Device and method for measuring free variation of volume of cement paste under programmable temperature control

A technology of cement slurry and monitoring device, which is applied in the direction of volume measuring instrument/method, measuring device, temperature control, etc., can solve the problem that it cannot be used to measure the free change value of cement slurry volume, and its accuracy and reliability need further research. The problem of insignificant change in cement volume can achieve the effects of accurate and reliable measurement results, convenient device operation and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

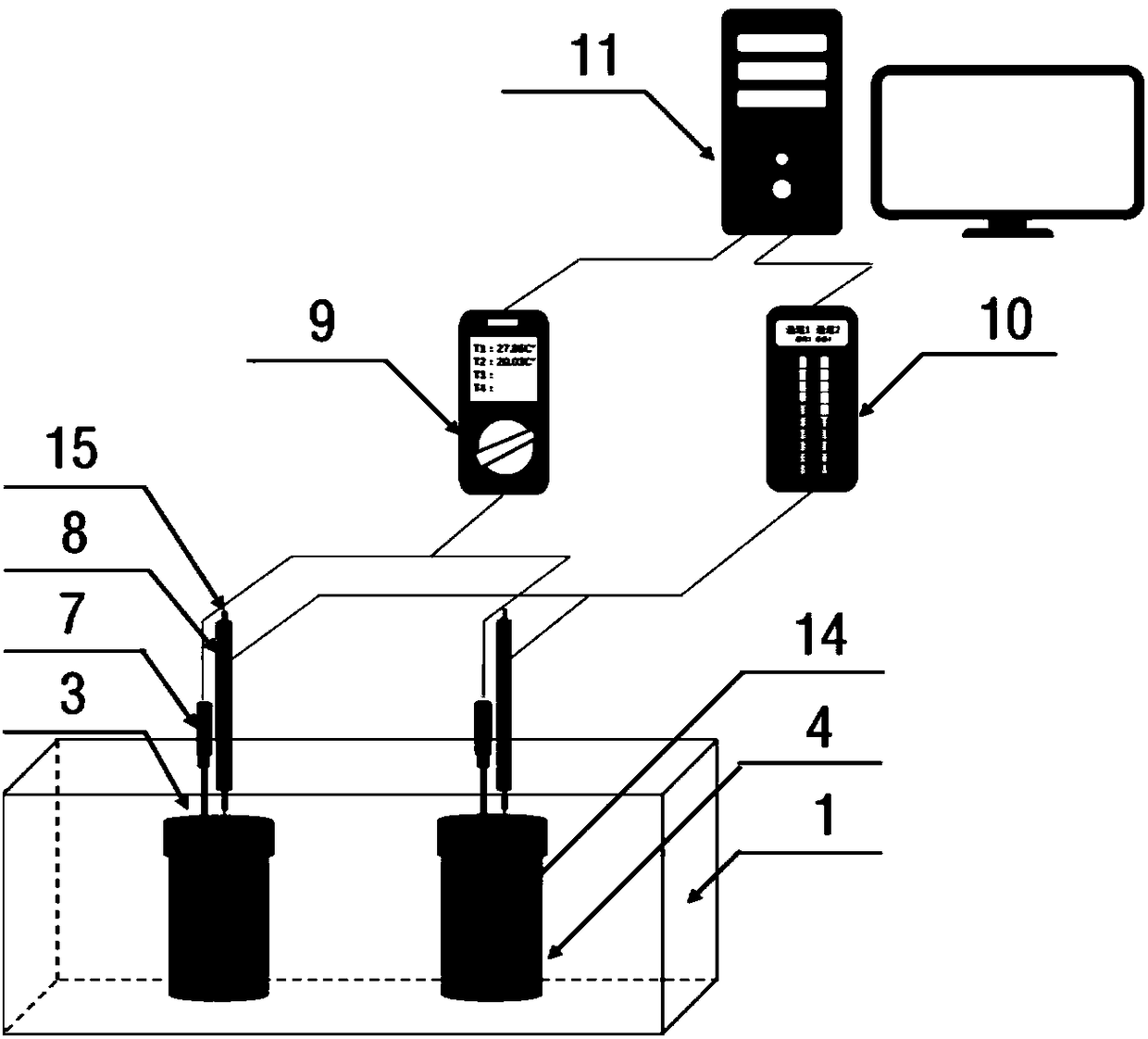

[0025] Such as figure 1 As shown, a device for measuring the free change of cement paste volume under program temperature control, including a material filling module, a data acquisition module and an information processing module; the temperature control program is a constant temperature condition: the material filling module includes a constant temperature water bath box 1 and The sealed glass cup 3 of sample A to be tested and the sealed glass cup 4 of sample B to be tested placed therein, the cups of the sealed glass cup 3 of sample A to be tested and the sealed glass cup 4 of sample B to be tested are all filled Hydrophobic oil 14; the data acquisition module includes a temperature monitoring thermocouple 7, a capillary glass liquid level gauge 15 and Liquid level photoelectric direct reader 8, and temperature monitor 9 and liquid level monitor 10 of signal monitoring conversion; Described information processing module comprises information processor 11; Described tempera...

