Three-dimensional spacer structure electrothermal composite material and preparation method thereof

A composite material and electric heating technology, which is applied in the direction of textile, fabric, textile and paper making, can solve the problems of low thermal energy conversion efficiency, poor mechanical properties, non-humidity resistance, etc., and achieve the effect of improving heating efficiency, light weight and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

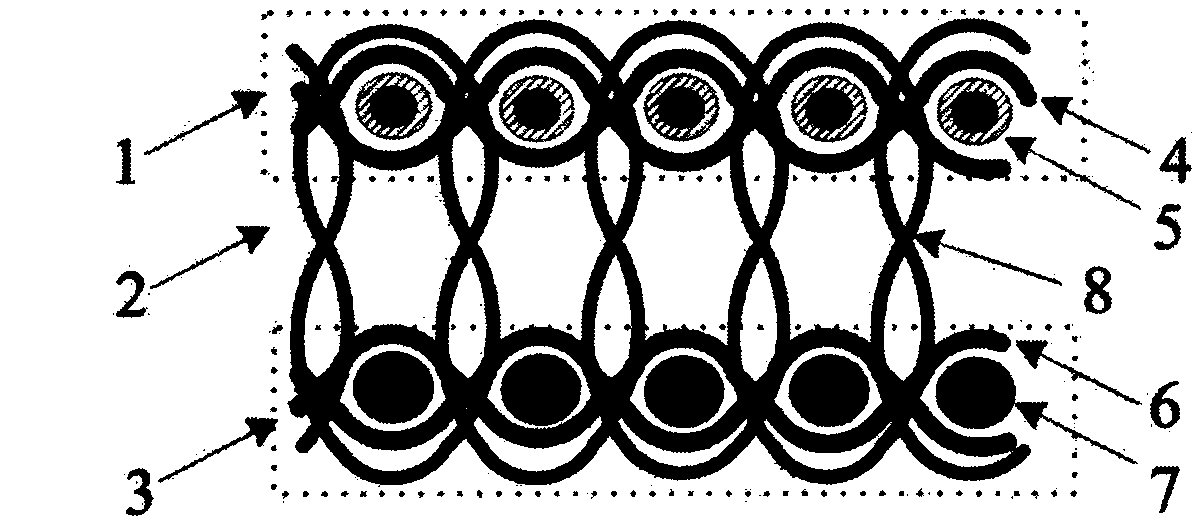

[0031] A three-dimensional interval structure electric heating fabric based on copper wire and its preparation method:

[0032] 1. Yarn selection

[0033] Select the basalt fiber of 800tex (Shijin Basalt Fiber Co., Ltd.) as the warp yarn 4 of the electric heating layer; select the copper tow with a diameter of 1 mm as the weft yarn 5 of the electric heating layer; select the basalt fiber of 1000tex as the warp yarn 6 of the support layer and the weft yarn 7 of the support layer; Select 1000tex glass fiber as the spacer yarn 8; adopt the three-dimensional weaving process, set the width of the fabric to 10 cm; warp and weft density: 5 threads / cm; density of the spacer thread 8: 5 threads / cm.

[0034] 2. Weaving process

[0035] The first step: arrange each layer of warp yarns and spacer yarns 8 according to the yarn selection scheme;

[0036] The second step: synchronously introduce each layer of weft yarn;

[0037] The third step: each layer of warp interweaves;

[0038] St...

Embodiment 2

[0043] A three-dimensional spacer structure electrothermal composite material based on copper wire and its preparation method:

[0044] The electrothermal fabric with three-dimensional spacer structure obtained in Example 1 was used to compound it with epoxy resin to prepare a three-dimensional spacer structure electrothermal composite material based on copper wire.

[0045] Epoxy resin (Guangzhou Hengyue Chemical Co., Ltd., brand: E-51) and curing agent are made into 1000 ml of epoxy resin solution according to the volume ratio of 4:1; After welding, use the hand lay-up process to compound the fabric with epoxy resin, put it in an oven, adjust the temperature to 45°C and dry it for 4 hours; then raise the temperature to 70°C and dry it for 4 hours.

[0046] The obtained copper wire-based three-dimensional space-filling structure electrothermal composite material has a length of 20 cm and a thickness of 0.7 cm. The electrothermal composite material has a density of 1.1kg / cm ...

Embodiment 3

[0048] A three-dimensional spacer structure electric heating fabric based on glass fiber wrapped copper wire and its preparation method:

[0049] 1. Yarn selection

[0050] Choose 1000tex non-alkali glass fiber (Jushi Group) as the heating layer warp yarn 4; choose 300tex glass fiber wrapped copper stranded wire with a diameter of 1 mm as the heating layer weft yarn 5, wrapping parameters: feeding speed ratio 1.5:1; choose 1000tex glass fiber bulked yarn is used as support layer warp yarn 6, support layer weft yarn 7 and spacer yarn 8; adopt three-dimensional weaving weaving process, set the width of the fabric to 10 cm; warp and weft density: 5 pieces / cm; density of spacer yarn 8: 5 roots / cm.

[0051] 2. Weaving process

[0052] The first step: arrange each layer of warp yarns and spacer yarns 8 according to the yarn selection scheme;

[0053] The second step: synchronously introduce each layer of weft yarn;

[0054] The third step: each layer of warp interweaves;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com