Stirring device for honey production

A stirring device, honey technology, applied in mixers with rotating stirring devices, applications, food forming, etc., can solve the problems of poor production and preservation of honey, insufficient stirring uniformity, and unobvious impurity removal effect, etc. Achieve good preservation, quality improvement, and easy mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

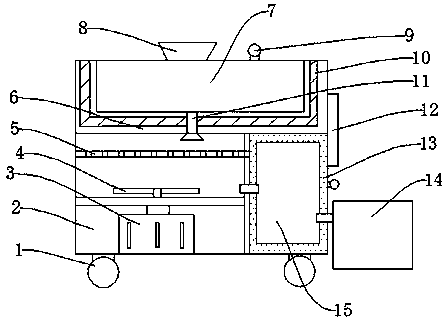

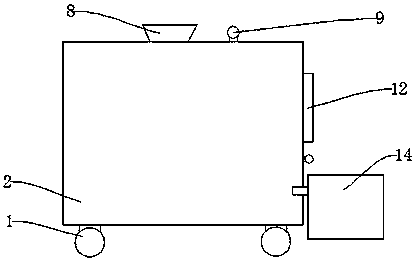

[0019] The present invention will be further described below in conjunction with accompanying drawing:

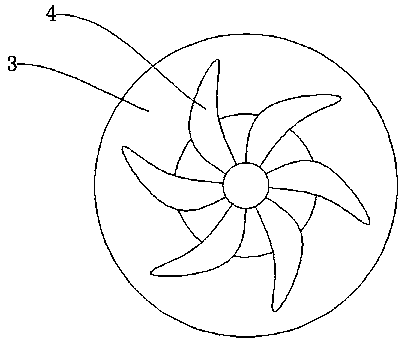

[0020] Such as Figure 1-Figure 3 As shown, a stirring device for honey production includes a storage tank 14, a motor 3, a stirring paddle 4, a main box body 2, and a control panel 12. The bottom of the main box body 2 is provided with a roller 1, which can allow the The machine is more convenient to move. There is a motor 3 inside the main box 2. The motor 3 provides power to the stirring paddle 4. The stirring paddle 4 is arranged above the motor 3. The stirring paddle 4 rotates to fully stir the honey, and the stirring paddle 4 top is provided with filter screen 5, and filter screen 5 can remove redundant impurity or bulk crystal, and the top of filter screen 5 is provided with heat shield 6, and heat shield 6 can make the temperature in melting tank 7 not easy to lose, Heat insulation board 6 is provided with heating plate 10 inside, and heating plate 10 is heated to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com