Heating device capable of randomly adjusting heating area of high-strength steel and heating method of heating device

A heating area and heating device technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of long production cycle, easy oxidation of steel heating, and increased operation difficulty, and achieve simple equipment, smooth conversion, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] The invention also discloses a heating method of a high-strength steel thermoforming heating device comprising:

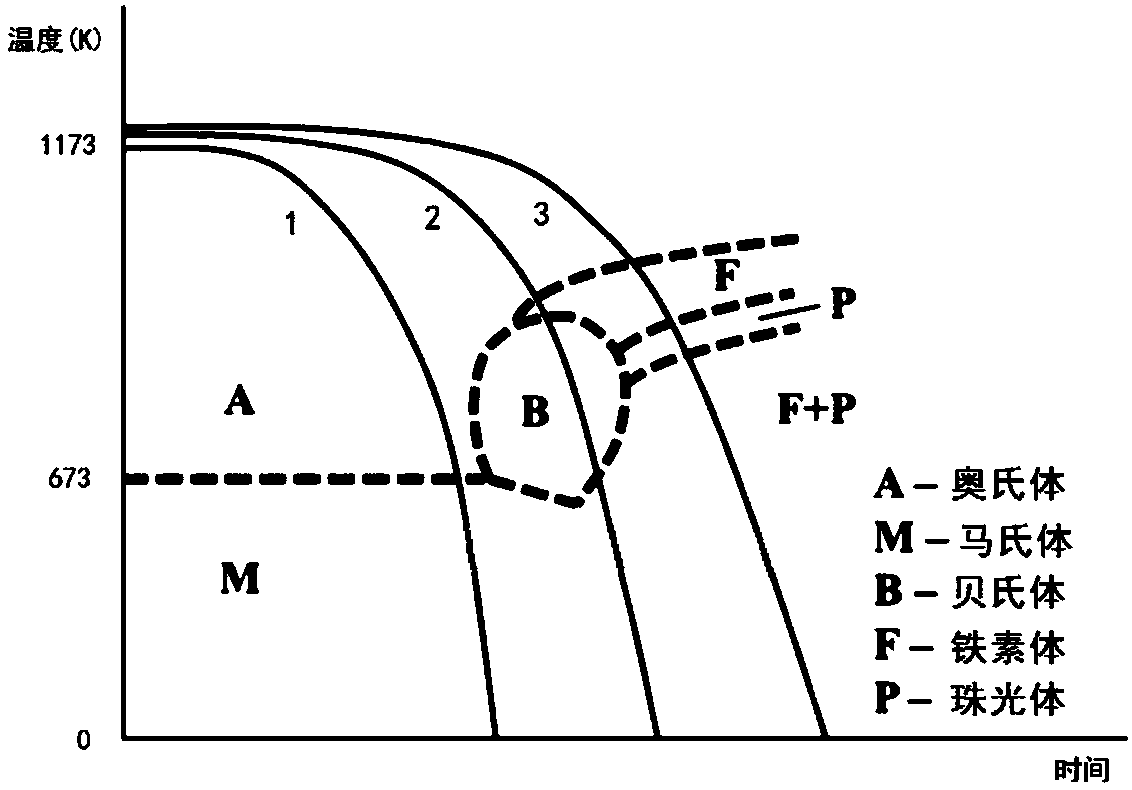

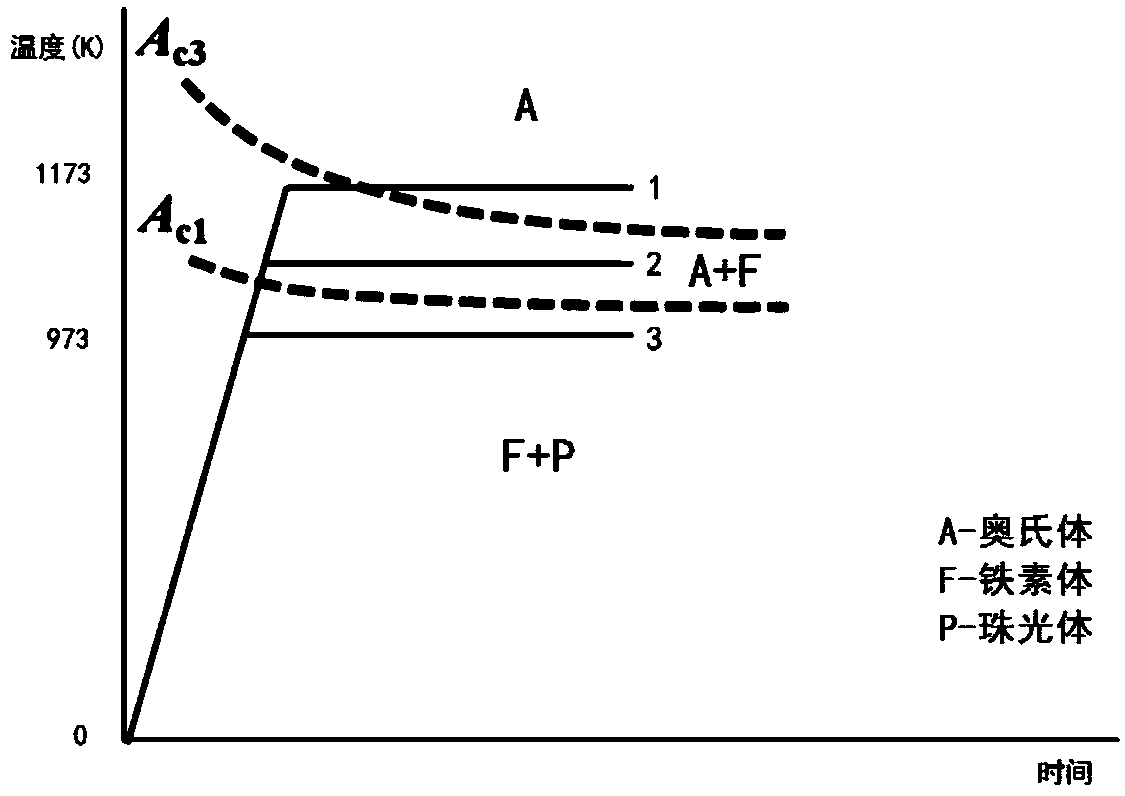

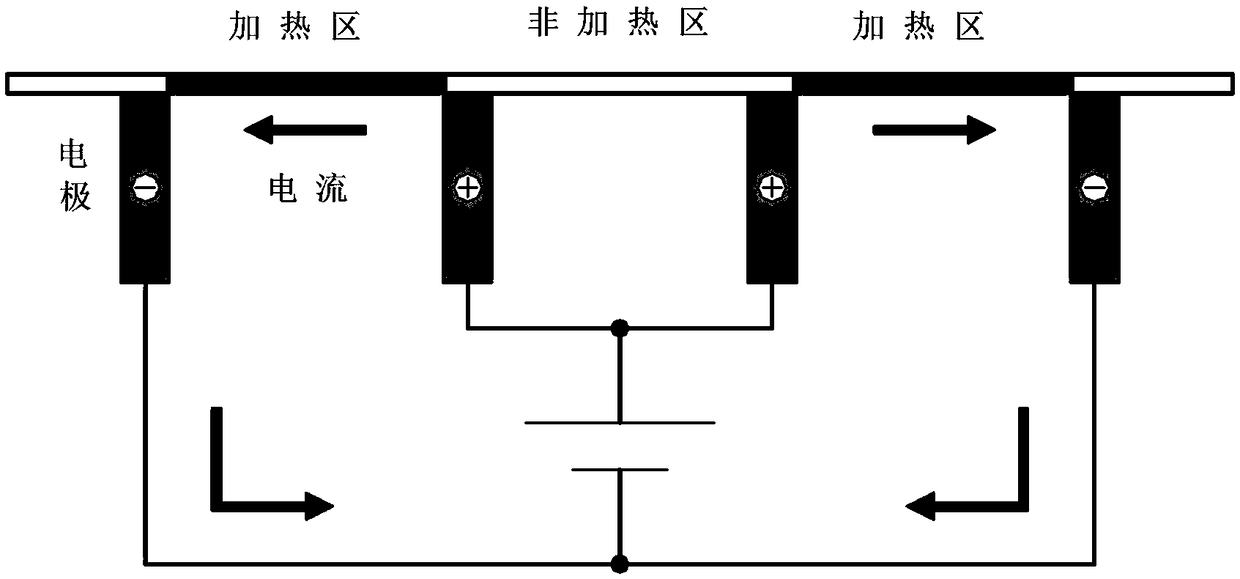

[0093] Such as Figure 5a , Figure 9 , Figure 10 As shown, taking the distance ratio between the first upper fixed electrode 310, the first moving electrode 320, the second moving electrode 330, and the second upper fixed electrode 340 as 1:1:1 as an example, the board can be realized by heating different regions. The middle area of the material is the martensite phase, and the two end areas are the mixed phase of ferrite and pearlite; wherein, a high-strength steel material 500 with a size of 2000mm×800mm×1.5mm and a material of 22MnB5 is used as the operation object.

[0094] Proceed as follows:

[0095] 1. Use a cutting machine to cut a piece of high-strength steel sheet with a size of 2000mm×800mm×1.5mm and a material of 22MnB5;

[0096] 2. The control system controls the upper module to move upward at a speed of 0.2m / s to the maximum position an...

Embodiment 2

[0105] The invention also discloses a heating method of a high-strength steel thermoforming heating device comprising:

[0106] Such as Figure 5a , Figure 9 , Figure 10 As shown, taking the distance ratio between the first upper fixed electrode 310, the first moving electrode 320, the second moving electrode 330, and the second upper fixed electrode 340 as 1:1:1 as an example, the board can be realized by heating different regions. The middle area of the material is the martensite phase, and the two end areas are the mixed phase of ferrite and pearlite; wherein, a high-strength steel material 500 with a size of 2000mm×800mm×1.5mm and a material of 22MnB5 is used as the operation object.

[0107] Proceed as follows:

[0108] 1. Use a cutting machine to cut a piece of high-strength steel sheet with a size of 2000mm×800mm×1.5mm and a material of 22MnB5;

[0109] 2. The control system controls the upper module to move upward at a speed of 0.2m / s to the maximum position an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com