Radiation-proof thermal-insulation polymerized glass and preparation method thereof

A radiation-proof and glass technology, which is applied in the field of radiation-proof and heat-insulating polymer glass and its preparation, can solve the problem of uneven distribution of indium tin oxide, radiation-proof and heat-insulating polymer glass blocking infrared light and ultraviolet light, and indium tin oxide particles Easy to reunite and other problems, to achieve the effect of enhanced dispersion, high transparency, and increased transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

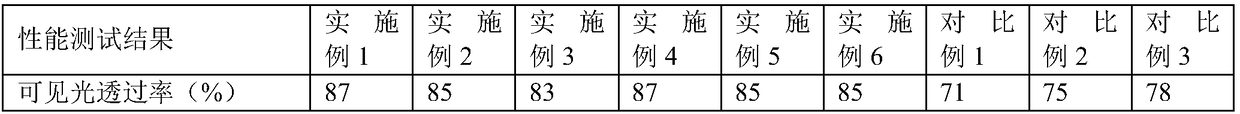

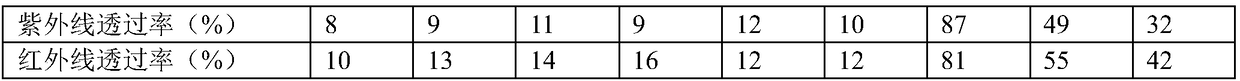

Examples

Embodiment 1

[0029] Indium tin oxide pre-dispersion: Take 28kg of indium tin oxide, 10kg of acryloxymethyltrimethoxysilane, 20kg of octyltrimethoxysilane, and 6kg of polyethylene wax and add it to 55kg of ethanol, wherein the particle size of indium tin oxide is 250nm, adjust the pH of the solution to 4, stir at 4250r / min, stir for 3.6h;

[0030] Premixing: Add 110kg of bisphenol A, 90kg of diphenyl carbonate, and 12kg of potassium hydroxide into the reactor. After pumping out the air in the reactor, raise the pressure of the reactor to 710Pa and the temperature to 145°C. After the raw materials are melted, react Still starts to stir, and stirring rate is 1150r / min, until there is no more distillate;

[0031] Polycondensation: Slowly add the indium tin oxide pre-dispersion to the reactor, then continue to heat up to 205°C, after the reactant becomes white and viscous, reduce the pressure of the reactor to 105Pa, raise the temperature of the reactor to 250°C, and react After 45 minutes, co...

Embodiment 2

[0034] Pre-dispersion of indium tin oxide: Take 26kg of indium tin oxide, 11kg of acryloxymethyltrimethoxysilane, 16kg of octyltrimethoxysilane, and 9kg of polyethylene wax and add them to 60kg of methanol, wherein the particle size of indium tin oxide is 200nm, adjust the pH of the solution to 5, the stirring rate is 4250r / min, stirring for 4h;

[0035] Premixing: Add 100kg of bisphenol A, 87kg of diphenyl carbonate, and 10kg of potassium hydroxide into the reactor. After pumping out the air in the reactor, raise the pressure of the reactor to 700Pa and the temperature to 150°C. After the raw materials are melted, react Still starts to stir, and stirring rate is 1300r / min, until there is no more distillate;

[0036] Polycondensation: Slowly add the indium tin oxide pre-dispersion to the reactor, and continue to heat up to 200°C. After the reactant becomes white and viscous, reduce the pressure of the reactor to 105Pa, raise the temperature of the reactor to 255°C, and react ...

Embodiment 3

[0039] Pre-dispersion of indium tin oxide: Take 30kg of indium tin oxide, 9kg of acryloxymethyltrimethoxysilane, 11kg of octyltrimethoxysilane, and 9kg of polyethylene wax and add them to 50kg of ethyl acetate. Among them, the particles of indium tin oxide The diameter is 300nm, the pH of the solution is adjusted to 4, the stirring rate is 4500r / min, stirring for 4h;

[0040] Premixing: Add 100kg of bisphenol A, 93kg of diphenyl carbonate, and 10kg of potassium hydroxide into the reactor. After pumping out the air in the reactor, raise the pressure of the reactor to 700Pa and the temperature to 150°C. After the raw materials are melted, react Still starts to stir, and stirring rate is 1000r / min, until there is no more distillate;

[0041] Polycondensation: Slowly add the indium tin oxide pre-dispersion to the reactor, and continue to heat up to 210°C. After the reactant becomes white and viscous, reduce the pressure of the reactor to 110Pa, raise the temperature of the reactor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com