Concrete composite column

A technology of concrete and composite columns, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of poor seismic performance, insufficient strength and ductility, and low residual bearing capacity of buildings, so as to achieve good seismic performance and ductility and long service life The effect of improving the length and bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

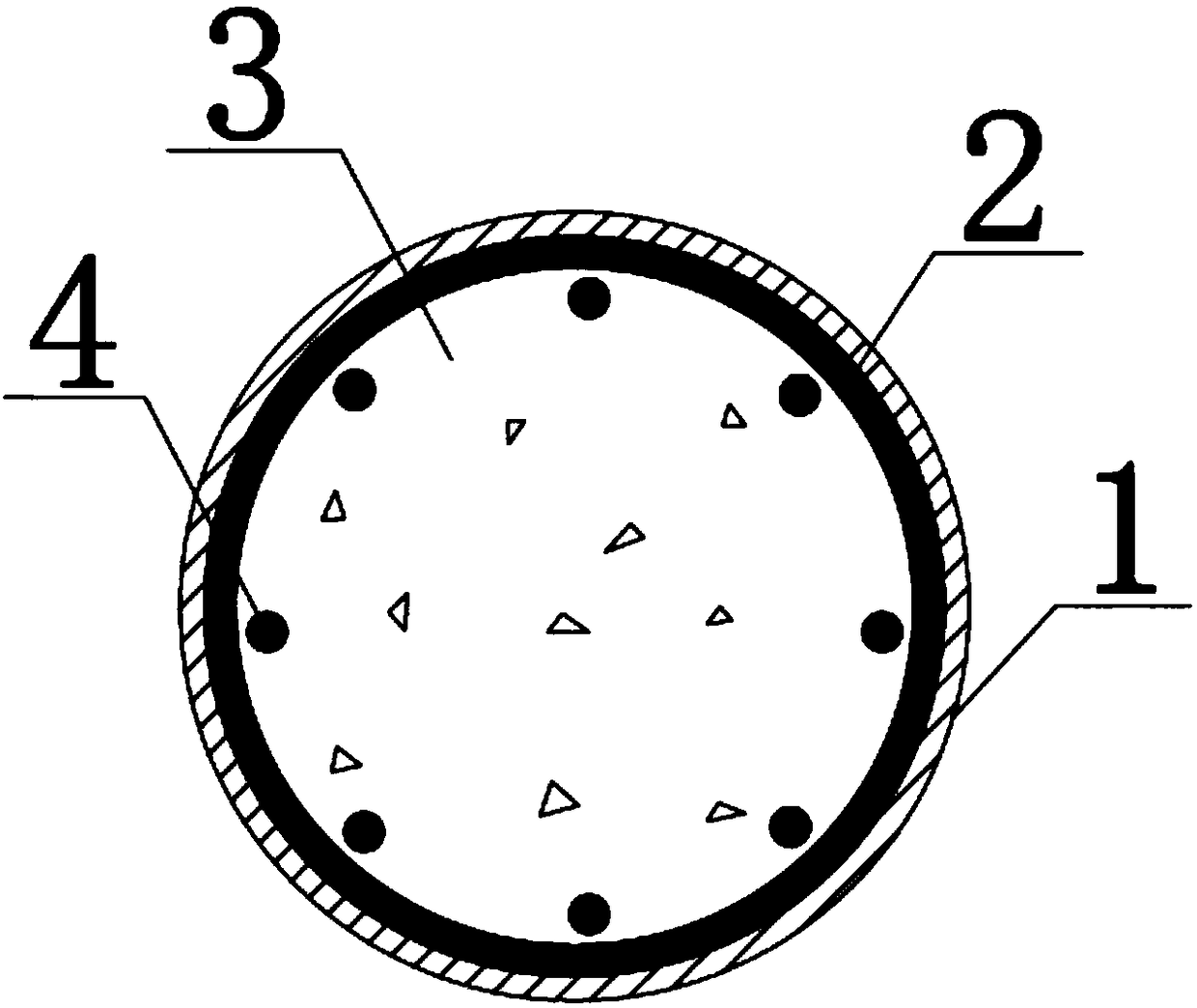

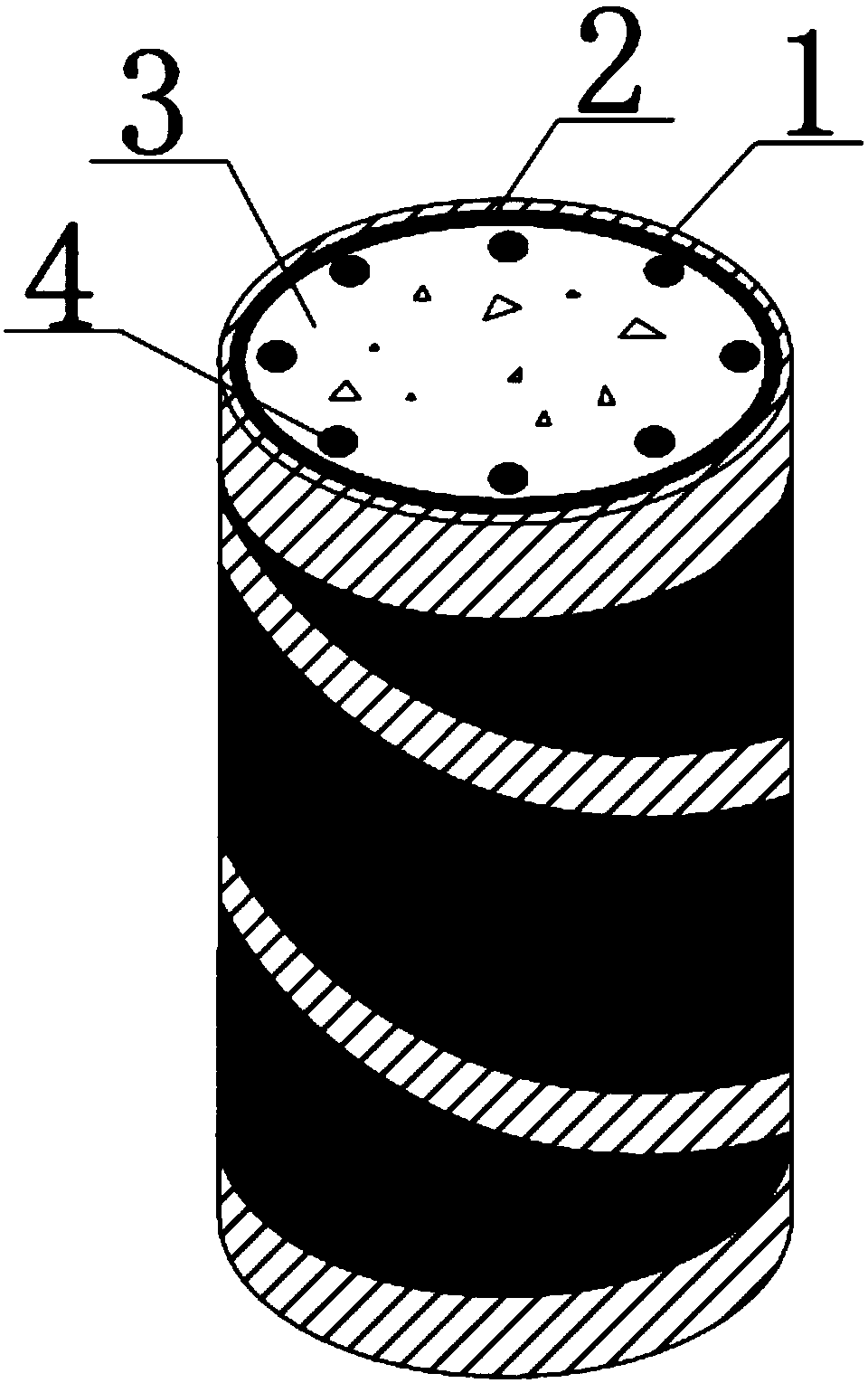

[0028] Such as figure 1 and figure 2 As shown, the concrete composite column of this embodiment includes: a main body 2, a first reinforced structural unit 1 and several second reinforced structural units 4, the first reinforced structural unit 1 is arranged on the outside of the main body 2; the main body 2 is a hollow structure , which is hollow and poured with building materials 3, a number of second reinforced structural units 4 are arranged in the hollow structure inside the body 2, and are fixedly connected with the concrete material; the body 2 is a high-density polyethylene material (HDPE) component; the first The reinforced structural unit 1 is a fiber reinforced composite (FRP) component.

