Polymer plastic material and manufacturing method thereof

A technology of a plastic material and a manufacturing method, applied in the field of polymer plastic materials and its manufacturing, can solve the problems of poor plastic deformation resistance, inability to achieve both, and low compression recovery ability, and achieve good compression recovery ability and high deformation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

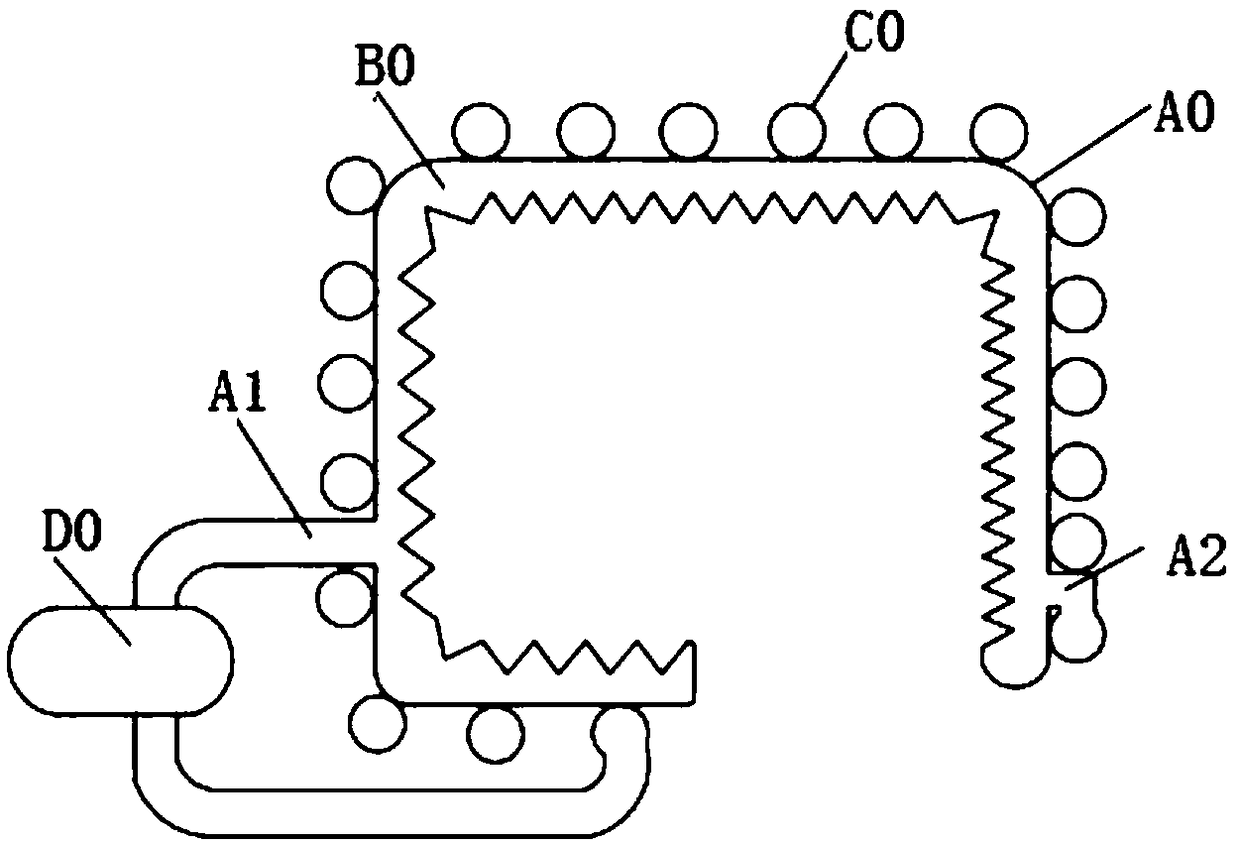

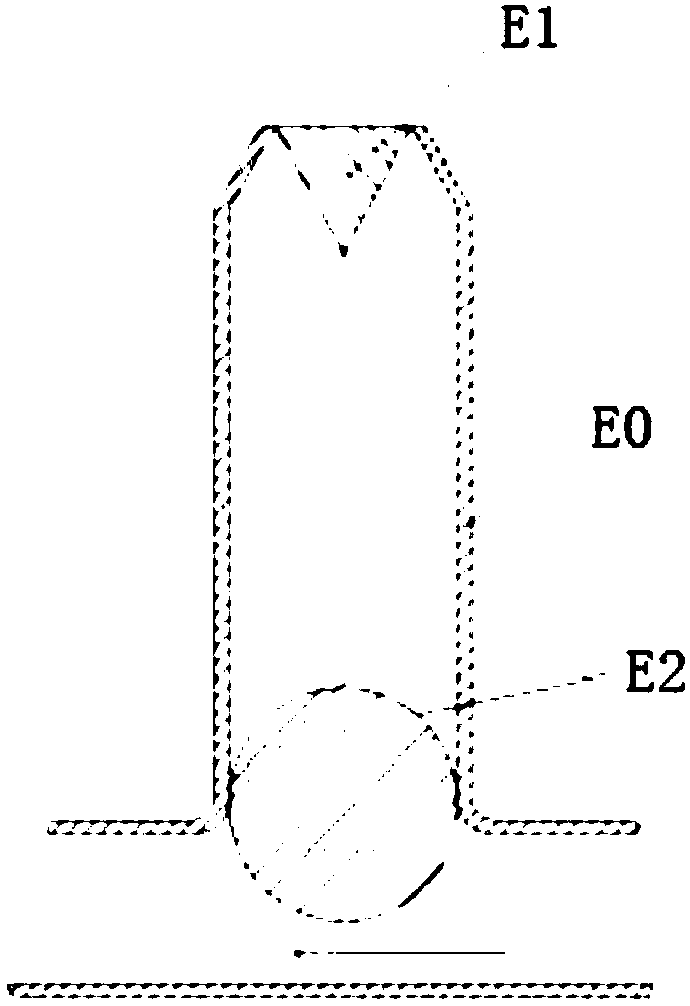

[0035] like Figure 1-Figure 2 Shown, polymer plastic material, it comprises the following components in parts by weight: parts by weight is the polyamide of 150 parts; The limestone one that parts by weight is 22 parts; Disilazane; parts by weight are 0.06 parts of polyethylene wax; parts by weight are 14-42 parts of titanium dioxide; parts by weight are 4 parts of limestone two; parts by weight are 2 parts of titanium dioxide; parts by weight 0.05 parts of dibutyltin dilaurate solution; 3 parts by weight of polyimide; and 3.6 parts by weight of reinforcing agent DH-2. In this way, the polymer plastic material not only has good compression recovery ability and high deformation resistance, but also can meet the specific needs of some components.

[0036] The relative molecular mass of the polyamide is 2500. In this way, the compression recovery ability and high deformation resistance of the plastic can be improved.

[0037] The diameter of the powder particles of the titani...

Embodiment 2

