Energy-saving efficient two-phase anaerobic-aerobic coupling treatment process and system for kitchen wastes

A food waste and treatment system technology, applied in the direction of biomass post-treatment, biomass pre-treatment, chemical industry, etc., can solve the problem of COD effluent not up to standard, uneven distribution of internal circulation velocity field, acid-producing phase sludge loss, etc. problems, to achieve the effect of prolonging the hydraulic retention time, preventing scum and crusting, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] An energy-saving and efficient two-phase anaerobic-aerobic coupling treatment process for food waste, comprising the following steps:

[0055] S1: Sieve the food waste into food waste organic matter and food waste inorganic matter, and dilute the food waste organic matter and grind it into a slurry with a particle size below 3mm;

[0056] S2: fully mixing and stirring the slurry obtained in step S1 and the sludge previously added to the acid-producing digester in the acid-producing digester to obtain mixed fermentation broth, primary crude biogas and primary biogas slurry and residue;

[0057] S3: introducing the mixed fermented liquid obtained in step S2 into the methanogenic digester to carry out the fermentation process of methanogenic digester to obtain the sludge produced in the middle part of the methanogenic digester, the effluent produced in the upper part, the secondary crude biogas and the secondary biogas slurry and residue;

[0058] S4: Precipitate and conce...

Embodiment 2

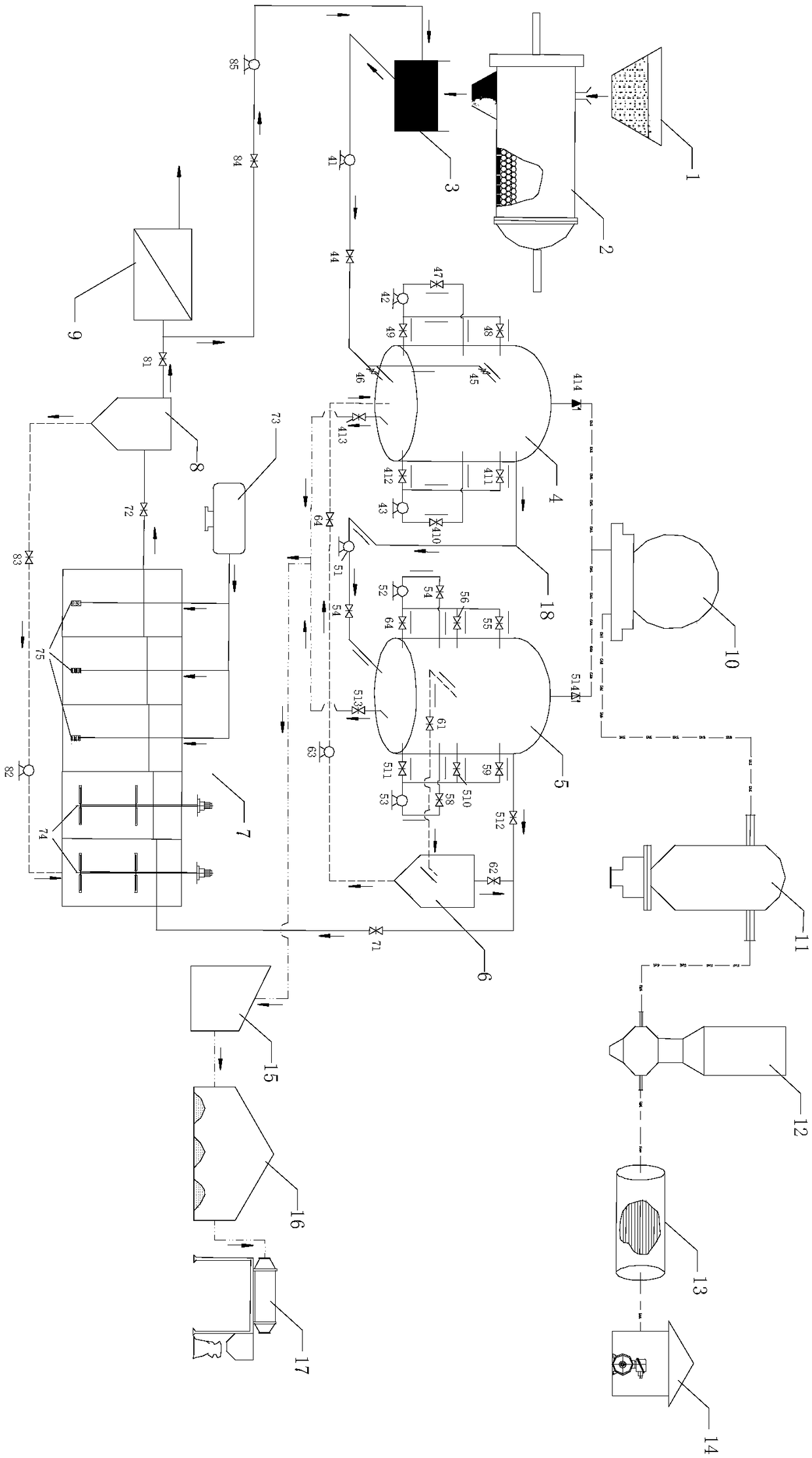

[0063] The energy-saving and high-efficiency two-phase anaerobic-aerobic coupling treatment system for kitchen waste according to the present invention mainly includes a pretreatment unit, an anaerobic treatment unit, an aerobic treatment unit, a biogas residue treatment unit, and a biogas purification and purification unit.

[0064] (1) Preprocessing unit

[0065] The pretreatment unit is equipped with a storage box, food waste grinding and separation equipment, and a discharge bin.

[0066] The storage box is used to hold the raw materials of food waste, and is provided with a discharge port connected with the food waste grinding and separation equipment. The grinding and separation equipment is used to separate the organic matter and the inorganic matter in the food waste output from the storage bin, and grind the organic matter into a slurry with a particle size below 3mm. The discharge bin is used to hold the food waste slurry output from the grinding and separation equi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com