A method and device for controlling jet breakage and droplet generation

A technology for droplet generation and jet control, which is used in chemical instruments and methods, measuring tubes/pipettes, laboratory containers, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

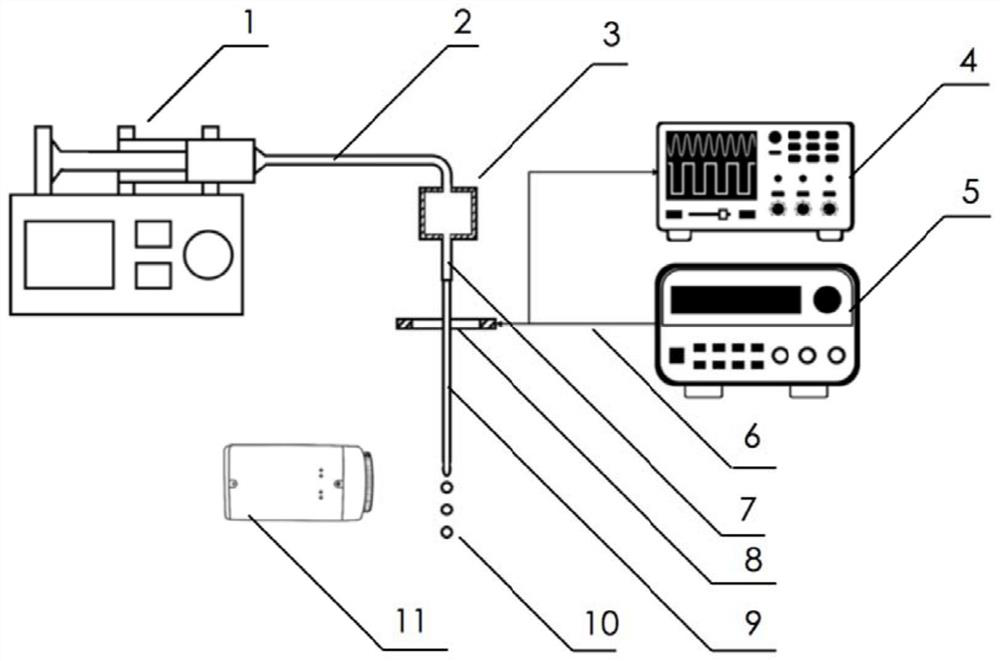

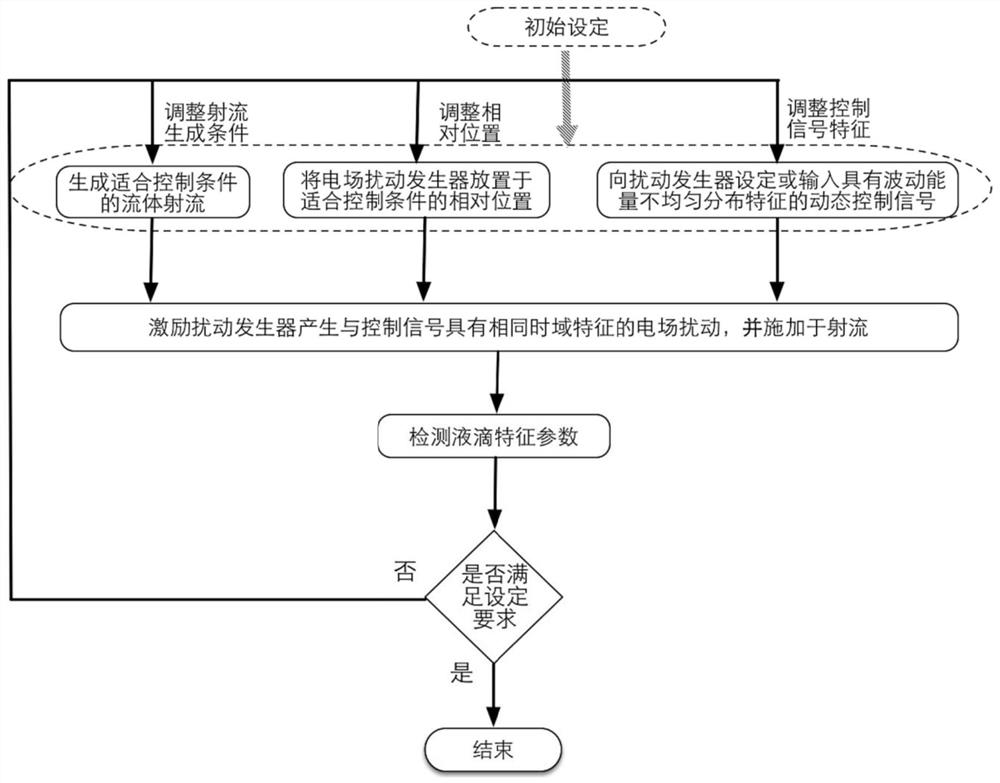

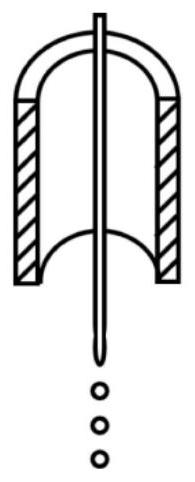

[0042] see figure 1 , is a schematic diagram of an embodiment of a device for controlling jet breakage and droplet generation provided by the present invention. A device for controlling jet breakage and droplet generation, including a disturbance signal generator and a disturbance component, the disturbance signal generator is used to set or input a dynamic disturbance signal with a characteristic of uneven distribution of fluctuating energy, and the disturbance component is connected to the disturbance signal generator, Generate fluctuations with synchronous time-domain characteristics, and act on the continuous segment of fluid jet in a non-contact manner, so that the size and distance of individual droplets produced by the continuous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com