[0067] like Figure 1-Figure 2 Shown, polymer plastic material, it comprises the following components by weight part: weight part is the polyamide of 150 parts; Weight part is the limestone one of 38 parts; Weight part is the hexamethyl Disilazane; parts by weight are 0.09 parts of polyethylene wax; parts by weight are 28 parts of titanium dioxide; parts by weight are 8 parts of limestone two; parts by weight are 4 titanium dioxide; parts by weight are 0.45 parts dibutyltin dilaurate solution; 5 parts by weight of polyimide; and 3.6 parts by weight of reinforcing agent DH-2. In this way, the plastic not only has good compression recovery ability and high deformation resistance, but also can meet the specific needs of some components.

[0068] The relative molecular mass of the polyamide is 2750. In this way, the compression recovery ability and high deformation resistance of the plastic can be improved.

[0069] The diameter of the powder particles of the titanium dioxide i...

Embodiment 3

[0099] like Figure 1-Figure 2 Shown, polymer plastic material, it comprises the following component by weight part: weight part is the polyamide of 150 parts; Weight part is the limestone one of 54 parts; Weight part is the hexamethyl Disilazane; parts by weight are 0.12 parts of polyethylene wax; parts by weight are 42 parts of titanium dioxide; parts by weight are 12 parts of limestone two; parts by weight are 6 parts of titanium dioxide; parts by weight are 0.85 parts dibutyltin dilaurate solution; 7 parts by weight of polyimide; and 3.6 parts by weight of reinforcing agent DH-2. In this way, the plastic not only has good compression recovery ability and high deformation resistance, but also can meet the specific needs of some components.

[0100] The relative molecular mass of the polyamide is 3200. In this way, the compression recovery ability and high deformation resistance of the plastic can be improved.

[0101] The diameter of the powder particles of the titanium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com