Steel structure surface corrosion prevention process

A steel structure and process technology, applied in metal material coating process, melt spraying, coating and other directions, can solve the problems of high cost, steel structure anti-corrosion ability can not meet the needs of use, impetuous anti-corrosion process operation, etc., to improve the use of Longevity, improved structural strength and wear resistance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

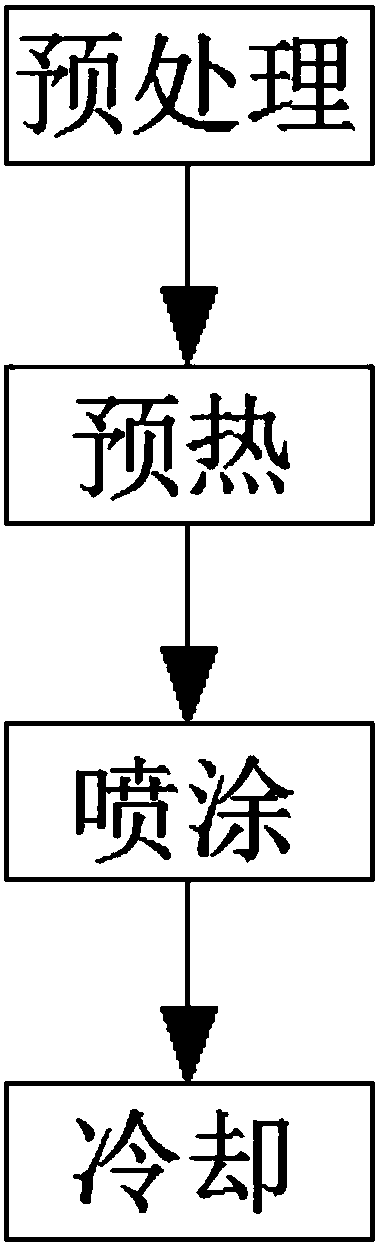

[0020] The steel structure surface anticorrosion process includes the following steps:

[0021] S1: Pretreatment: Clean and derust the surface of the steel structure, and then perform sandblasting roughening with dry, compressed and oil-free air, with a sandblasting pressure of 0.55MPa, a spraying angle of 15 degrees, and a sandblasting distance of 120mm , the surface roughness of the steel structure is Ra15um;

[0022] S2: preheating: preheating the pretreated steel structure at 250 degrees Celsius for 30 minutes;

[0023] S3: Spraying: Using multi-component alloy powder, supersonic flame spraying is carried out on the surface of the steel structure through supersonic flame spraying equipment. The spraying process parameters are: gas pressure 0.4MPa, oxygen pressure 0.65MPa, nitrogen pressure 0.35MPa, gas pressure Flow rate is 45L / min, oxygen flow rate is 460L / min, nitrogen flow rate is 135L / min; powder feeding speed is 125g / min, flame speed is 230m / s, flame temperature is 2...

Embodiment 2

[0026] The steel structure surface anticorrosion process includes the following steps:

[0027] S1: Pretreatment: Clean and derust the surface of the steel structure, and then use dry, compressed and oil-free air to perform sandblasting and roughening. The sandblasting pressure is 0.6MPa, the spraying angle is 20 degrees, and the sandblasting distance is 140mm. , the surface roughness of the steel structure is Ra20um;

[0028] S2: preheating: preheating the pretreated steel structure at 260 degrees Celsius for 35 minutes;

[0029] S3: Spraying: Using multi-component alloy powder, supersonic flame spraying is carried out on the surface of the steel structure through supersonic flame spraying equipment. The spraying process parameters are: gas pressure 0.42MPa, oxygen pressure 0.7MPa, nitrogen pressure 0.4MPa, gas pressure The flow rate is 50L / min, the oxygen flow rate is 470L / min, the nitrogen flow rate is 140L / min; the powder feeding speed is 130g / min, the flame speed is 240m...

Embodiment 3

[0032] The steel structure surface anticorrosion process includes the following steps:

[0033] S1: Pretreatment: Clean and derust the surface of the steel structure, and then conduct sandblasting roughening with dry, compressed and oil-free air, with a sandblasting pressure of 0.5MPa, a spraying angle of 10 degrees, and a sandblasting distance of 100mm , the surface roughness of the steel structure is Ra10um;

[0034] S2: preheating: preheating the pretreated steel structure at 240 degrees Celsius for 25 minutes;

[0035] S3: Spraying: Using multi-component alloy powder, supersonic flame spraying is carried out on the surface of the steel structure through supersonic flame spraying equipment. The spraying process parameters are: gas pressure 0.38MPa, oxygen pressure 0.6MPa, nitrogen pressure 0.3MPa, gas pressure The flow rate is 40L / min, the oxygen flow rate is 450L / min, the nitrogen flow rate is 130L / min; the powder feeding speed is 120g / min, the flame speed is 220m / s, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com