Method for testing content of alkyl chloride aluminum for ethylene-propylene polymerization

A technology of alkylaluminum chloride and ethylene propylene, which is applied in the field of ethylene-propylene rubber, can solve problems such as inconvenient operation, inaccurate testing, and rough hydrolysis treatment and absorption methods, and achieve the effect of simple and easy method and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0057] (1) Hydrolysis treatment:

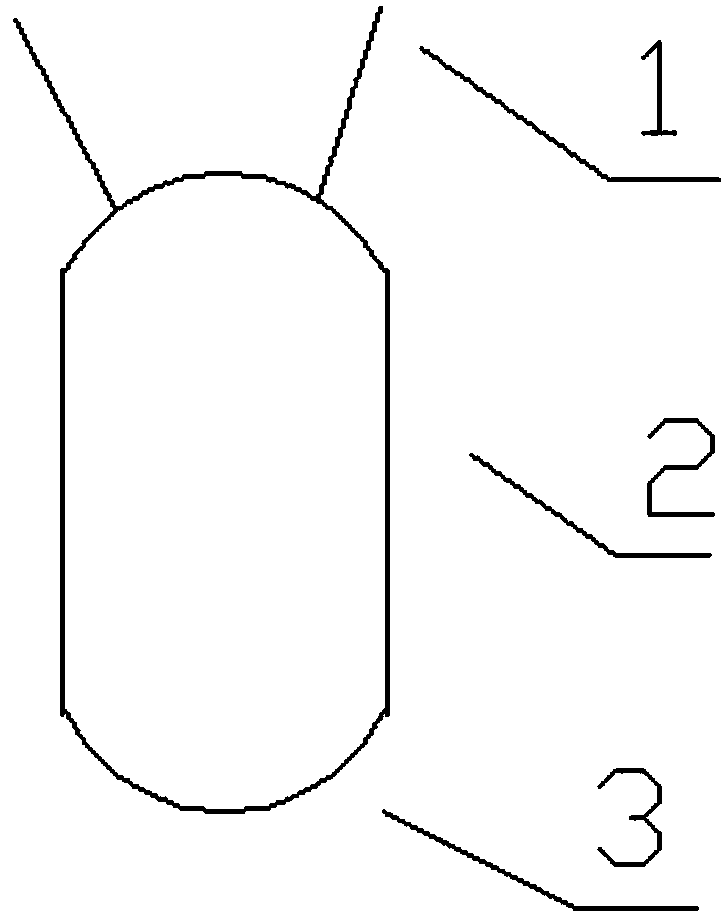

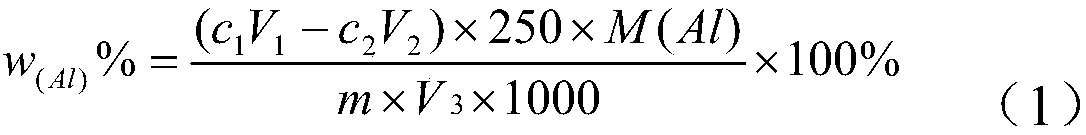

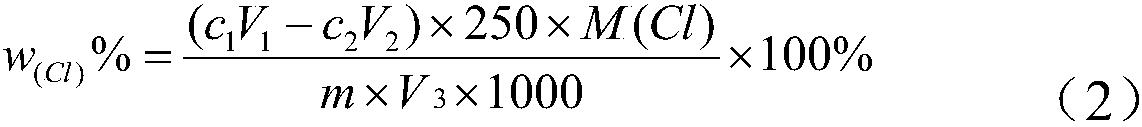

[0058] Replace the dried vessel 1 with nitrogen gas, connect the glass tubes on both sides to the latex tubes, clamp them with water-stop clamps, add 30mL of anhydrous ether, and weigh to an accuracy of 0.0002g. Use a 5-10mL glass syringe to add 2-10mL of the alkylaluminum chloride sample to be tested from one side of the latex tube, weigh to an accuracy of 0.0002g, and the difference between the two weights is the sample weight.

[0059] Connect the latex tube on one side of the container 1 to the water washing device, that is, two water washing bottles connected in series. Slowly add 5-15mL of 5-15% sulfuric acid from the unconnected side. Do not generate a lot of air bubbles during this process. After the hydrolysis reaction is complete, transfer all the liquid to a 250mL volumetric flask, and rinse the absorption bottle and vessel 1 with water. Pour into a volumetric flask. After fully shaking, stand still for 5 minutes, and finally use...

Embodiment 1

[0097] Hydrolysis treatment:

[0098] Replace the dried 50mL container 1 with nitrogen, connect the glass tubes on both sides to the latex tubes, clamp them with water-stop clips, add 30mL of anhydrous ether, and weigh them, and the weight is 91.3308g. Use a 10mL glass syringe to add 4mL of ethylaluminum sesquichloride to be tested from one side of the latex tube, weigh it, the weight is 94.3808g, and the difference between the two weights is the sample weight is 3.0500g.

[0099] Connect the latex tube on one side of the container 1 to the water washing device, that is, two water washing bottles connected in series. Slowly add 10mL of 8% sulfuric acid from the unconnected side, bubbles appear slowly, the hydrolysis reaction is complete, and no bubbles appear, transfer all the liquid to a 250mL volumetric flask, rinse the absorption bottle and vessel 1 with water, and pour all the rinse water into the volumetric flask bottle. After fully shaking, stand still for 5 minutes, a...

Embodiment 2

[0107] Hydrolysis treatment:

[0108] Replace the dried 50mL vessel 1 with nitrogen gas, connect the glass tubes on both sides to the latex tubes, clamp them with water-stop clamps, add 30mL of anhydrous ether, weigh, and the weight is 88.2289g. Use a 5mL glass syringe to add 2mL of ethylaluminum sesquichloride to be tested from one side of the latex tube, weigh it, the weight is 89.6309g, the difference between the two weights is the sample weight is 1.402g.

[0109] Connect the latex tube on one side of the container 1 to the water washing device, that is, two water washing bottles connected in series. Slowly add 15mL of 10% sulfuric acid from the unconnected side, bubbles appear slowly, the hydrolysis reaction is complete, and no bubbles appear, transfer all the liquid to a 250 volumetric flask, rinse the absorption bottle and vessel 1 with water, and pour all the rinse water into the volumetric flask bottle. After fully shaking, stand still for 5 minutes, and finally use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com