A kind of far-infrared heating material and composition thereof

A heating material and far-infrared technology, applied in the field of infrared radiation materials, can solve the problems of high frequency of dressing changes, large side effects, skin allergies, etc., achieve better effects, improve lattice vibration activity, and increase radiation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

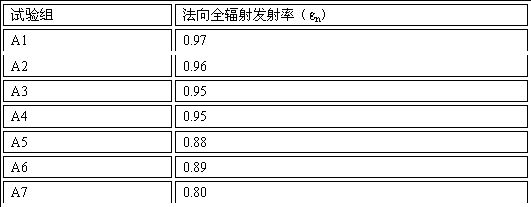

[0031] Embodiment 1, preparation of far-infrared heating material-far-infrared ceramic powder A1

[0032] Take 30 parts by weight AlCl 3 ·6H 2 O, 6 parts by weight MgCl 2 , 16 parts by weight ZrOCl 2 ·8H 2 O, 25 parts by weight TiCl 4 , 21 parts by weight SiCl 4 , 0.2 parts by weight PdCl 2 and 1.8 parts by weight LaCl 3 , respectively dissolved in deionized water; each reactant solution was added to a mixed solution of polyethylene glycol and carboxymethyl cellulose, mixed and stirred, then added ammonia water with a concentration of 4 mol / L, put into a centrifuge, and washed with water to obtain a precipitate The precipitate is dehydrated by weight ratio Span-60: Tween-60: OP-10=2:2:1 mixed solution, dried at 70°C for 3 hours, calcined at 1300°C for 6 hours, and then crushed by air flow to obtain far-infrared Ceramic powder A1.

Embodiment 2

[0033] Embodiment 2, preparation of far-infrared heating material-far-infrared ceramic powder A2

[0034] Take 30 parts by weight AlCl 3 ·6H 2 O, 6 parts by weight MgCl 2 , 16 parts by weight ZrOCl 2 ·8H 2 O, 25 parts by weight TiCl 4 , 21 parts by weight SiCl 4 , 0.25 parts by weight PdCl 2 and 1.75 parts by weight LaCl 3, respectively dissolved in deionized water; each reactant solution was added to a mixed solution of polyethylene glycol and carboxymethyl cellulose, mixed and stirred, then added with ammonia water with a concentration of 4mol / L, put into a centrifuge and washed with water to obtain a precipitate ; The precipitate is dehydrated by weight ratio Span-60:Tween-60:OP-10=2:2:1 mixed solution, dried at 70°C for 3 hours, calcined at 1300°C for 6 hours, and then crushed by airflow to obtain far-infrared ceramics Powder A2.

Embodiment 3

[0035] Embodiment 3, preparation of far-infrared heating material-far-infrared ceramic powder A3

[0036] Take 30 parts by weight AlCl 3 ·6H 2 O, 6 parts by weight MgCl 2 , 16 parts by weight ZrOCl 2 ·8H 2 O, 25 parts by weight TiCl 4 , 21 parts by weight SiCl 4 , 0.15 parts by weight PdCl 2 and 1.85 parts by weight LaCl 3 , respectively dissolved in deionized water; each reactant solution was added to a mixed solution of polyethylene glycol and carboxymethyl cellulose, mixed and stirred, then added with ammonia water with a concentration of 4mol / L, put into a centrifuge and washed with water to obtain a precipitate ; The precipitate is dehydrated by weight ratio Span-60:Tween-60:OP-10=2:2:1 mixed solution, dried at 70°C for 3 hours, calcined at 1300°C for 6 hours, and then crushed by airflow to obtain far-infrared ceramics Powder A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com