Full-automatic liquid-liquid sample treatment instrument

A sample processing and fully automatic technology, applied in liquid solution solvent extraction, test sample preparation, instruments, etc., can solve the problems of easy pollution of the environment, cumbersome process, difficult automation, etc., to increase the exchange area, avoid pollution, The effect of guaranteeing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

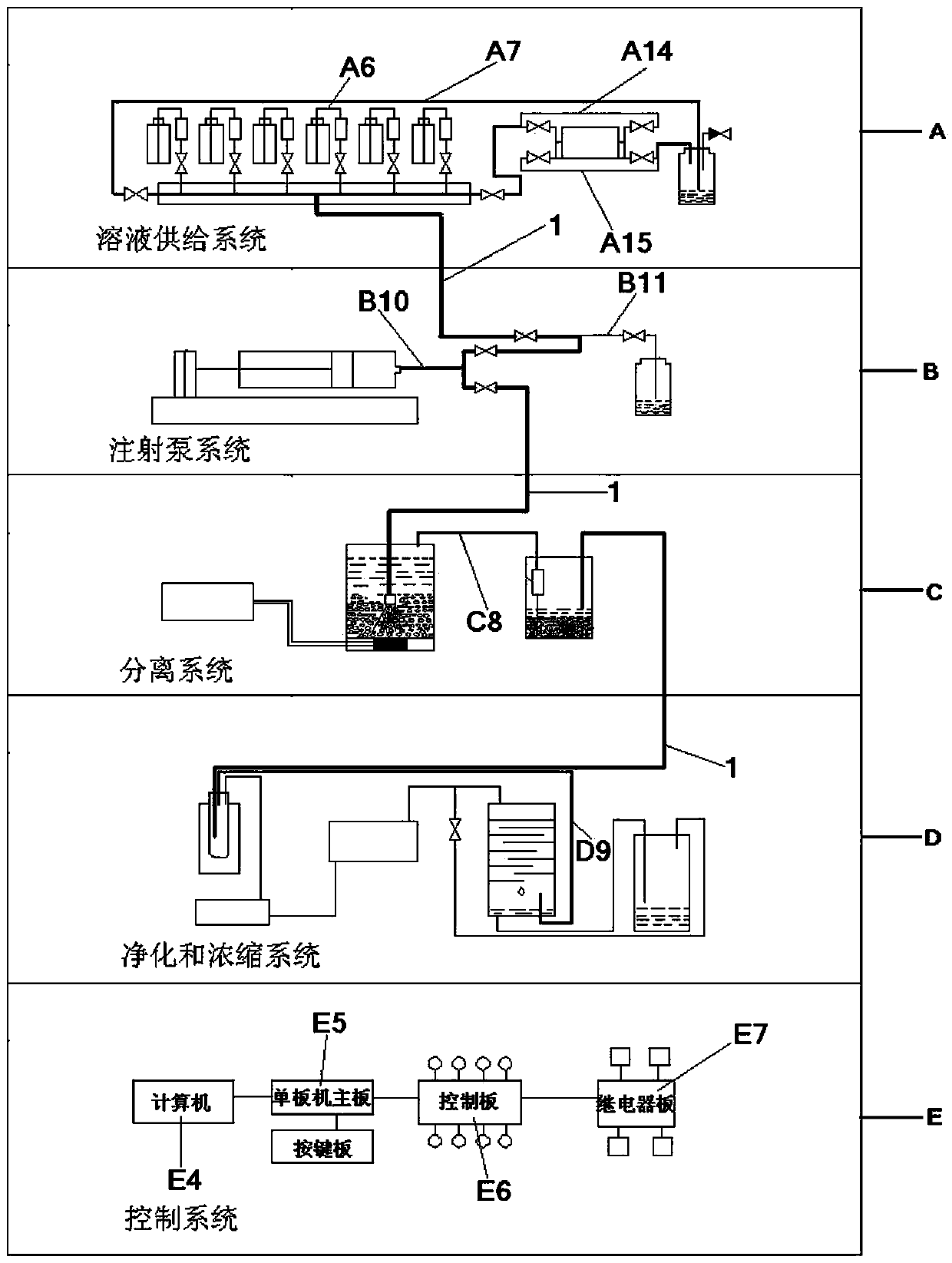

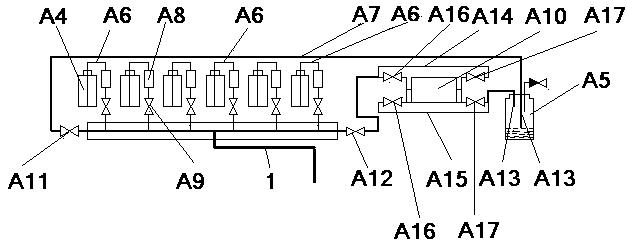

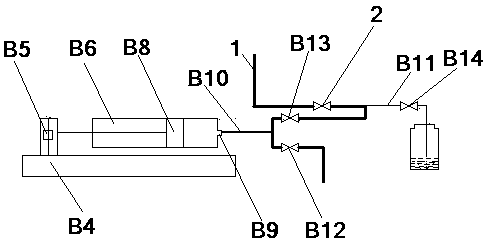

[0045] refer to figure 1 , the present invention includes: a solvent delivery system, a separation system C, a purification and concentration system D, a control system E, the solvent delivery system is composed of a solution supply system A and a syringe pump system B, the solution supply system A, a syringe pump system B. The purification and concentration system D and the separation system C are respectively connected through the main pipeline 1, and the control system E is electrically connected with the solution supply system A, the syringe pump system B, the purification and concentration system D, and the separation system C respectively; The solution supply system A is used for the supply of organic solvents, additives, and cleaning agents used in the extraction process; the syringe pump system B is used for quantitatively extracting the corresponding solvents and injecting them into the extraction container, and controlling the amount of liquid used for extraction, inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com