PBT (polybutylene terephthalate) home decoration film and adhesive tape produced by using film

A home improvement and film technology, which is applied in the field of PBT home improvement film and tapes produced by using the film, can solve the problems of poor flame retardancy and deterioration, and achieve the effects of excellent mechanical properties, easy operation, good flame retardancy and anti-oxidation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

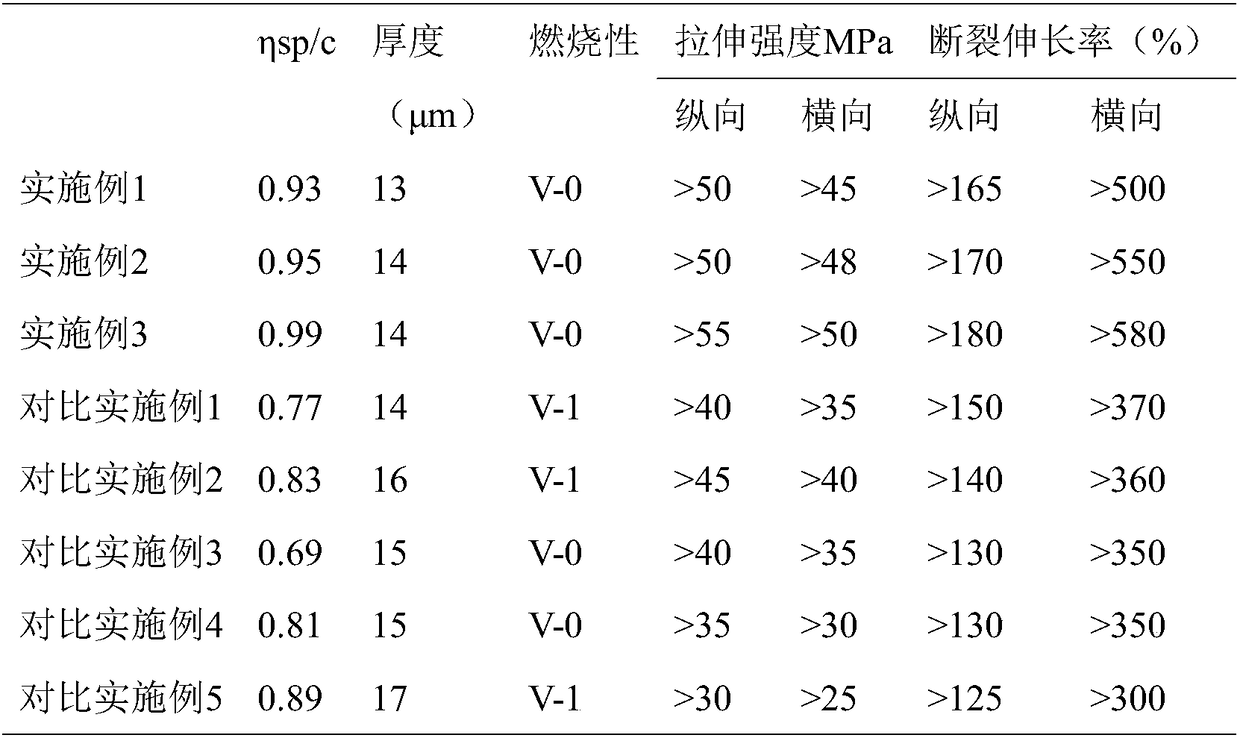

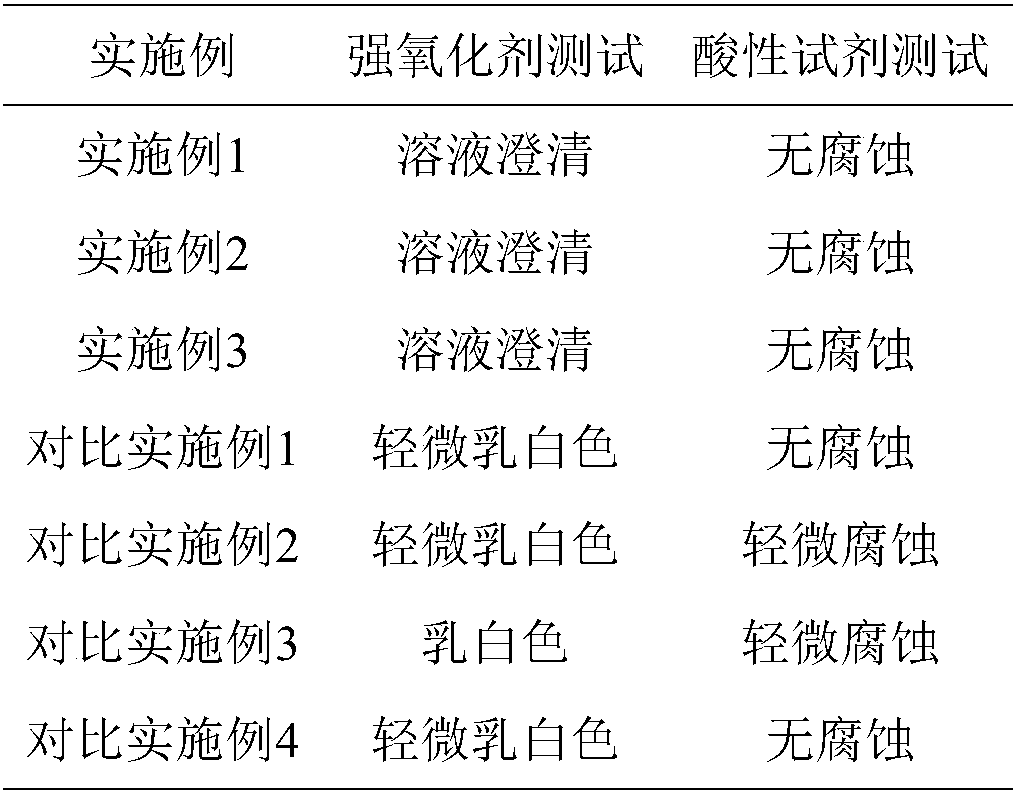

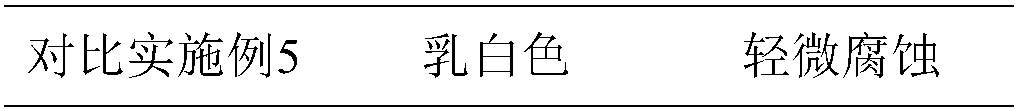

Examples

Embodiment 1

[0047] Embodiment 1: A kind of PBT home decoration film, PBT home decoration film contains the following components by weight

[0048] 5 parts of dibutyl hydroxytoluene, 0.1 part of phthalate diester, 1 part of sodium pyrophosphate, 2 parts of pentaerythritol oleate, 2 parts of polyoxyethylene sorbitan monolaurate, brominated epoxy 15 parts of resin, 10 parts of nano zinc oxide, 5 parts of zinc borate, 35 parts of PBT.

[0049] Preparation Process:

[0050] (1) Put pentaerythritol oleate, phthalic acid diester, sodium pyrophosphate, polyoxyethylene sorbitan-20-polysaccharide monolaurate, PBT and composite flame retardant into a vacuum oven, at 58-63 Dry at a temperature of ℃ to remove moisture;

