Medium low temperature co-fired ceramic material and preparation method thereof

A low-temperature co-fired ceramic and intermediary technology, applied in the field of ceramic materials, can solve the problems of reduced microwave performance of matrix materials, difficult grinding and fine processing, large equipment loss, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

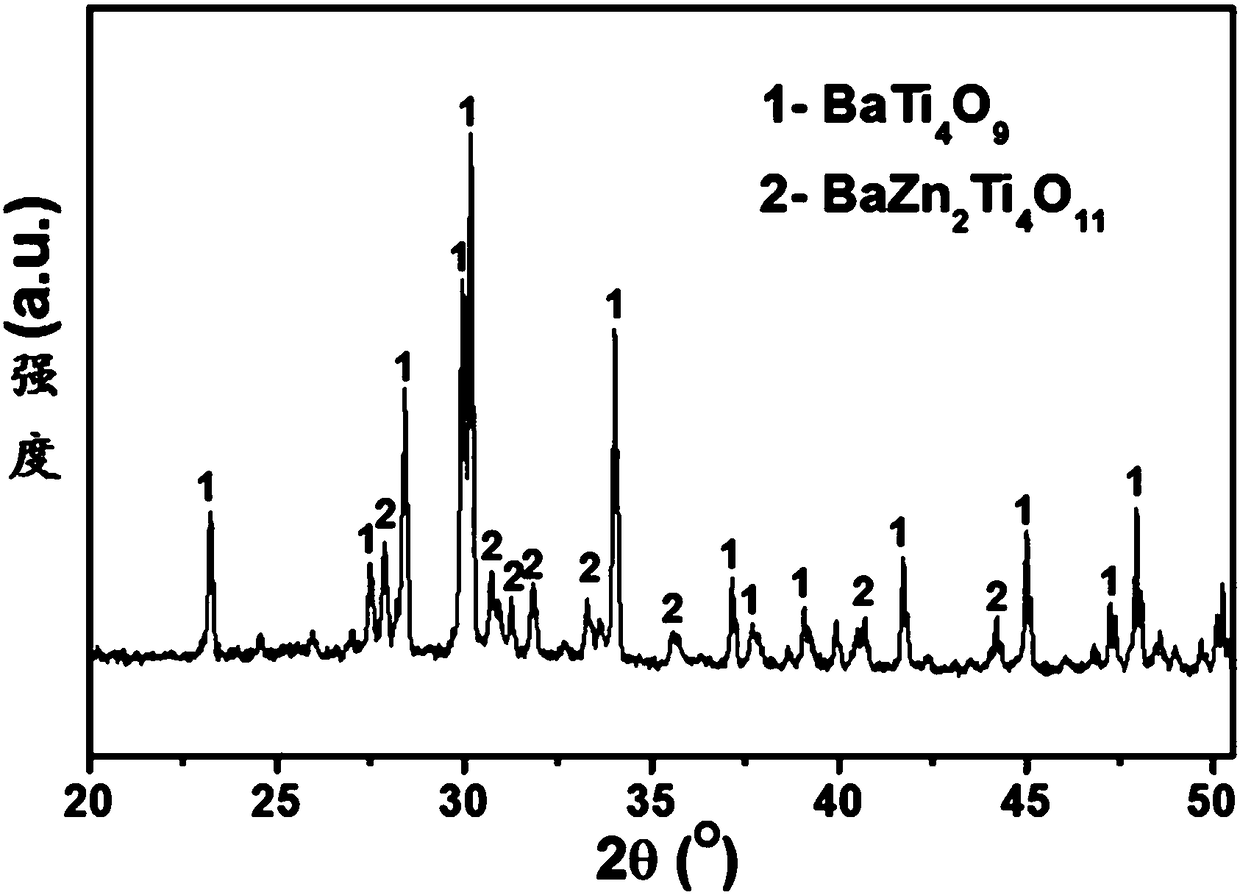

[0039] The pure BaCO will first be analyzed 3 , ZnO and TiO 2 The powder is prepared according to the ratio of mass and number of parts 37:5:58, and then the prepared powder is ball milled, dried, and sieved in sequence, and then calcined at 1200 ° C and kept for 2 hours, and then the calcined powder is passed through 100 Mesh sieve to get Ba-Zn-Ti compound.

