Coating machine capable of reducing air pollution

An air pollution and spraying machine technology, applied in the field of spraying machines that can reduce air pollution, can solve problems such as polluted environment and health damage of workers, and achieve the effects of reducing pollution, improving working environment and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

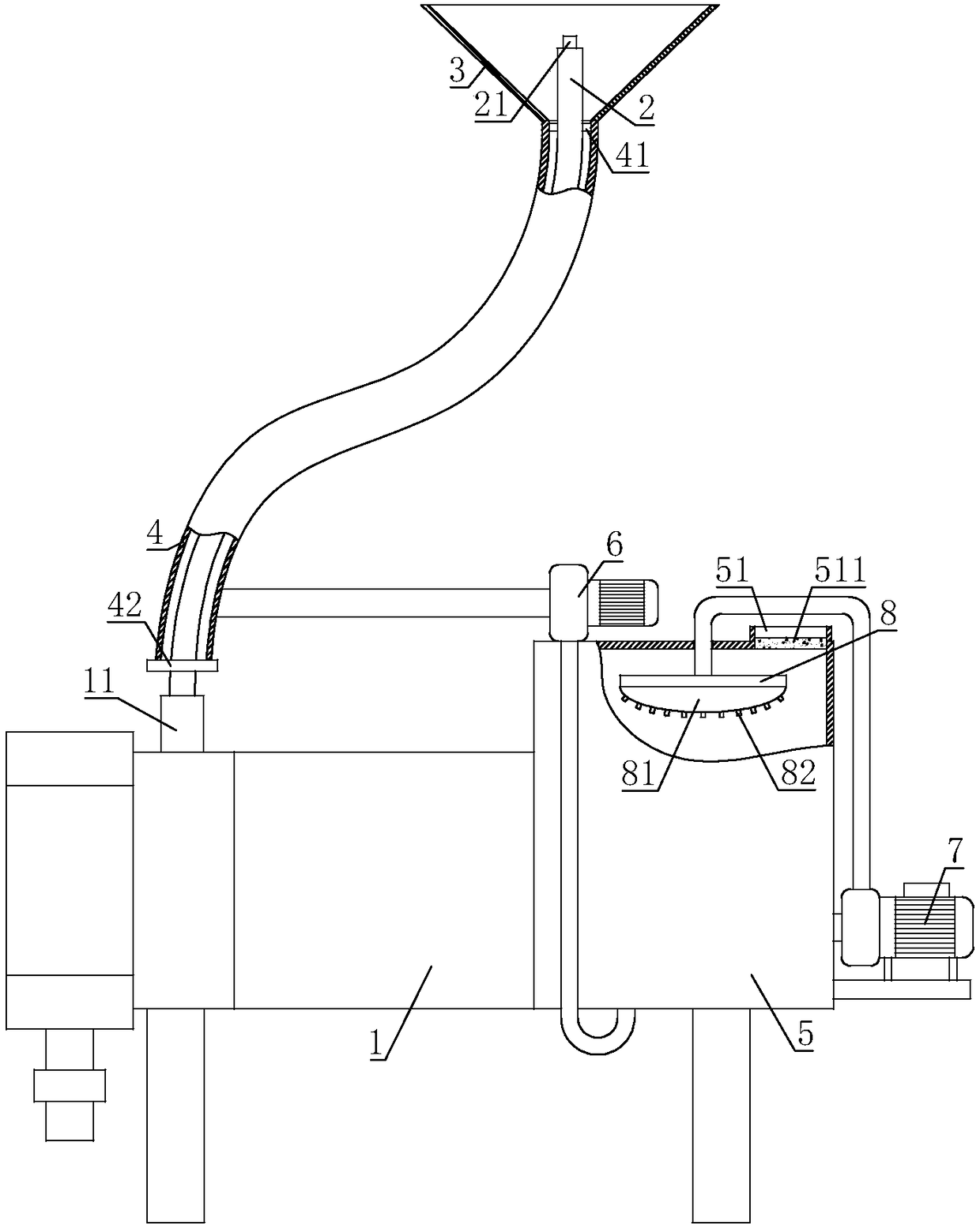

[0025] A spraying machine capable of reducing air pollution, comprising a spraying machine main body 1, a screw pump 11 is connected to the spraying machine main body 1, a spraying pipe 2 is connected to the outlet of the screw pump 11, and a spray nozzle 21 is connected to the end of the spraying pipe 2. The spray nozzle 21 is covered with an umbrella cover 3, and the umbrella cover 3 is connected with an exhaust pipe 4; a water tank 5 is installed on the main body 1 of the spraying machine, an exhaust port 51 is arranged on the water tank 5, and an exhaust fan is installed on the water tank 5 6. The air inlet of the exhaust fan 6 communicates with the exhaust pipe 4 through a pipeline, and the air outlet of the exhaust fan 6 communicates with the water tank 5 through a pipeline.

[0026] Spray head 21 overcoat of the present invention is provided with umbrella cover 3, then in the spraying process, umbrella cover 3 can stop unnecessary paint mist from being diffused into the ...

Embodiment 2

[0028] On the basis of embodiment one, the exhaust pipe 4 is sleeved outside the spray pipe 2, and the end of the exhaust pipe 4 connected to the umbrella cover 3 is connected with a support frame 41 between the spray pipe 2, and the exhaust pipe 4 The other end is connected with a sealing plate 42, and the sealing plate 42 is fixed on the spraying pipe 2, and the pipeline connected to the air inlet of the exhaust fan 6 communicates with the end of the exhaust pipe 4 near the sealing plate 42.

[0029] Since the exhaust pipe 4 is sleeved on the spray pipe 2, in the process of using the present invention, the staff only need to pull a rope to extend the spray head 21 to the position to be sprayed, which is more convenient to operate and avoids exhaust. The case where the tube 4 is entangled and the paint mist cannot be discharged normally.

Embodiment 3

[0031] On the basis of Embodiment 1 or Embodiment 2, the pipe connected to the air outlet of the exhaust fan 6 is connected to the bottom of the water tank 5 .

[0032] The paint mist pumped by the exhaust fan 6 enters the water tank 5 from the bottom of the water tank 5, so that the paint mist can be fully mixed with the water in the water tank 5 to ensure that the paint mist can be more fully dissolved in the water and reduce the volatilization of the paint mist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com