Phosphorus-nitrogen flame retardant functionalized graphene and preparation method thereof

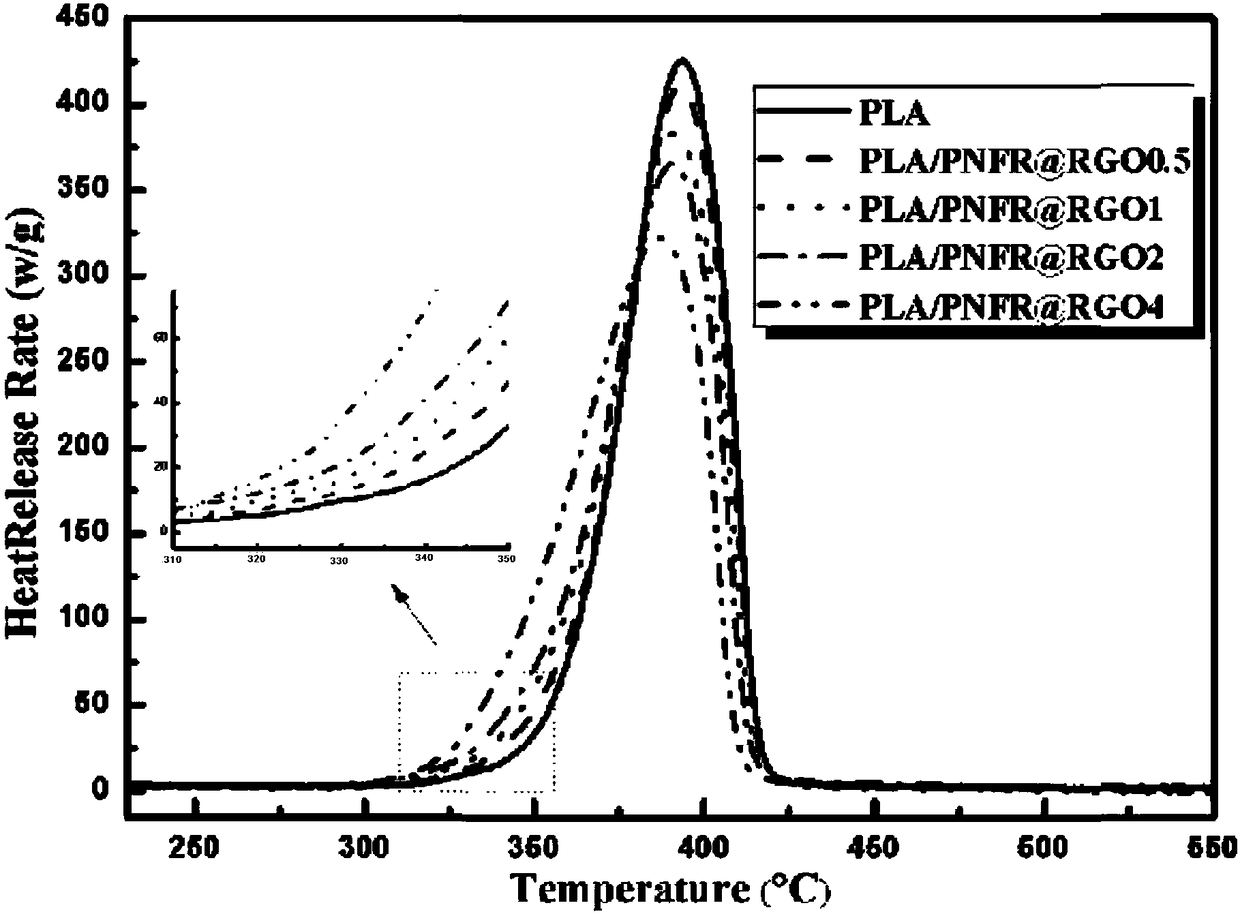

A flame retardant and graphene technology, which is applied in the field of phosphorus-nitrogen flame retardant functionalized graphene and its preparation, can solve the problems of restricting the application of graphene, difficult matrix dispersion, weak matrix force, etc., and achieve good application Foreground, easy to control, high char effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

