Room-temperature curing polyurethane material as well as preparation method and application thereof

A polyurethane material, room temperature curing technology, applied in the field of polymer materials, can solve the problems of no green environmental protection, achieve flexible and adjustable curing time, good fluidity, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of room temperature curing polyurethane material, the steps are as follows:

[0028] Step 1. Mix the pre-dehydrated polyol and isocyanate in a mass ratio of 1:(0.5-4), stir and react at 60-80°C for 1-3h, and the stirring speed is 200-1200rpm / min to obtain NCO-terminated polyurethane prepolymerization Body, that is, component A, titrate its NCO value after the reaction is completed, preferably the NCO value range is 12-23%;

[0029] Step 2, blending and dehydrating the polyol and the small molecule chain extender in a mass ratio of 1:(0.05-0.2), then adding a catalyst, stirring evenly to obtain component B;

[0030] Step 3: Weighing component A and component B according to the chain extension coefficient of 0.95, sealing and subpackaging to obtain a room temperature curing polyurethane material;

[0031] It is also possible to further mix the A component and the B component weighed according to the chain extension coefficient of 0.95, stir evenly,...

Embodiment 1

[0039] Step 1. Add 200g of PTMEG-1000 into a 1L three-necked flask, place the flask in an oil bath at 120°C, and prepare a thermometer, a stirring paddle, and a double-row tube for each of the three-necked flasks. After ensuring airtightness, vacuumize under stirring at 200rpm / min. After 2 hours, ensure that the pressure in the bottle is stable below 400pa, then cool down to 70°C, add 400g of MDI, stir at 400rpm / min for 2 hours, and after cooling, component A is obtained. , the NCO content value of sampling and titration is 19.60%, poured out and sealed for preservation.

[0040]Step 2: Add 500g of PPG-1000 and 28.0g of BDO into a 1L single-necked flask, place the flask in an oil bath at 120°C, and vacuumize under stirring at 400rpm / min. After 2 hours, ensure that the pressure in the bottle is stable at Below 400pa, after cooling to room temperature, add 0.35g N,N dimethylbenzylamine, stir for 2min to obtain component B, pour it out and seal it for storage.

[0041] Step 3. S...

Embodiment 2

[0044] Step 1. Add 240g of PTMEG-1000 into a 1L three-neck flask, place the flask in an oil bath at 120°C, and equip the three ports with a thermometer, a stirring paddle, and a double-row tube respectively. After ensuring airtightness, vacuumize under stirring at 200rpm / min. After 2 hours, ensure that the pressure in the bottle is stable below 400pa, then cool down to 70°C, add 321g of MDI, stir at 400rpm / min for 2 hours, and after cooling, component A is obtained. , the NCO content value of sampling analysis was 15.63%, poured out and sealed for preservation.

[0045] Step 2. Add 400g of PTMEG-650 and 71.5g of BDO into a 1L single-necked flask, place the flask in an oil bath at 120°C, and vacuumize under stirring at 400rpm / min. After 2 hours, ensure that the pressure in the bottle is stable at Below 400pa, after cooling to room temperature, add 0.37g N,N dimethylbenzylamine, stir for 2min to obtain component B, pour it out and seal it for storage.

[0046] Step 3. Shake com...

