Composition, preparation method and application of a kind of olefin polymerization catalyst carrier

A reaction, hydrocarbon-based technology, applied in the field of spherical alkoxy magnesium particles, can solve the problems of high cost, low bulk density, uneven large particles or fine powder, etc., to reduce production costs, good particle sphericity, compose simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

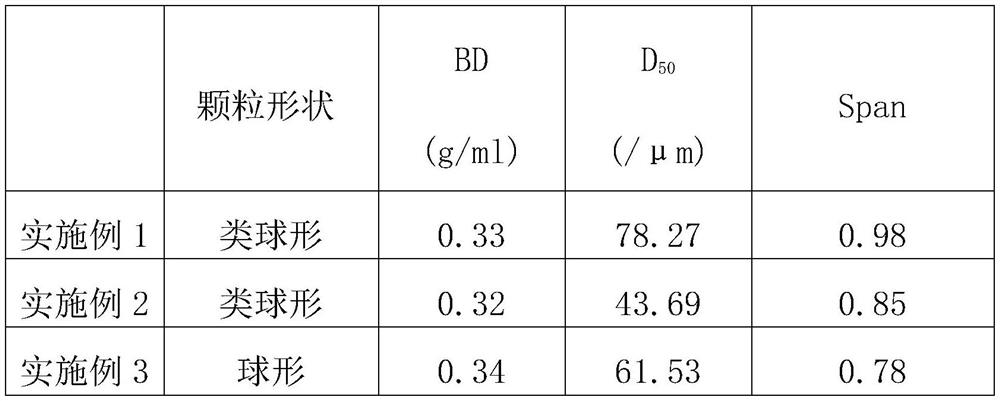

Embodiment 1

[0031] Fully replace the reactor with high-purity nitrogen, add 0.20 g of anhydrous magnesium carboxylate, 25 ml of absolute ethanol and 0.15 g of iodine in turn under the protection of nitrogen, stir and dissolve, then heat up, add 1.0 g and 10 ml of 80-150 mesh magnesium powder Absolute ethanol, maintain the reflux reaction, add 1.0 g of 80-150 mesh magnesium powder and 10 ml of absolute ethanol again at intervals of 20 minutes, add 4.0 g of magnesium powder and 65 ml of absolute ethanol in 4 times, and maintain reflux after adding the materials React for 3 hours, then wash twice with absolute ethanol, each time the amount of absolute ethanol is 80 ml, then wash twice with hexane, each time the amount of hexane is 100 ml, after washing, dry to obtain off-white solid Flowable powder, the specific results are shown in Table 1.

Embodiment 2

[0033] The only difference between this example and Example 1 is that in Example 1, "25 milliliters of absolute ethanol" is adjusted to "40 milliliters of absolute ethanol", and "80-150 mesh magnesium powder" is adjusted to "100-200 mesh Magnesium powder".

Embodiment 3

[0035] The difference between this embodiment and Example 1 is only that "0.20 grams of anhydrous magnesium carboxylate" in Example 1 is adjusted to "0.50 grams of anhydrous magnesium carboxylate".

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com