Embodiment 2

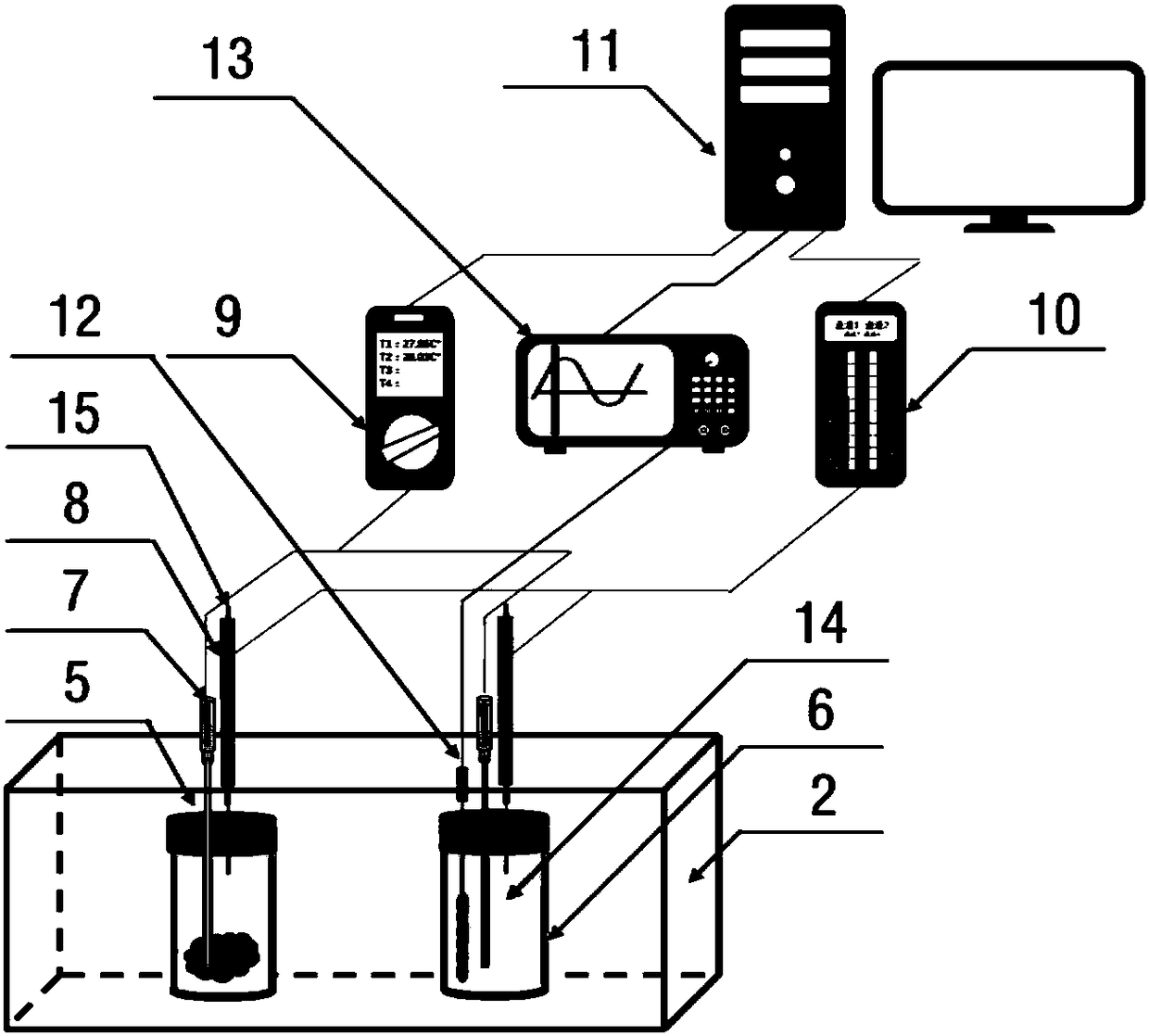

[0028] Such as figure 2 As shown, a device for measuring the free change of the volume of cement slurry under program temperature control, including a material filling module, a data acquisition module and an information processing module; the temperature control program is adiabatic condition: the material filling module includes a thermal insulation box 2 And the thermal insulation cup 5 of the sample to be tested and the thermal insulation cup 6 of the control group placed therein, the cups of the thermal insulation cup 5 of the sample to be tested and the thermal insulation cup 6 of the control group are all filled with hydrophobic oil 14. The data acquisition module includes a temperature monitoring thermocouple 7, a capillary glass tube liquid level gauge 15, and a liquid level photoelectric direct reader placed on the heat-insulated thermos cup 5 of the sample to be tested and the heat-insulated thermos cup 6 of the control group 8. The cold end compensation heat sourc...

