Acetoin high-yield strain and application thereof in fermentation to produce acetoin

A technology of acetoin and bacilli, applied in the field of bioengineering, can solve the problems of low yield of target products, inability to be widely popularized, shortage of raw materials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

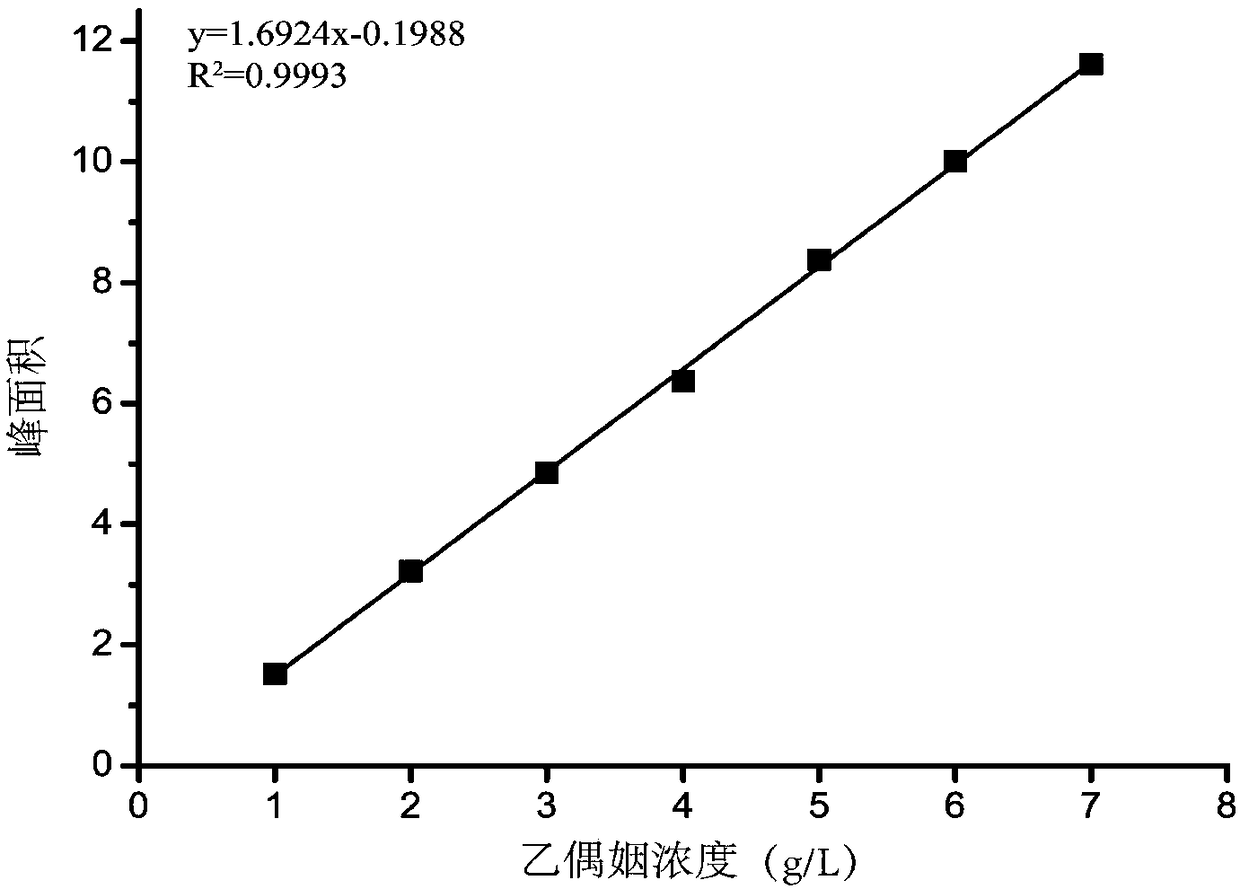

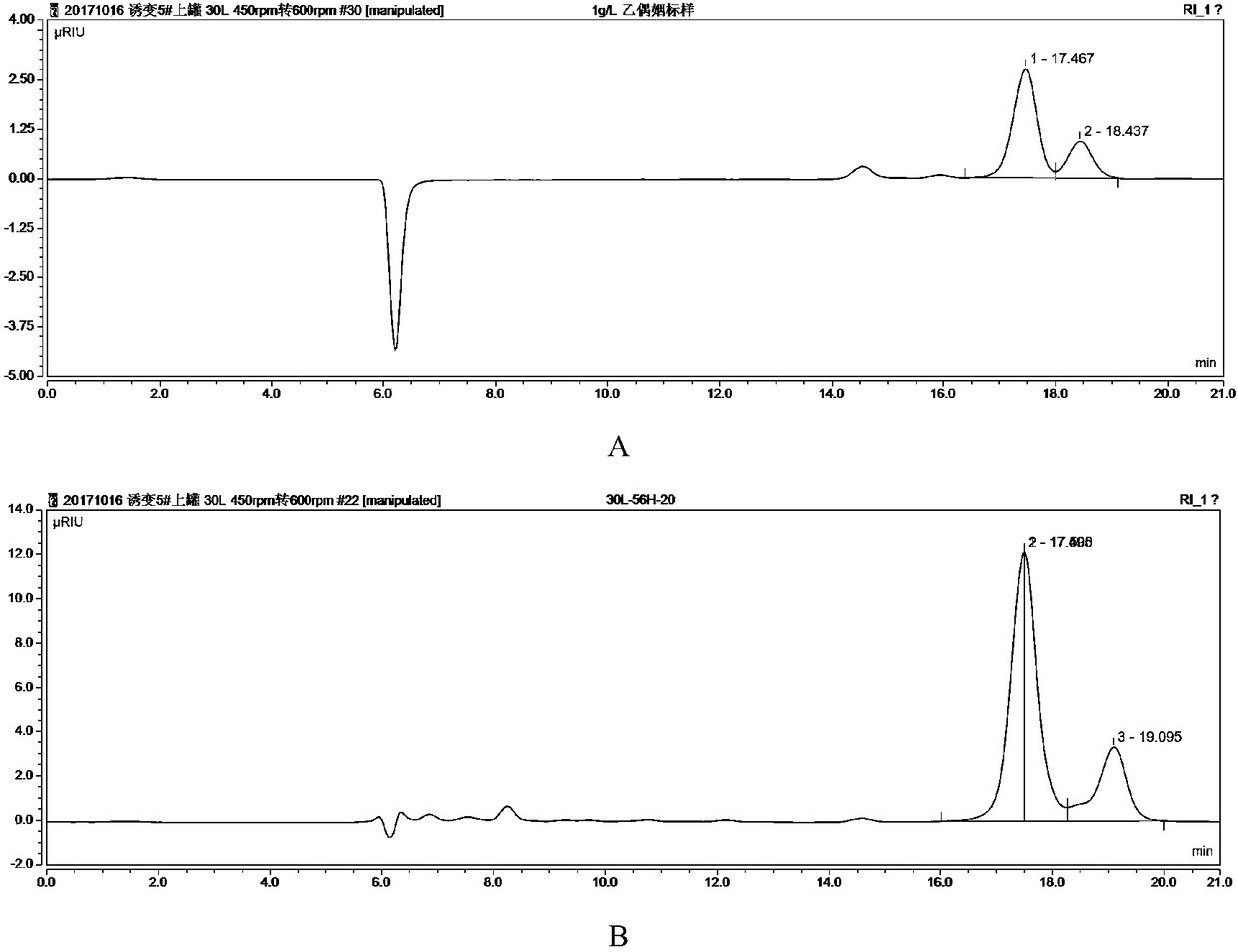

Method used

Image

Examples

Embodiment 1

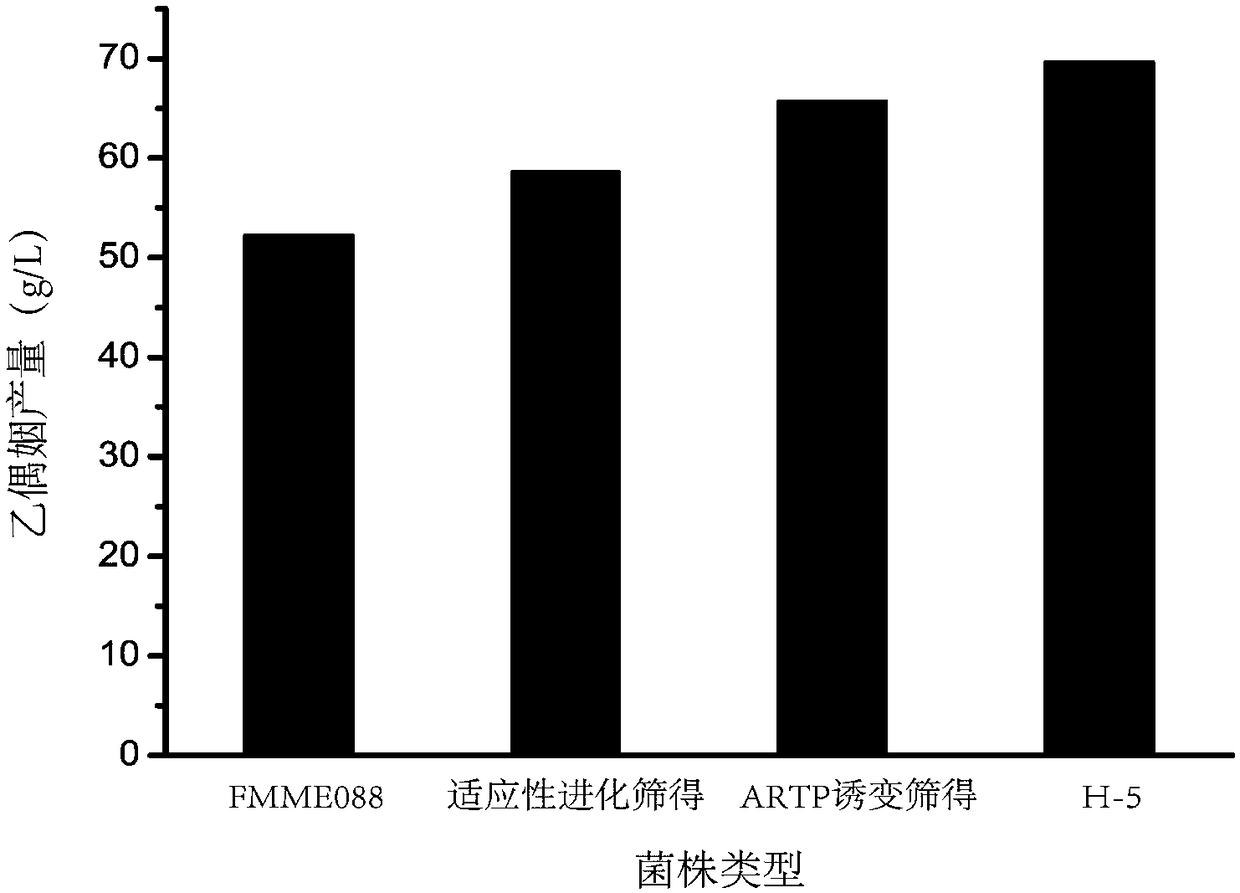

[0026] (1) Adaptive evolution:

[0027] A. Take 200 μL of the original bacterial strain Bacillus amyloliquefaciens FMME088 and insert it into a 500mL shaker flask containing 50mL of seed medium. After cultivating at 200rpm for 12 hours at 37°C, insert it into 500mL of 50mL screening liquid medium (the concentration of acetoin is 70g / L). After culturing in a shake flask at 37°C and 200rpm for 24 hours, the bacterial solution was centrifuged at 4°C and 6000rpm