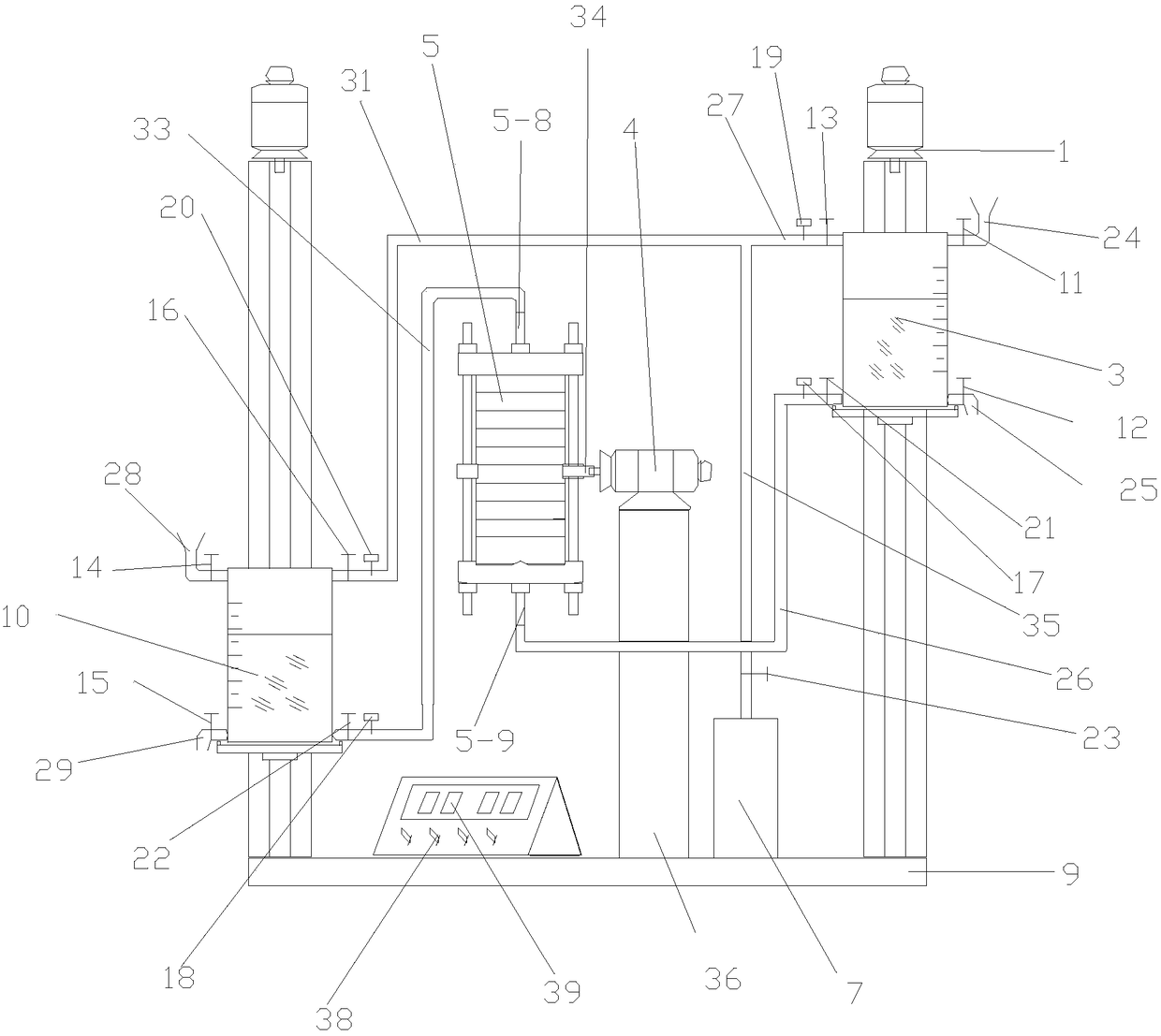

Reciprocating leaching experimental device and experimental method

An experimental device, reciprocating technology, applied in measurement devices, material inspection products, suspension and porous material analysis, etc., can solve problems such as poor reproducibility, large consumption of leachate, and inability to simulate complex geological conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