PUM

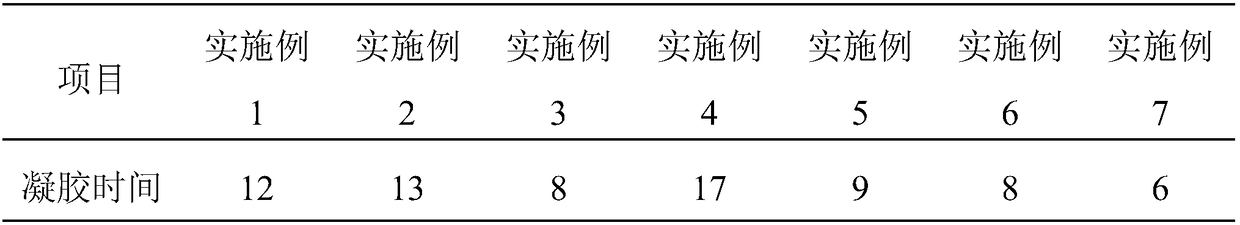

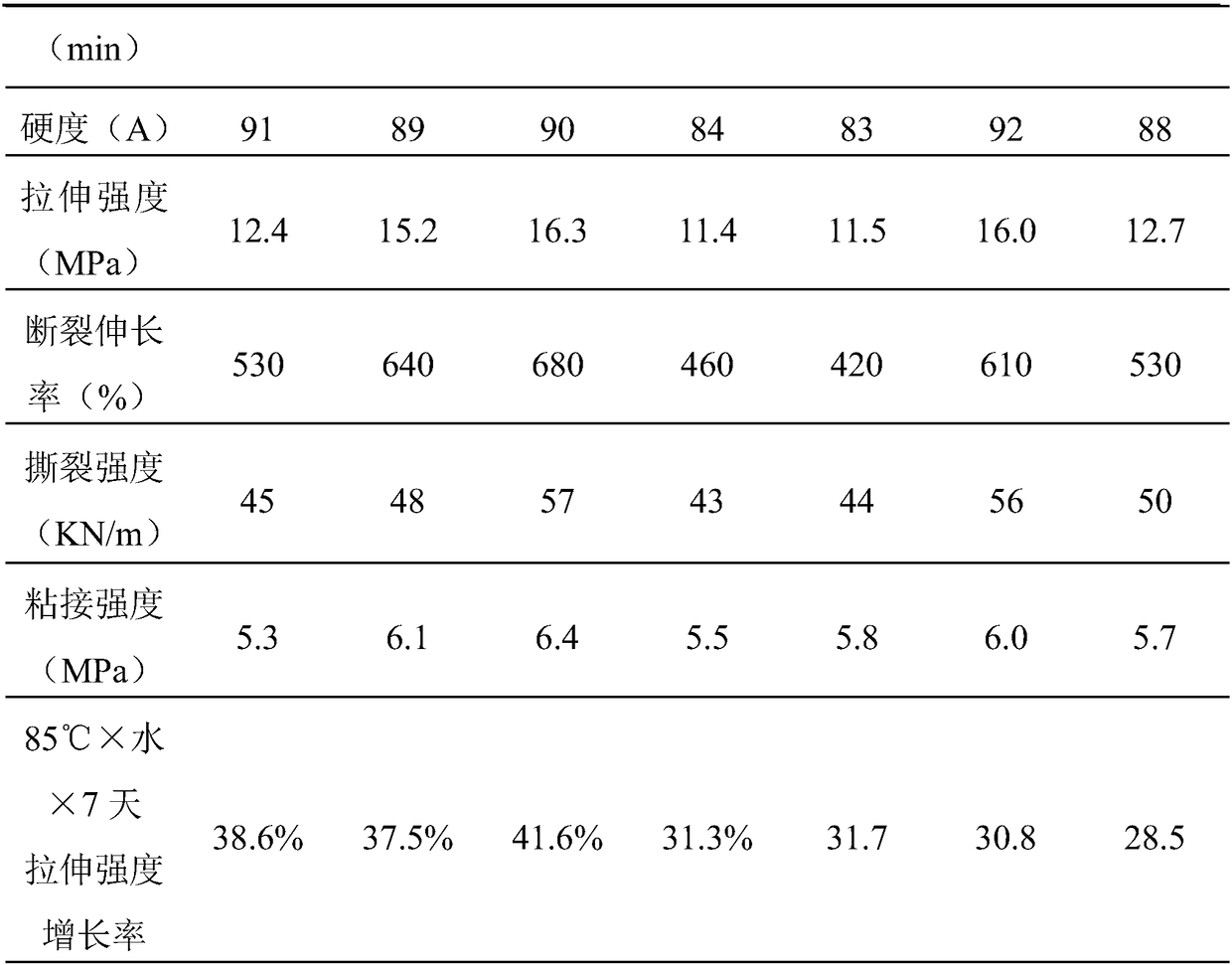

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com