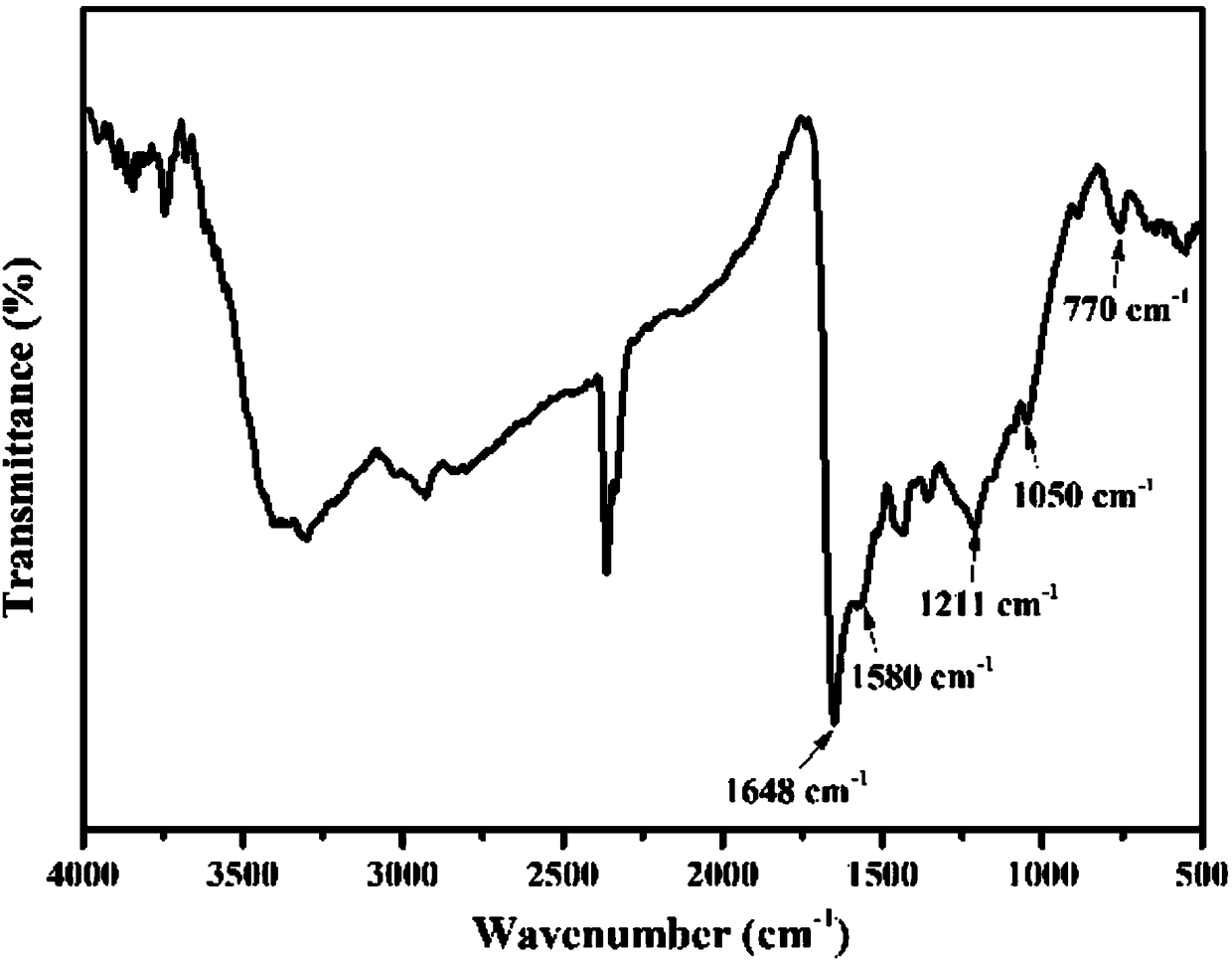

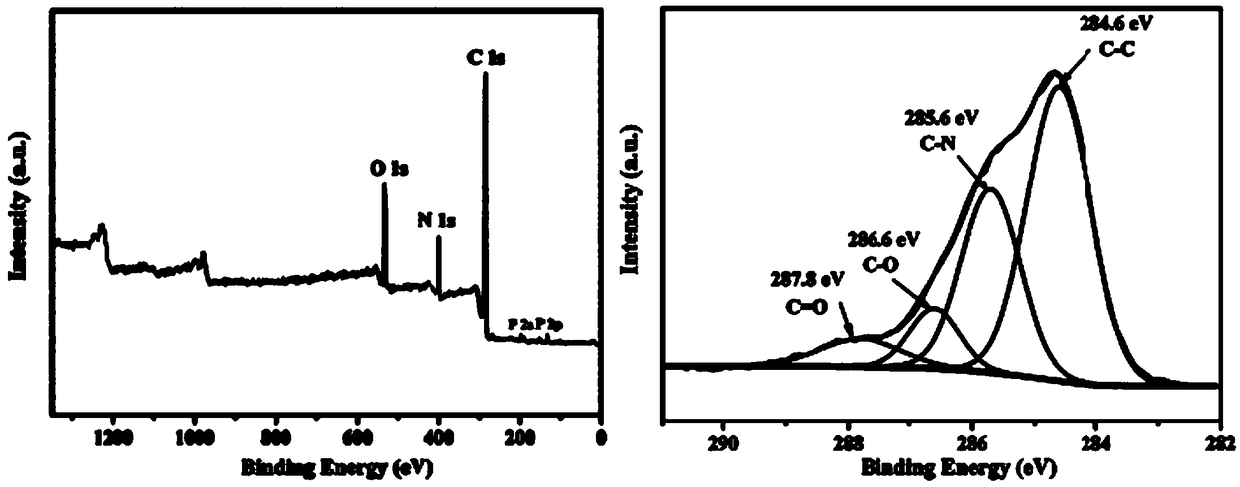

Method used

Image

Examples

Embodiment

[0037] The experimental materials used in this example can be easily obtained from commercial companies unless otherwise specified.

[0038] The first is to prepare graphene oxide (GO) with reference to the Hummers method and a small amount of modification:

[0039] (1) After mixing 5g of graphite and 2.5g of sodium nitrate, add it to 250mL of concentrated sulfuric acid, and then add 15g of potassium permanganate under the condition of mechanical stirring. The above operations were all carried out in an ice-water mixed bath to prevent the reaction from being too violent, and the temperature was controlled below 25°C.

[0040] (2) After removing the ice-water mixed bath, the reaction temperature was raised to 35° C., and then mechanically stirred for 12 h. At this time, the reaction system presents a brown paste.

[0041] (3) After the temperature of the reaction system was lowered to room temperature, it was transferred to an ice-water mixing bath again, and 500 mL of deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com