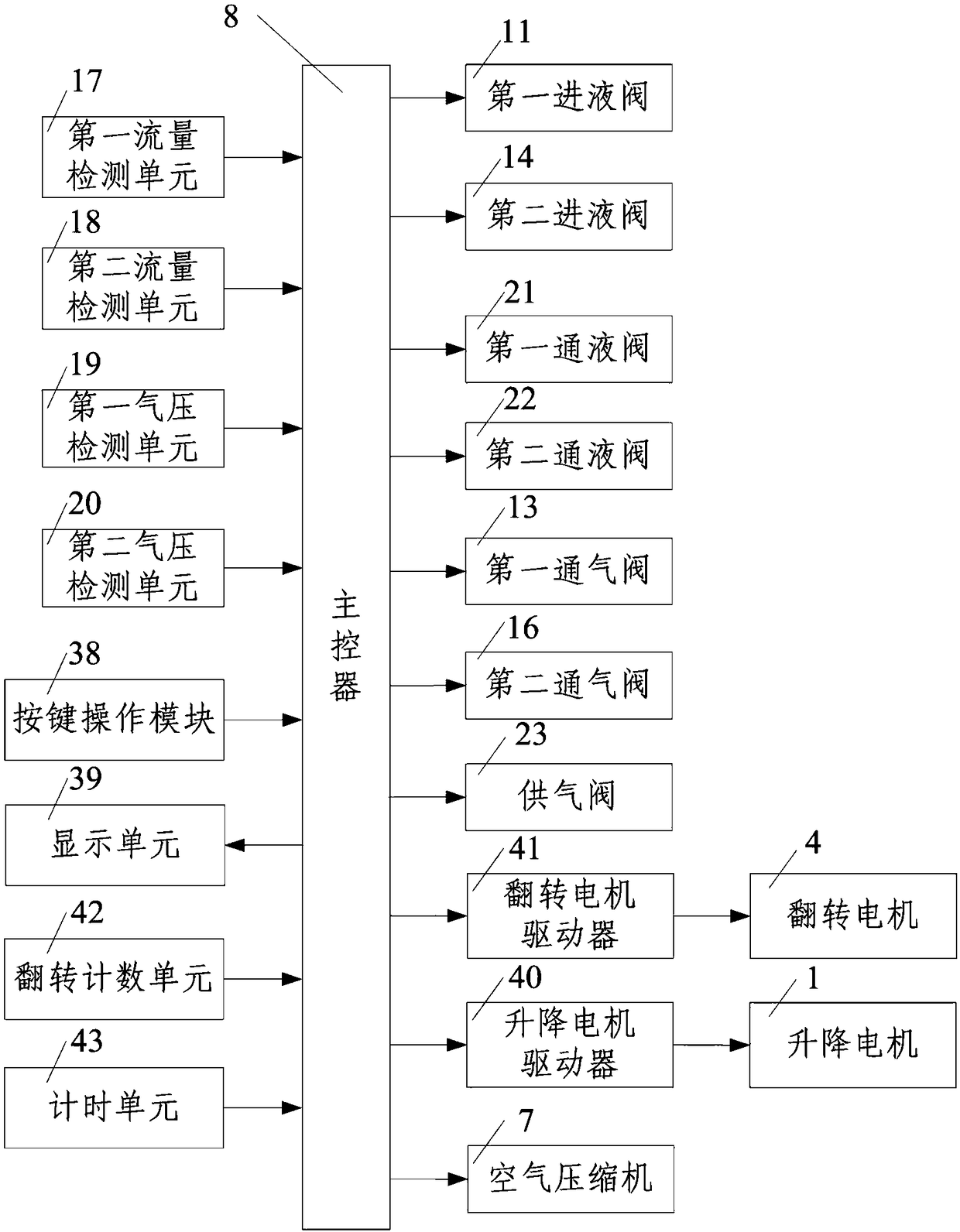

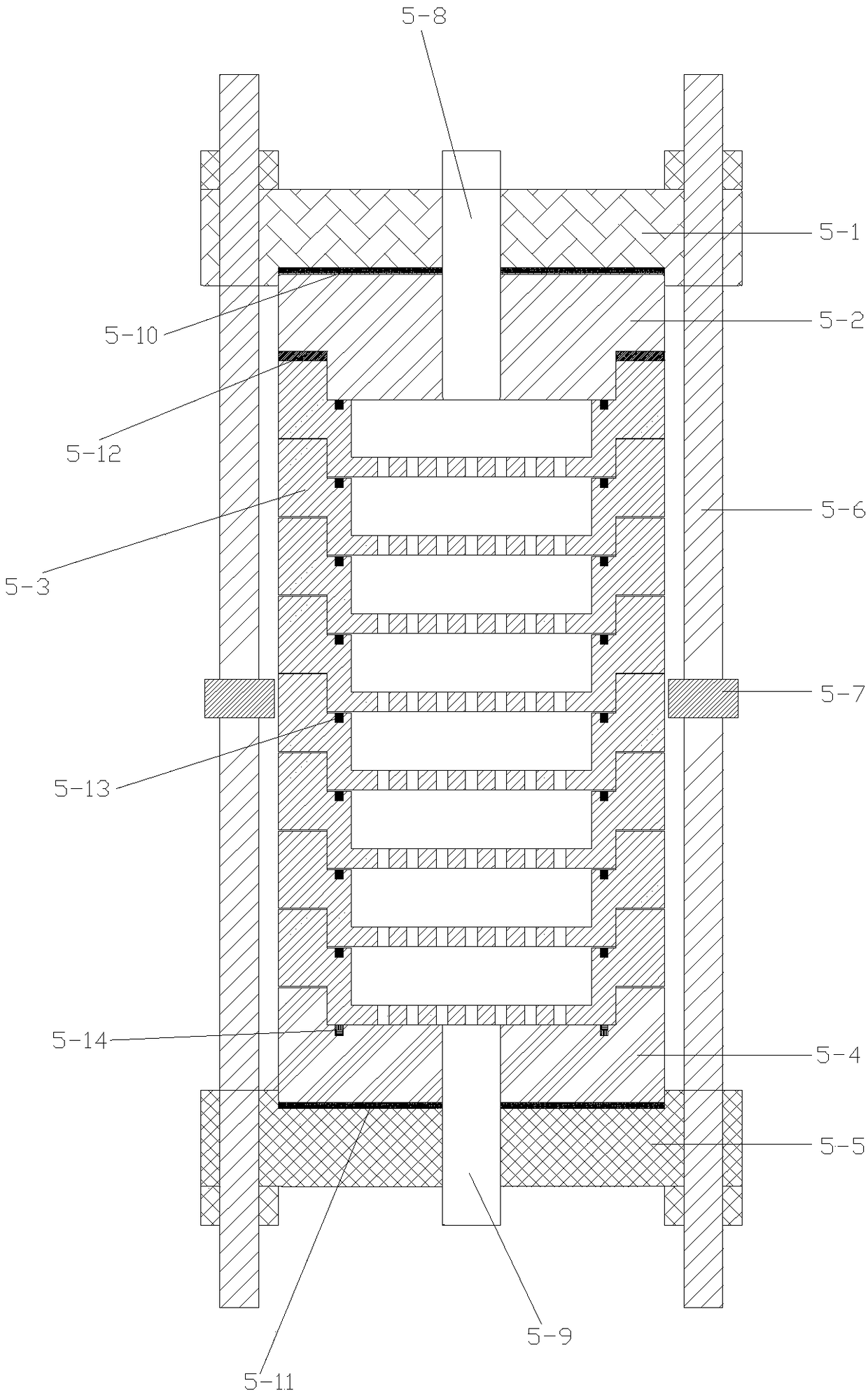

Method used

Image

Examples

Embodiment 2

[0146] This embodiment includes the following steps:

[0147] Step 1, equipment before leaching experiment, the specific process is as follows:

[0148] Step 101, preparation of samples for leaching experiments: using crushing equipment to crush a plurality of different media to be leached to obtain a plurality of samples for leaching experiments; wherein, the particle size of the samples for leaching experiments is not greater than 80 mesh;

[0149] In this embodiment, the particle size of the leaching test sample is not greater than 80 meshes, because the leaching test simulates the leaching process of the geological body, so the leaching test sample should conform to the porosity of the simulated geological body, The leachate can pass through the leaching test sample, and ensure that the leaching test sample is fully in contact with the forest filtrate, so that the leaching test can be carried out normally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com