Graphene-polyaniline composite heavy-duty anti-corrosion coating and preparation method thereof

A graphene and polyaniline technology, applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of low utilization rate, waste, pollution, etc. of zinc, improve utilization rate, simple preparation method, and meet performance indicators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of graphene-polyaniline composite heavy-duty anti-corrosion coating:

[0043] Take 0.1g of graphene and 0.1g of sodium dodecylbenzene sulfonate in 200mL of pure water for 2 hours, filter, and dry at 70°C;

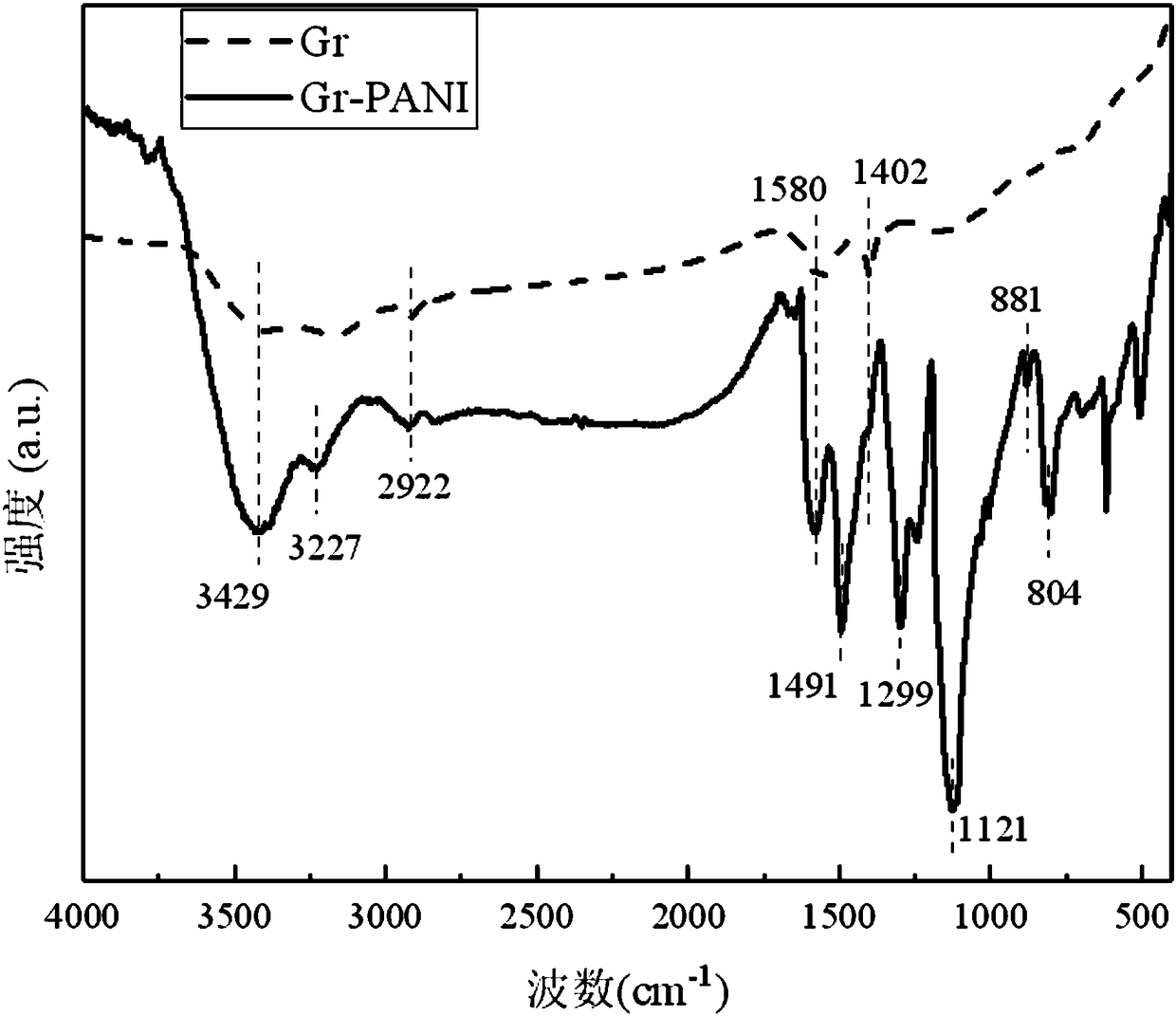

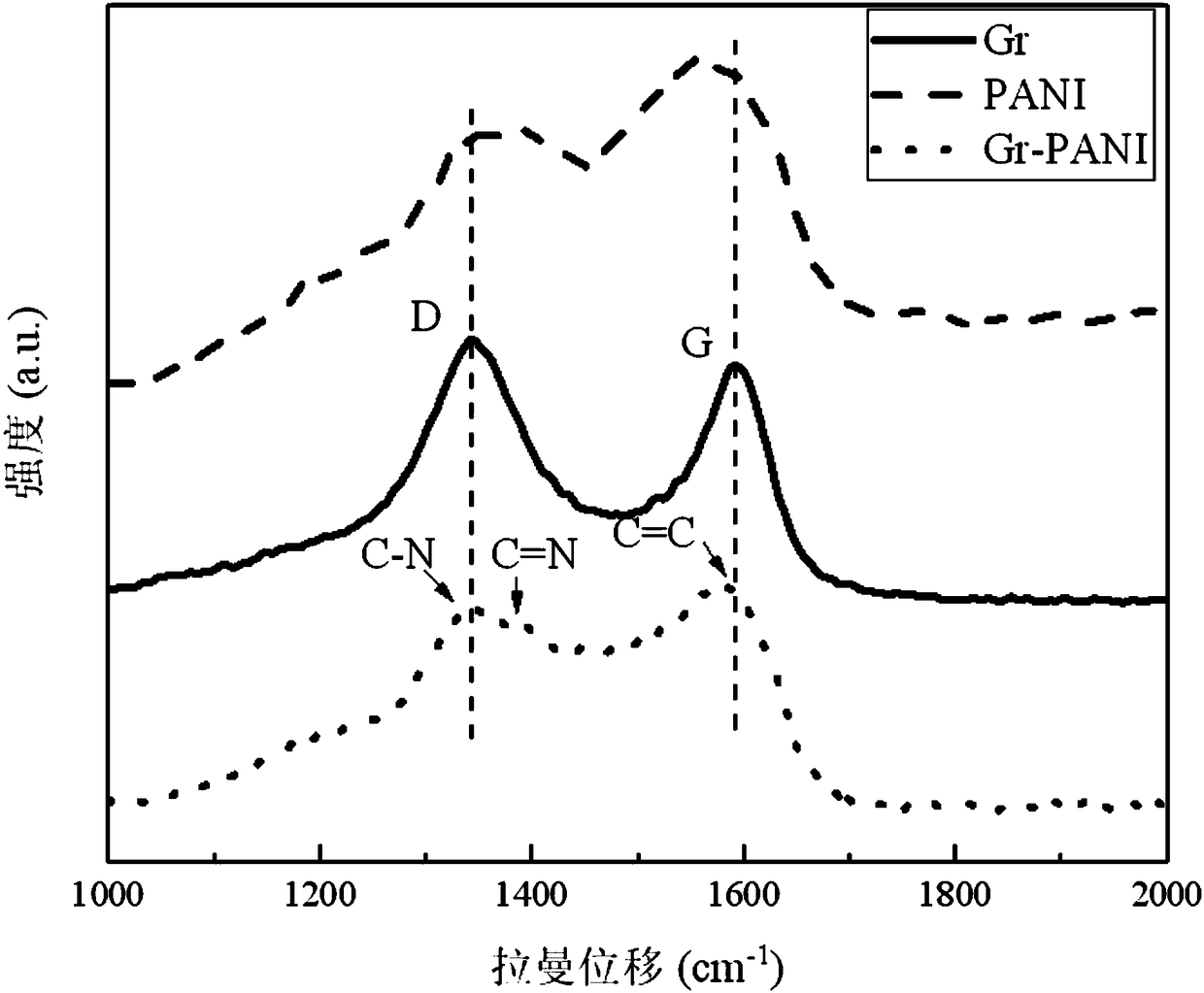

[0044] After drying, add 0.5mL aniline and 25mL hydrochloric acid and stir at 5°C for 1h, add 0.6g ammonium persulfate, stir at 5°C for 24h, filter the solution with suction, wash, and dry to obtain graphene-polyaniline;

[0045] Take 0.0075g of the above-prepared graphene-polyaniline, add 1.5mL xylene and perform ultrasonication for 30min, take it out for later use; take 4g of epoxy resin and 1g of curing agent, stir well, pour the ultrasonicated graphene-polyaniline- Toluene solution, continue to stir evenly; add 4g of zinc powder, then fully stir, let it stand for 2min, apply the slurry on a 10×10×1mm iron block (polish the surface of the iron block smooth with 800# sandpaper), let it dry naturally for 48h, Finish the preparation.

[0046] S...

Embodiment 2

[0051] A preparation method of graphene-polyaniline composite heavy-duty anti-corrosion coating:

[0052] Take 0.1g of graphene and 0.1g of sodium dodecylbenzene sulfonate in 200mL of pure water for 2 hours, filter, and dry at 70°C;

