Double-L-shaped rectangular steel box type composite shear wall

A combined shear wall and shear wall technology, applied in the direction of walls, building materials, building components, etc., can solve the problems that the assembly quality of vertical components is not easy to guarantee, restricts the promotion of steel structure houses, and is prone to problems in transportation and installation. Achieve the effect of simple construction, excellent mechanical performance and superior mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

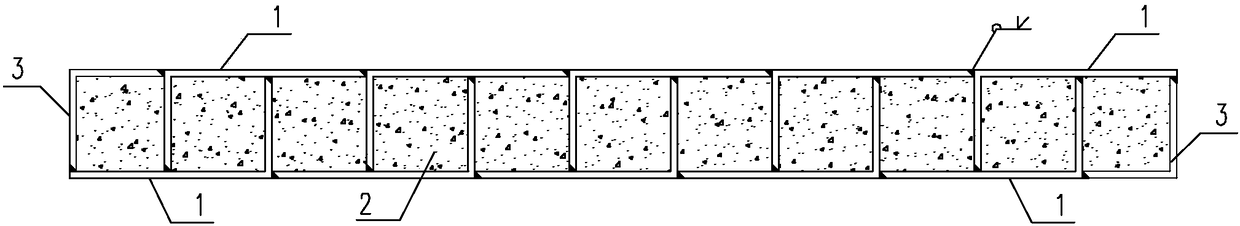

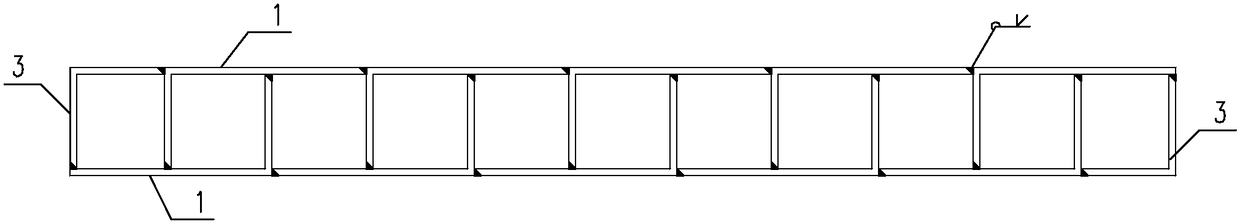

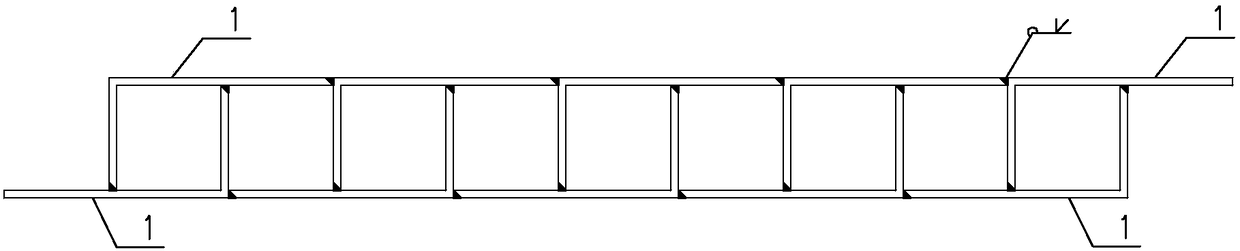

[0042] The embodiment of double L-shaped rectangular steel box type combined shear wall of the present invention is as follows Figure 1 to Figure 7 As shown, the shear wall includes a steel box skeleton. The steel box skeleton includes a plurality of internode units arranged continuously. Adjacent internode units are welded. Each internode unit consists of two pairs of identical structures. The right-angle steel plate 1 is welded. The right-angle steel plate 1 is L-shaped. Two right-angle steel plates 1 form a double-L shape, that is, each internode unit is a double-L-shaped assembly composed of two L-shaped right-angle steel plates. The right-angle steel plate 1 There are long right-angled sides 11 and short right-angled sides 12, and the length of the long right-angled sides 11 is 2 times of the length of the short right-angled sides 12. The short right-angled sides 12 of 1 are welded together, and the welding place between the short right-angled side 12 and the long right-...

Embodiment 2

[0046] Embodiment two of the double L-shaped rectangular steel box type combined shear wall of the present invention is as Figure 8 to Figure 11 As shown, the difference from Embodiment 1 is that the shear wall is an L-shaped wall, and the sealing plate includes an equilateral L-shaped end plate 3 with two equal-length right-angled sides and a straight steel plate 4, and the L-shaped end plate 3 Set at the wall end position and the wall corner position, the inline steel plate 4 is arranged in the wall corner position, the side length of the L-shaped end plate 3, and the length of the inline steel plate 4 are equal to the length of the short right-angled side 12, and the L-shaped end plate 3 It is welded with the adjacent right-angle steel plate 1, and the in-line steel plate 4 is welded with the adjacent L-shaped end plate 3 and the right-angle steel plate 1.

[0047] In this embodiment, the L-shaped end plate 3 is connected to the adjacent right-angle steel plate 1 by equal-...

Embodiment 3

[0049] Three examples of embodiment of double L-shaped rectangular steel box type composite shear wall of the present invention Figure 12 to Figure 14 As shown, the difference from Embodiment 1 is that the shear wall is a T-shaped wall, and the sealing plate includes an equilateral L-shaped end plate 3 with two equal-length right-angled sides and a straight steel plate 4, and the L-shaped end plate 3 Set at the wall end position, the inline steel plate 4 is arranged in the corner position of the wall, the side length of the L-shaped end plate 3, the length of the inline steel plate 4 are all equal to the length of the short right-angled side 12, the L-shaped end plate 3 and the adjacent The right-angle steel plate 1 is welded, and the in-line steel plate 4 is welded to the adjacent right-angle steel plate 1.

[0050] In this embodiment, the L-shaped end plate 3 is connected to the adjacent right-angle steel plate 1 by equal-strength groove welding, and the in-line steel plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com