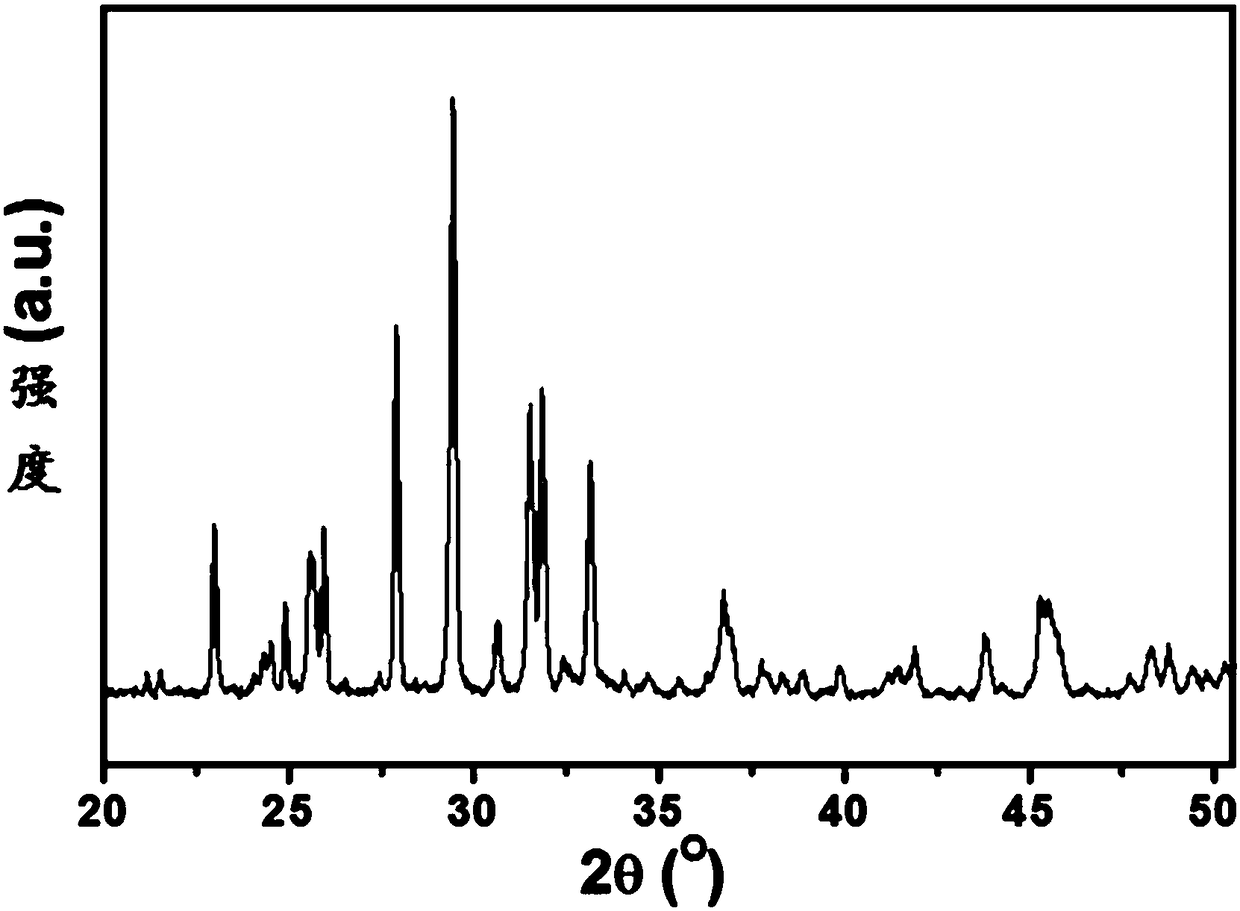

[0040] Analytical pure Bi 2 o 3 、H 3 BO 3 , SiO 2 and ZnO according to the mass-number ratio of 70:15:5:10, and then the prepared powder was ball-milled, dried, sieved, calcined at 600°C, and kept for 2 hours. The calcined powder Cross 100 mesh sieves to obtain powder material A.

[0041] Get the Ba-Zn-Ti compound of 60 mass parts, the powder A of 37 mass parts and the SrTiO of 3 mass parts 3 Prepare powder. Put the prepared powder into a ball mill for mixing. The mass ratio of balls, materials, and deionized water in the ball mill is 3:1:3. The grinding balls are zirconia balls. The ball milling time is 4 hours...

Embodiment 2

[0044] The pure BaCO will first be analyzed 3 , ZnO and TiO 2 Prepare the powder according to the mass-number ratio of 34:10:56, then ball mill, dry, and sieve the prepared powder in sequence, then calcinate at 1180°C and keep it warm for 2 hours, and then pass the calcined powder through 100 mesh Sieve to get Ba-Zn-Ti compound.

[0045] Analytical pure Bi 2 o 3 、H 3 BO 3 , SiO 2 and ZnO according to the mass-number ratio of 60:18:10:12. The prepared powder was ball-milled, dried, and sieved in turn, and then calcined at 600°C and kept for 2 hours. The calcined powder passed 100 Mesh sieve to obtain powder A.

[0046] Get the Ba-Zn-Ti compound of 60 mass parts, the powder material A of 38 mass parts and the SrTiO of 2 mass parts 3 Prepare powder. Put the prepared powder into a ball mill for mixing. The mass ratio of balls, materials, and deionized water in the ball mill is 3:1:3. The grinding balls are zirconia balls. The ball milling time is 4 hours, and the ball mil...

Embodiment 3

[0049] The pure BaCO will first be analyzed 3 , ZnO and TiO 2 The powder is prepared according to the ratio of mass to number of 30:20:50, the prepared powder is ball milled, dried, and sieved in sequence, and then calcined at 1150°C and kept for 2 hours, and the calcined powder is passed through a 100-mesh sieve to obtain Ba -Zn-Ti compound.

[0050] Analytical pure Bi 2 o 3 、H 3 BO 3 and ZnO according to the mass-number ratio of 68:20:12 to prepare powder, the prepared powder was ball milled, dried, and sieved in turn, and then calcined at 600°C and kept for 2 hours, and the calcined powder was passed through a 100-mesh sieve to obtain Powder A;

[0051] Get the Ba-Zn-Ti compound of 55 mass parts, the powder A of 40 mass parts and the SrTiO of 4 mass parts 3 , 0.5 parts by mass of Co 3 o 4 and 0.5 parts by mass of MnCO 3 Prepare powder. Put the prepared powder into a ball mill for mixing. The mass ratio of balls, materials, and deionized water in the ball mill is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com