A kind of halogen-free flame retardant and resin alloy containing said halogen-free flame retardant

A flame retardant and halogen compound technology, which is applied in the field of halogen-free flame retardants and resin alloys containing the halogen-free flame retardants, can solve the problems of inability to meet the flame retardant grade, low addition amount, influence on mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

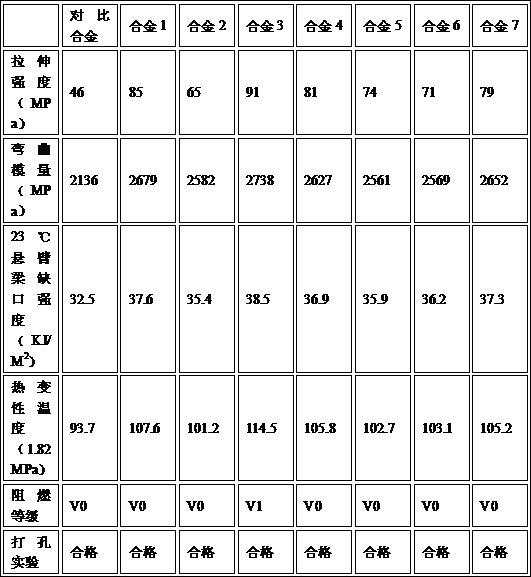

Examples

Embodiment 1

[0018] The invention provides a resin alloy, which is composed of the following components: 40 parts by weight of polycarbonate resin, 24 parts by weight of acrylonitrile-butadiene-styrene copolymer, 13 parts by weight of halogen-free flame retardant, 8 parts by weight of Compatibility agent and 3.6 parts by weight processing aid; Described compatibilizer is made up of following components: 42 parts by weight diene oligomers, 12 parts by weight maleic anhydride and 9 parts by weight acrylic acid; Described diene oligomers are made of 2 parts by weight of butadiene oligomers with an average relative molecular mass of 600-2000 g / mol, 3 parts by weight of pentadiene oligomers with an average relative molecular mass of 1200-3000 g / mol and 5 parts by weight of relative Molecular mass is the hexadiene oligomer composition of 2400-3600g / mol; Described processing aid comprises antioxidant, lubricant and release agent, and described antioxidant is made of 1.6 parts by weight of citric a...

Embodiment 2

[0022] The invention provides a resin alloy, which is composed of the following components: 43 parts by weight of polycarbonate resin, 20 parts by weight of acrylonitrile-butadiene-styrene copolymer, 21 parts by weight of halogen-free flame retardant, 6 parts by weight of Compatibility agent and 2.4 parts by weight processing aid; Described compatibilizer is made up of following components: 34 parts by weight diene oligomers, 16 parts by weight maleic anhydride and 3 parts by weight acrylic acid; Described diene oligomers are made of 1 part by weight of a butadiene oligomer with an average relative molecular mass of 600-2000 g / mol, 2 parts by weight of a pentadiene oligomer with an average relative molecular mass of 1200-3000 g / mol and 4 parts by weight of a relative The composition of hexadiene oligomers with a molecular mass of 2400-3600 g / mol; the composition of the processing aid is the same as that of the processing aid in Example 1.

[0023] Wherein, the halogen-free fla...

Embodiment 3

[0026] The invention provides a polyphenylene ether resin alloy, which is composed of the following components: 48 parts by weight of polycarbonate resin, 26 parts by weight of acrylonitrile-butadiene-styrene copolymer, 6 parts by weight of halogen-free flame retardant, 9 parts by weight Parts by weight compatibilizer and 2 parts by weight processing aid; Described compatibilizer is made up of following components: 48 parts by weight diene oligomers, 8 parts by weight maleic anhydride and 11 parts by weight acrylic acid; Described diene low The polymer consists of 3 parts by weight of a butadiene oligomer with an average relative molecular mass of 600-2000g / mol, 3 parts by weight of a pentadiene oligomer with an average relative molecular mass of 1200-3000g / mol and 3 parts by weight The composition of hexadiene oligomers with a weight-average relative molecular mass of 2400-3600 g / mol; the composition of the processing aid is the same as that of the processing aid in Example 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com