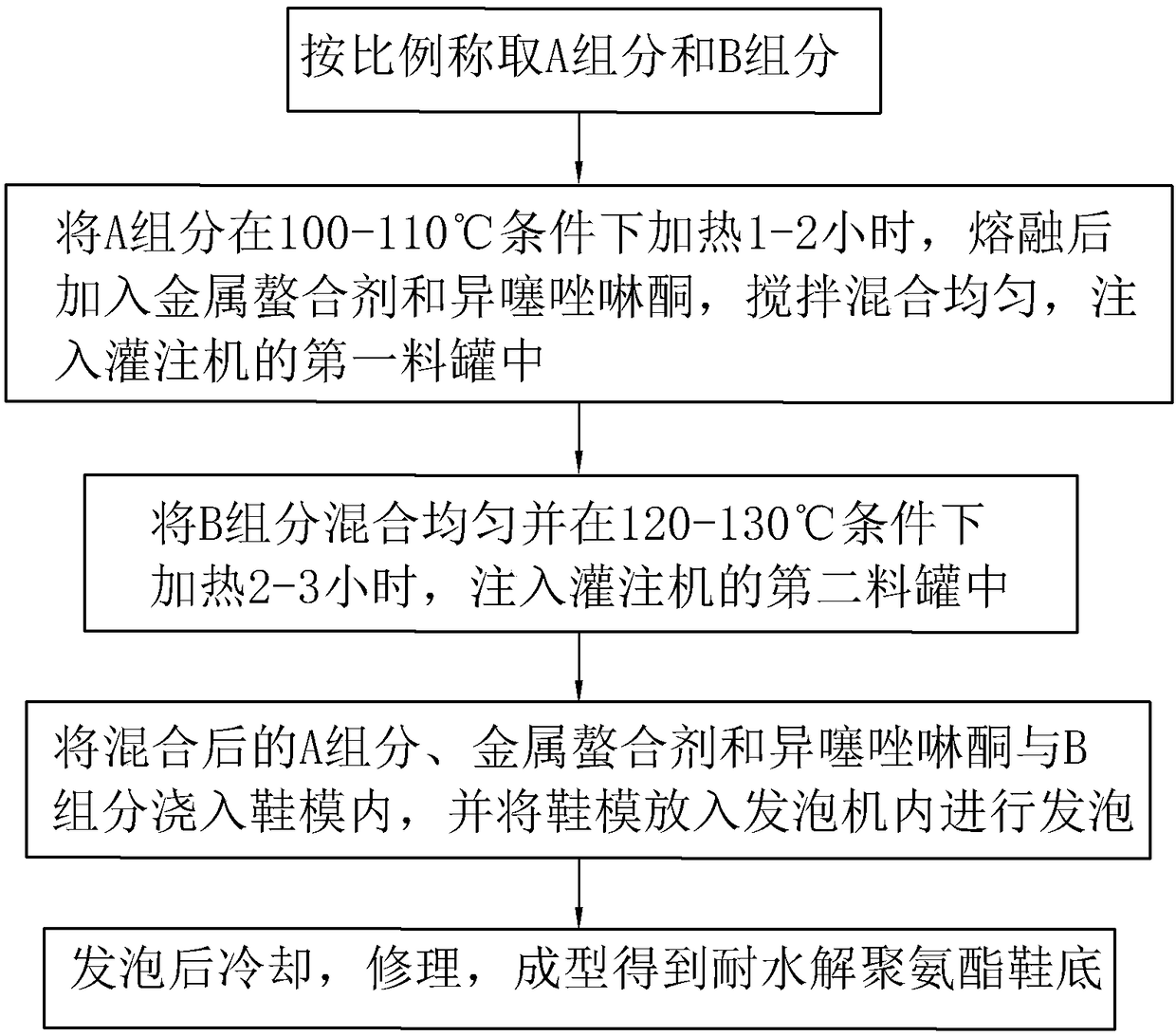

[0051] Embodiment 1: A kind of hydrolysis-resistant polyurethane shoe sole, each component and its corresponding parts by weight are as shown in Table 1, and its technological process refers to figure 1 , and obtained by the following steps:

[0052] Step 1, taking A component and B component in proportion;

[0053]Step 2: Heat component A at 100°C for 1 hour, add metal chelating agent and isothiazolinone after melting, stir and mix evenly, and pour it into the first tank of the pouring machine;

[0054] Step 3: Mix component B evenly and heat it at 120°C for 2 hours, and inject it into the second material tank of the filling machine;

[0055] Step 4, pour the mixed A component, metal chelating agent, isothiazolinone and B component into the shoe mold, and put the shoe mold into a foaming machine for foaming;

[0056] Step five, cooling after foaming, repairing and molding to obtain the hydrolysis-resistant polyurethane sole.

Embodiment 2-8

[0057] Example 2-8: A hydrolysis-resistant polyurethane shoe sole, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0058] Each component and parts by weight thereof in table 1 embodiment 1-8

[0059]

[0060]

Embodiment 9-16

[0061] Embodiments 9-16: A hydrolysis-resistant polyurethane shoe sole. The difference from Embodiment 1 is that each component and its corresponding parts by weight are shown in Table 2.

[0062] Each component and parts by weight thereof in table 2 embodiment 9-16

[0063]

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com