Water-based curing agent, water-based epoxy resin composition and its application in high-permeability waterproof and reinforced coatings

A water-based epoxy resin and water-based curing agent technology, used in epoxy resin coatings, coatings, etc., can solve the problems of high molecular weight of the curing agent, high shear force, high emulsion viscosity, etc., to achieve high worker acceptance, increase The effect of rebound strength and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

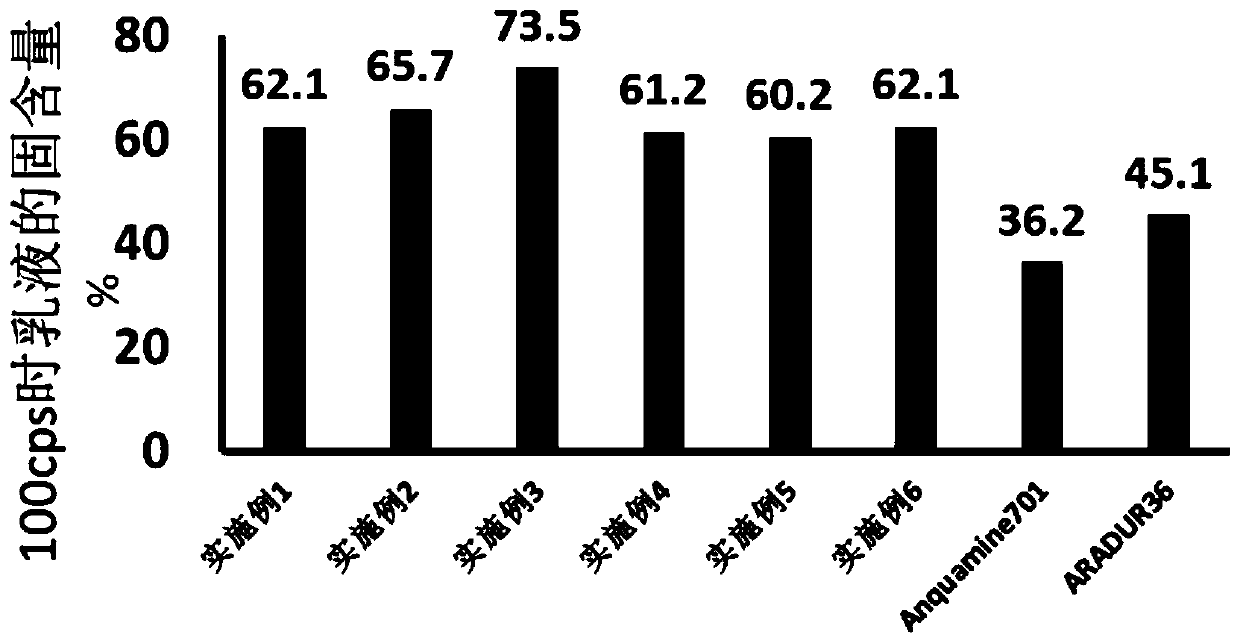

Embodiment 1

[0058] A preparation method of waterborne epoxy resin composition, comprises the following steps:

[0059] Put 100 parts by weight of E51 bisphenol A type epoxy resin and 10 parts by weight of butyl glycidyl ether into a stirring tank, stir evenly, and then discharge and pack to obtain component A;

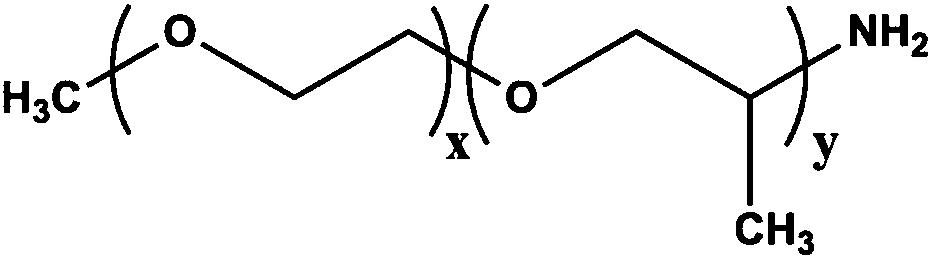

[0060] Preparation of water-based curing agent: mix 1mol phenol and 0.8mol polyetheramine Put it in the reactor and raise the temperature to 45°C; after the phenol and polyetheramine are stirred evenly, add 37% formaldehyde solution in an equimolar amount to polyetheramine M1000 dropwise at a temperature of 45-80°C for 1 hour; dropwise After the addition is complete, keep it warm for 1 hour; then add 0.9 mol of ethylenediamine into the above reactor, stir evenly, and drop 1.1 mol of 37% formaldehyde solution (1.2 times the molar weight of ethylenediamine) at a temperature of 45 to 80°C ), the dropwise addition time was 1.5h; after the dropwise addition, the insulation reaction w...

Embodiment 2

[0064] A preparation method of waterborne epoxy resin composition, comprises the following steps:

[0065] Put 100 parts by weight of E44 bisphenol A type epoxy resin and 20 parts by weight of C12-14 alkyl glycidyl ether into a stirring tank, stir evenly, and then discharge and package to obtain component A.

[0066] Preparation of water-based curing agent: mix 1mol phenol and 0.9mol polyetheramine Put it in the reactor and raise the temperature to 60°C; after the phenol and polyetheramine are stirred evenly, add 37% formaldehyde solution in an equimolar amount to polyetheramine M1000 dropwise at a temperature of 60-80°C for 1 hour; dropwise After the addition is complete, keep warm for 1 hour; then add 0.8 mol of triethylenetetramine into the above-mentioned reactor, and after stirring evenly, add 1 mol of 37% formaldehyde solution dropwise at a temperature of 60-80°C for 1.5 hours; After adding, keep warm for 1 hour; finally add tap water to dilute until the solid content ...

Embodiment 3

[0070] A preparation method of waterborne epoxy resin composition, comprises the following steps:

[0071] Put 100 parts by weight of DER 354 bisphenol F type epoxy resin and 5 parts by weight of benyl glycidyl ether into a stirred tank, stir evenly, and then discharge and pack to obtain component A;

[0072] Preparation of water-based curing agent: mix 1mol phenol and 1mol polyetheramine Put it in the reactor and raise the temperature to 70°C; after the phenol and polyetheramine are stirred evenly, add 37% formaldehyde solution in an equimolar amount to polyetheramine M1000 dropwise at a temperature of 70-80°C for 1 hour; dropwise After the addition is complete, keep it warm for 1 hour; then add 1.1 mol of m-xylylenediamine into the above reactor, stir evenly, then add 1.2 mol of 37% formaldehyde solution dropwise at a temperature of 45-80°C for 1.5 hours After the dropwise addition, keep warm for 1 hour; finally add tap water to dilute until the solid content is 50% and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com