[0051] (2) PBT and flame retardant of 50% of the prescription amount in step (1) are sent into the extrusion system, melted at 240° C. to obtain molten liquid I, and set aside;

[0052] (3) PBT of step (1) recipe quantity 50% and pentaerythritol oleate, phthalic acid diester, sodiu...

Embodiment 2

[0058] Embodiment 2: A kind of PBT home decoration film, PBT home decoration film contains the following components by weight

[0059] 14 parts of dibutyl hydroxytoluene, 0.5 parts of phthalate diester, 6 parts of sodium pyrophosphate, 5 parts of pentaerythritol oleate, 9 parts of polyoxyethylene sorbitan monolaurate, brominated epoxy 35 parts of resin, 25 parts of nano zinc oxide, 10 parts of zinc borate, 45 parts of PBT.

[0060] The preparation process is the same as in Example 1.

Embodiment 3

[0061] Embodiment 3: A kind of production technology of environment-friendly and energy-saving PBT home decoration film, PBT home decoration film contains the following components by weight

[0062] 10 parts of dibutyl hydroxytoluene, 0.3 parts of phthalic acid diester, 3.5 parts of sodium pyrophosphate, 3.5 parts of pentaerythritol oleate, 5.5 parts of polyoxyethylene sorbitan monolaurate, brominated epoxy 25 parts of resin, 17.5 parts of nano zinc oxide, 7.5 parts of zinc borate, 40 parts of PBT.

[0063] The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com