[0029] In this embodiment, the first reinforcing structure unit 1 is selected as a strip-shaped FRP strip, which wraps around the outer surface of the HDPE main body 2 in a spiral shape.

[0030] In this embodiment, the second reinforced structural unit 4 is a fiber-reinforced ...

Embodiment 2

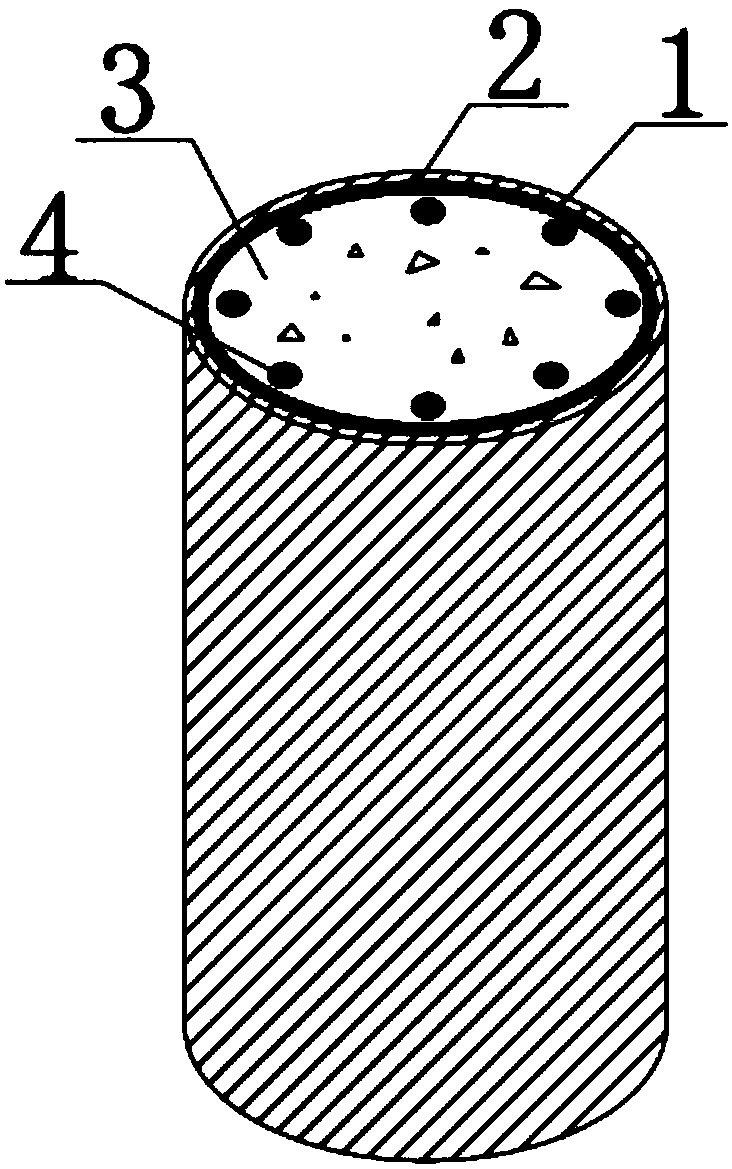

[0039] Such as image 3 As shown, the first reinforcing structural unit 1 of this embodiment is selected as a sheet-like FRP strip, which is fully covered on the outer surface of the HDPE body 2 .

[0040] The rest are basically the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0042] Such as Figure 4 As shown, the concrete composite column of this embodiment does not include the second reinforced structural unit. The rest are basically the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com