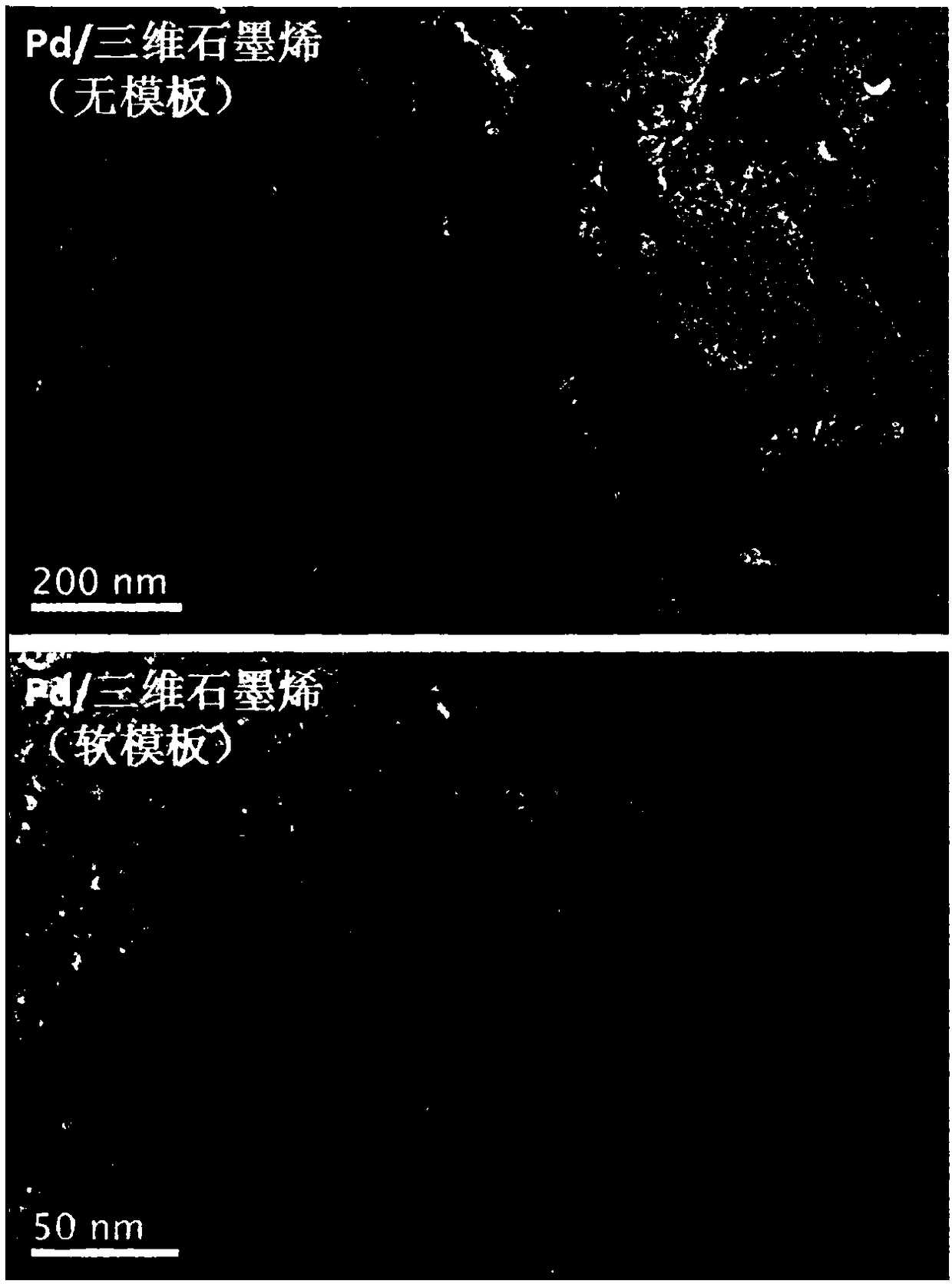

Method for preparing three-dimensional graphene supported nano Pd catalyst with soft template method and application of catalyst to nitrobenzene hydrogenation

A soft template method, graphene technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of Pd metal particle size is too large, recycling rate Low, lamellar stacking and other problems, to achieve the effect of good catalytic activity and reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 0.04g of graphite oxide and add it into 25mL emulsion (15mL deionized water, 5mL ethanol, 5mL cyclohexane), treat it with ultrasonic, ultrasonic frequency is 180W, room temperature ultrasonic 1.5h, then add 80mg of ascorbic acid to the solution, water bath Heat at 90°C for 0.5h, then add 0.5mL of 0.02mol / L PdCl 2 The solution was stirred and reacted in an oil bath at 100° C. for 2 hours. After the reaction, it was centrifuged, washed 5 times with deionized water and 2 times with ethanol, and dried in vacuum at 50° C. for 2 hours to obtain the catalyst A.

Embodiment 2

[0018] Weigh 0.04g of graphite oxide and add it into 16.6mL of emulsion (10mL of deionized water, 3.3mL of ethanol, 3.3mL of cyclohexane), sonicate it at an ultrasonic frequency of 180W, ultrasonicate at room temperature for 1.5h, and then add 80mg of Ascorbic acid, heated in a water bath at 90°C for 0.5h, then added 0.5mL of 0.02mol / L PdCl 2 The solution was stirred in an oil bath at 100° C. for 2 h, centrifuged after the reaction, washed 5 times with deionized water and 2 times with ethanol, and vacuum-dried at 50° C. for 2 h to obtain the catalyst B.

Embodiment 3

[0020] Weigh 0.04g of graphite oxide and add it into 8mL emulsion (6mL deionized water, 2mL ethanol, 2mL cyclohexane), treat it with ultrasonic, ultrasonic frequency is 180W, room temperature ultrasonic 1.5h, then add 80mg of ascorbic acid to the solution, water bath Heat at 90°C for 0.5h, then add 0.5mL of 0.02mol / L PdCl 2 The solution was stirred in an oil bath at 100° C. for 2 hours. After the reaction, it was centrifuged, washed 5 times with deionized water and 2 times with ethanol, and dried in vacuum at 50° C. for 2 hours to obtain the catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com