Material recycling method of waste lithium iron phosphate battery

A lithium iron phosphate battery and material recycling technology, applied in battery recycling, recycling technology, waste collector recycling and other directions, can solve the problems of high energy consumption, poor environmental friendliness, low lithium iron phosphate recycling efficiency, etc., to achieve energy consumption Low, environmentally friendly, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

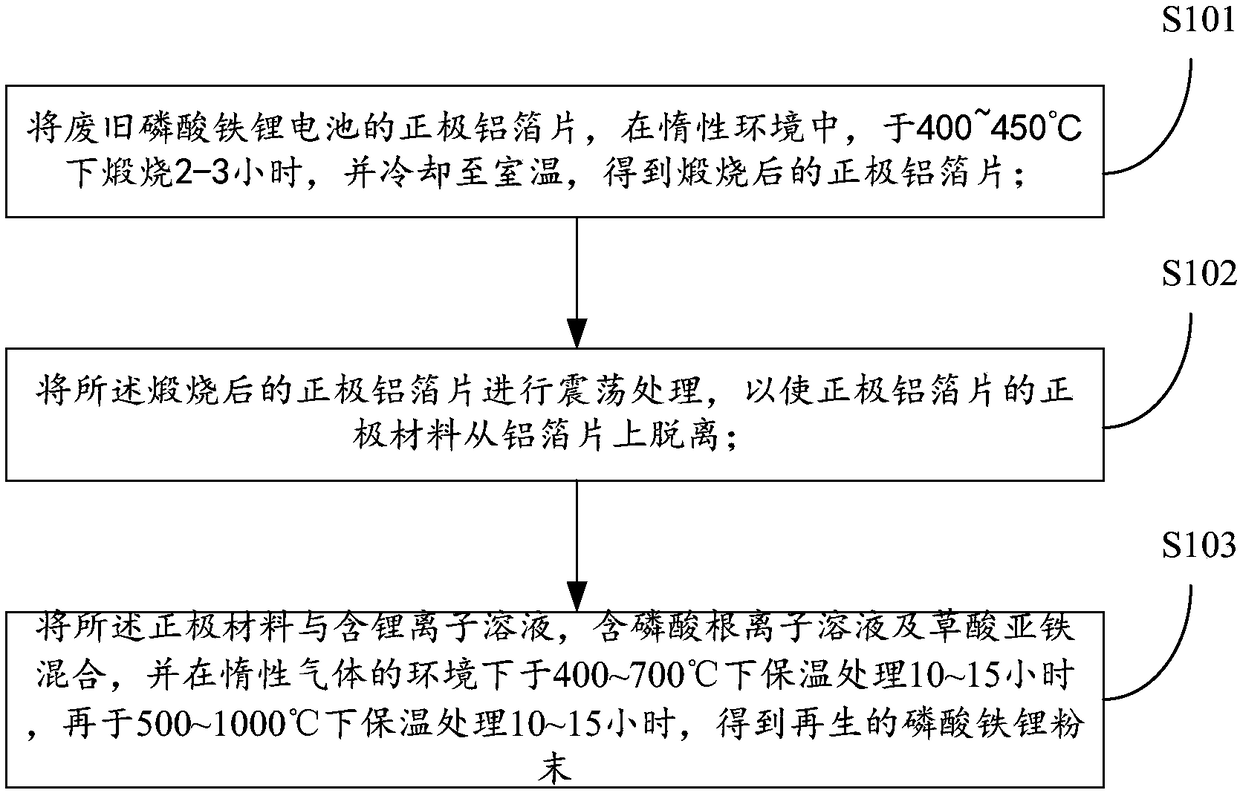

[0052] (1) Select the used new energy electric vehicle lithium iron phosphate battery, discharge it on professional discharge equipment, disassemble the battery after discharge, collect the positive and negative electrodes and separators inside the battery independently, and obtain the positive electrode of the battery piece.

[0053] (2) Put the obtained positive electrode sheet into a muffle furnace, pass nitrogen gas into the muffle furnace, and calcinate at 400 ° C for 2 hours. After cooling, the temperature drops to room temperature, and cut the positive electrode sheet to a size of 3 × 3 cm , put the cut positive electrode sheet into the mechanical vibrating screen, the positive electrode sheet is violently vibrated on the screen surface by the force of the vibration source, and the lithium iron phosphate on the electrode sheet is peeled off from the aluminum foil by the vibration force, so that the lithium iron phosphate and The aluminum foil is separated and passed thr...

Embodiment 2

[0059] (1) Select the used new energy electric vehicle lithium iron phosphate battery, discharge it on professional discharge equipment, disassemble the battery after discharge, collect the positive and negative electrodes and separators inside the battery independently, and obtain the positive electrode of the battery piece.

[0060] (2) Put the obtained positive electrode sheet into a muffle furnace, pass nitrogen gas into the muffle furnace, and calcinate at 430° C. for 2-3 hours. After cooling, the temperature drops to room temperature, and cut the positive electrode sheet to 5×5 centimeter size, put the cut positive electrode into the mechanical vibrating sieve, the positive electrode vibrates violently on the screen surface by the force of the vibration source, and the lithium iron phosphate on the electrode is peeled off from the aluminum foil by the vibration force, so that the iron phosphate Lithium is separated from the aluminum foil and passed through the screen qui...

Embodiment 3

[0066] (1) Select the used new energy electric vehicle lithium iron phosphate battery, discharge it on professional discharge equipment, disassemble the battery after discharge, collect the positive and negative electrodes and separators inside the battery independently, and obtain the positive electrode of the battery piece.

[0067] (2) Put the obtained positive electrode sheet into a muffle furnace, pass nitrogen gas into the muffle furnace, and calcinate at 450° C. for 2-3 hours. After cooling, the temperature drops to room temperature, and cut the positive electrode sheet to 5×5 centimeter size, put the cut positive electrode into the mechanical vibrating sieve, the positive electrode vibrates violently on the screen surface by the force of the vibration source, and the lithium iron phosphate on the electrode is peeled off from the aluminum foil by the vibration force, so that the iron phosphate Lithium is separated from the aluminum foil and passed through the screen qui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com