[0053] After drying, add 0.5mL aniline and 25mL hydrochloric acid and stir at 5°C for 1h, add 0.6g ammonium persulfate, stir at 5°C for 24h, filter the solution with suction, wash, and dry to obtain graphene-polyaniline;

[0054] Take 0.015g of the above-prepared graphene-polyaniline, add 1.5mL of xylene and perform ultrasonication for 30min, take it out for later use; take 4g of epoxy resin and 1g of curing agent, stir well, pour in the ultrasonicated solution, and continue to stir evenly; add 4g of zinc powder, then fully stirred, let it stand for 2 minutes, and coated the coating on a 10×10×1mm iron block (the surface of the iron block was smoothed with 800# sandpaper), and dried naturally for 48 hours to complete the preparation.

[0055] Su...

Embodiment 3

[0057] A preparation method of graphene-polyaniline composite heavy-duty anti-corrosion coating:

[0058] Take 0.1g of graphene and 0.1g of sodium dodecylbenzene sulfonate in 200mL of pure water for 2 hours, filter, and dry at 70°C;

[0059] After drying, add 0.5mL aniline and 25mL hydrochloric acid and stir at 5°C for 1h, add 0.6g ammonium persulfate, and stir at 5°C for 24h. The solution is suction filtered, washed and dried;

[0060] Take 0.03g of graphene-polyaniline, add 2mL of xylene for ultrasonication for 30min, take it out for later use; take 4g of epoxy resin and 1g of curing agent, stir well, pour in the ultrasonicated solution, and continue stirring evenly; add 4g of zinc powder, Stir fully again, let it stand for 2 minutes, apply the coating on a 10×10×1mm iron block (the surface of the iron block is smoothed with 800# sandpaper), let it dry naturally for 48 hours, and complete the preparation.

[0061] Such as Figure 4 Shown, be the electrochemical impedance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com