Preparation method of nylon 65 salt

A nylon and solution technology is applied in the preparation field of nylon 65 salt, which can solve the problems of difficulty in determining the reaction end point, concentration and purification, etc., and achieve the effects of easy control of the reaction end point, reduction of oxidative deterioration and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

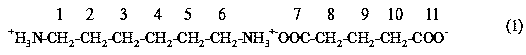

Method used

Image

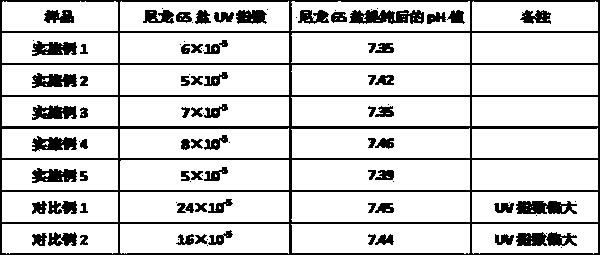

Examples

Embodiment 1

[0030] The preparation method of the nylon 65 salt of the present embodiment, the steps are as follows:

[0031] (1) Weigh 13.20g (0.10mol) of glutaric acid and dissolve it in water to make a glutaric acid solution with a concentration of 45%, and heat it to 45°C; then take 11.60g (0.10mol) of hexamethylenediamine and dissolve it in water , form a hexamethylenediamine solution with a concentration of 55%, and heat to 45°C;

[0032] (2) Add the hexamethylenediamine solution dropwise to the glutaric acid solution at 1.2mL / min under stirring at a constant rate of 110r / min. During this process, the air is replaced three times by vacuuming and filling with nitrogen, and nitrogen is introduced for protection. Use a pH meter to monitor the pH in real time, control the pH to be stable at 7.30-7.50, and maintain the reaction time at 2.5 hours to make it fully react;

[0033] (3) After fully reacting, vacuum distillation was carried out under airtight conditions, and then nylon 65 salt...

Embodiment 2

[0036] The preparation method of the nylon 65 salt of the present embodiment, the steps are as follows:

[0037] (1) Weigh 13.20g (0.10mol) of glutaric acid and dissolve it in water to make a glutaric acid solution with a concentration of 50%, and heat it to 50°C; then take 11.68g (0.10mol) of hexamethylenediamine and dissolve it in water , form a hexamethylenediamine solution with a concentration of 55%, and heat to 50°C;

[0038] (2) Add the hexamethylenediamine solution dropwise to the glutaric acid solution at 1.3mL / min under stirring at a constant rate of 110r / min. During this process, the air in the solution is replaced three times by vacuuming and filling with nitrogen, and nitrogen is introduced for protection. Use a pH meter to monitor the pH in real time. The reaction time is maintained at 2.5 hours to allow it to fully react, and then the pH is stabilized at 7.30~7.50;

[0039](3) After fully reacting, vacuum distillation was carried out under airtight conditions, ...

Embodiment 3

[0042] The preparation method of the nylon 65 salt of the present embodiment, the steps are as follows:

[0043] (1) Weigh 39.60g (0.30mol) of glutaric acid and dissolve it in water to make a glutaric acid solution with a concentration of 45%, and heat it to 45°C; then take 34.80g (0.30mol) of hexamethylenediamine and dissolve it in In water, a hexamethylenediamine solution with a concentration of 55% is formed and heated to 45°C;

[0044] (2) Add the hexamethylenediamine solution dropwise to the glutaric acid solution at 1.2mL / min under stirring at a constant rate of 110r / min. During this process, the air in the solution is replaced by vacuuming and filling with nitrogen for three times and nitrogen is introduced for protection. Use a pH meter to monitor the pH in real time, control the pH to be stable at 7.30-7.50, and maintain the reaction time at 2.5 hours to make it fully react;

[0045] (3) After fully reacting, vacuum distillation was carried out under airtight conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com