for 5 minutes, and all the obtained bacteria were transferred to the screening liquid medium with acetoin concentration of 70g / L for 3 times, and then the third time was taken. After culturing for 24 hours, centrifuge at 4°C, 6000rpm for 5min, and transfer all the obtained bacteria into a 500mL shake flask containing 50mL screening liquid medium (the concentration of acetoin is 80g / L), and repeat the transfer of acetoin The screening liquid medium with a concentration of 80g / L was used for 3 times. Repeat this operation, ...

Embodiment 2

[0046] The screened bacterial strains were identified according to "Microbial Taxonomy" for their physiological and biochemical characteristics (see Tables 1 and 2 below):

[0047] Table 1 Comparison of colony morphological characteristics

[0048]

[0049] Table 2 Physiological and biochemical identification results of strains

[0050]

Embodiment 3

[0051] Example 3: Detection of acetoin tolerance of mutant strains

[0052] Step 1: Prepare medium

[0053] Seed medium in g / L: glucose 60, yeast powder 10, soybean peptone 10, beef extract 10, NaCl 0.5;

[0054] Acetoin tolerance verification medium in g / L: acetoin (0, 70, 80, 85, 90, 95, 100), glucose 20, yeast powder 12.5, peptone 12.5, KH 2 PO 4 3,K 2 HPO 4 3. MgSO 4 ·7H 2 O 0.4;

[0055] Solid medium in g / L: glucose 20, yeast powder 10, soybean peptone 10, NaCl 5, agar powder 20.

[0056] Step 2: Acetoin Tolerance Test

[0057] Take 0.2mL from the refrigerated glycerol tube and insert it into a 500mL Erlenmeyer flask containing 50mL seed medium, and culture it with shaking at 200rpm at 37°C for 12h. Inoculate seeds into 750 mL shake flasks containing 70 mL of acetoin tolerance verification medium, initial OD 600 =1.5, 37°C, 200rpm shaking culture for 6h, then add acetoin, so that the final concentration of acetoin in the medium is 0, 70, 80, 85, 90, 95 and 100g·...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com