Preparation method of durable type antirust emulsified oil

An anti-rust emulsified oil, durable technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor anti-rust performance, short anti-rust period of anti-rust emulsified oil, etc., to improve anti-rust performance and increase activation energy, the effect of metal ion concentration inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

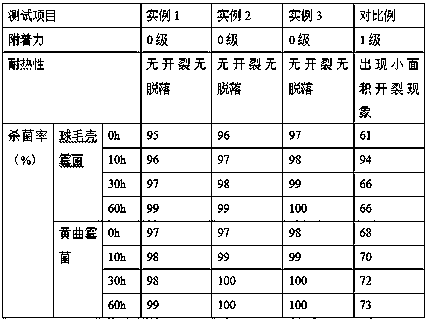

Examples

example 1

[0026]Take 400g of radix sorbifolium seed kernels and put them into a refiner for grinding for 30 minutes to obtain a seed kernel slurry, put the seed kernel slurry into an Erlenmeyer flask, and add 40mL of chlorinated Sodium solution, 4g cellulase and 200mL distilled water, put the Erlenmeyer flask into a water bath, heat up to 80°C, stir and react for 40min to obtain the seed kernel extract; put the seed kernel extract in an ultrasonic machine, Ultrasonic treatment at ℃ for 40 minutes, control the power of the ultrasonic machine to 150W, to obtain the ultrasonic treatment solution, put the ultrasonic treatment solution in a high-speed centrifuge at a speed of 2000r / min, centrifuge for 15 minutes, remove the lower layer of water, and collect the upper layer of slick oil. Xantho sorbifolium seed oil; put 60mL aniline and 50mL absolute ethanol into a three-necked flask equipped with a reflux condenser and a stirrer, start the stirrer, stir at a speed of 200r / min, and simultaneou...

example 2

[0028] Take 425g of radix radix radiata seed kernels and put them into a refiner for grinding for 35 minutes to obtain a seed kernel slurry, put the seed kernel slurry into an Erlenmeyer flask, and add 45mL of 15% chlorine dioxide to the Erlenmeyer flask. Sodium solution, 5g cellulase and 225mL distilled water, put the Erlenmeyer flask into a water bath, heat up to 85°C, stir and react for 45min to obtain the seed kernel extract; put the seed kernel extract into an ultrasonic machine, Ultrasonic treatment at ℃ for 43 minutes, control the power of the ultrasonic machine to 170W, to obtain the ultrasonic treatment solution, put the ultrasonic treatment solution in a high-speed centrifuge at a speed of 2250r / min, centrifuge for 17 minutes, remove the lower layer of water, and collect the upper layer of slick oil. Xantho sorbifolium seed oil; put 65mL of aniline and 53mL of absolute ethanol into a three-necked flask equipped with a reflux condenser and a stirrer, start the stirrer,...

example 3

[0030] Take 450g of radix radix radiata seed kernels and put them into a refiner for grinding for 40 minutes to obtain a seed kernel slurry, put the seed kernel slurry into an Erlenmeyer flask, and add 50mL of chlorinated Sodium solution, 6g cellulase and 250mL distilled water, put the Erlenmeyer flask into a water bath, heat up to 90°C, stir and react for 50min to obtain the seed kernel extract; put the seed kernel extract in an ultrasonic machine, Ultrasonic treatment at ℃ for 45 minutes, control the power of the ultrasonic machine to 200W, to obtain the ultrasonic treatment solution, put the ultrasonic treatment solution in a high-speed centrifuge at a speed of 2500r / min, centrifuge for 20 minutes, remove the lower layer of water, and collect the upper layer of slick oil. Xantho sorbifolium seed oil; put 70mL aniline and 55mL absolute ethanol into a three-necked flask equipped with a reflux condenser and a stirrer, start the stirrer, stir at a speed of 250r / min, and simultan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com