Embodiment 3

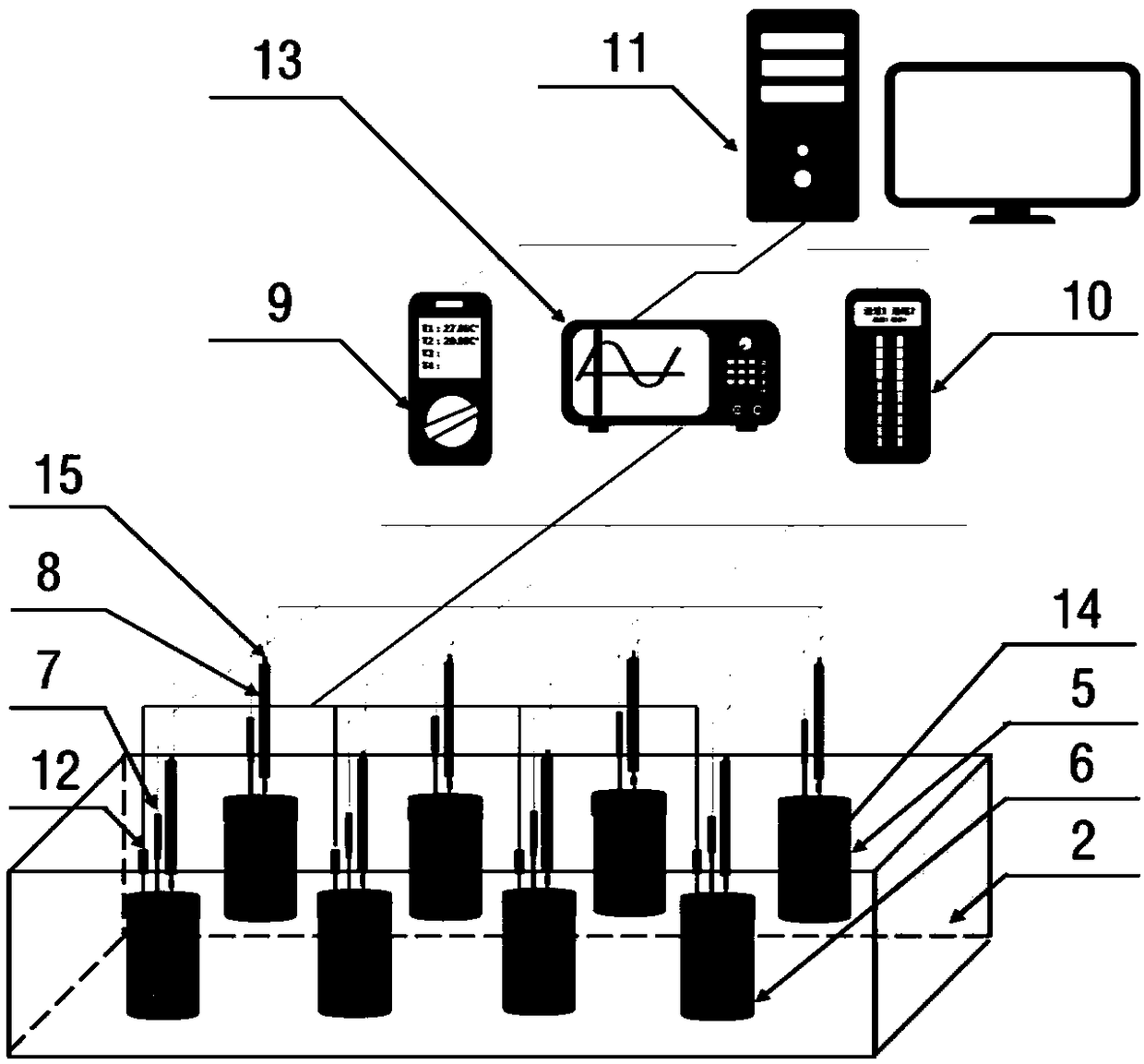

[0031] Such as image 3 As shown, the device of Example 3 and the temperature control degree of Example 2 are all conditions of adiabatic temperature rise, and the difference from Example 2 is mainly that the liquid level monitor 10 is an eight-channel monitor, which is used to connect eight liquid level monitors simultaneously. The photoelectric direct reader 8 carries out measurement records; the temperature monitor 9 is an eight-channel monitor for simultaneously connecting eight temperature monitoring thermocouples 7 for temperature measurement and recording; the power compensation controller 13 is a four-channel controller , for simultaneously connecting four cold-end compensation heat sources 12 to independently heat the hydrophobic oil 14 in the heat-insulated thermos cups 6 of the four control groups.

[0032] The device of this embodiment is equipped with eight-channel temperature and liquid level monitors, which can simultaneously and accurately measure the hydration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com