Volume DBD (dielectric-barrier discharge) based oxide generation and formaldehyde removal device

A technology of dielectric barrier discharge and formaldehyde removal, which is applied in the fields of electrochemical variables of materials, gas treatment, chemical instruments and methods, etc., can solve the problems of high ozone concentration, large water consumption and high device cost, and achieves good removal effect and high detection accuracy. , the effect of uniform discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

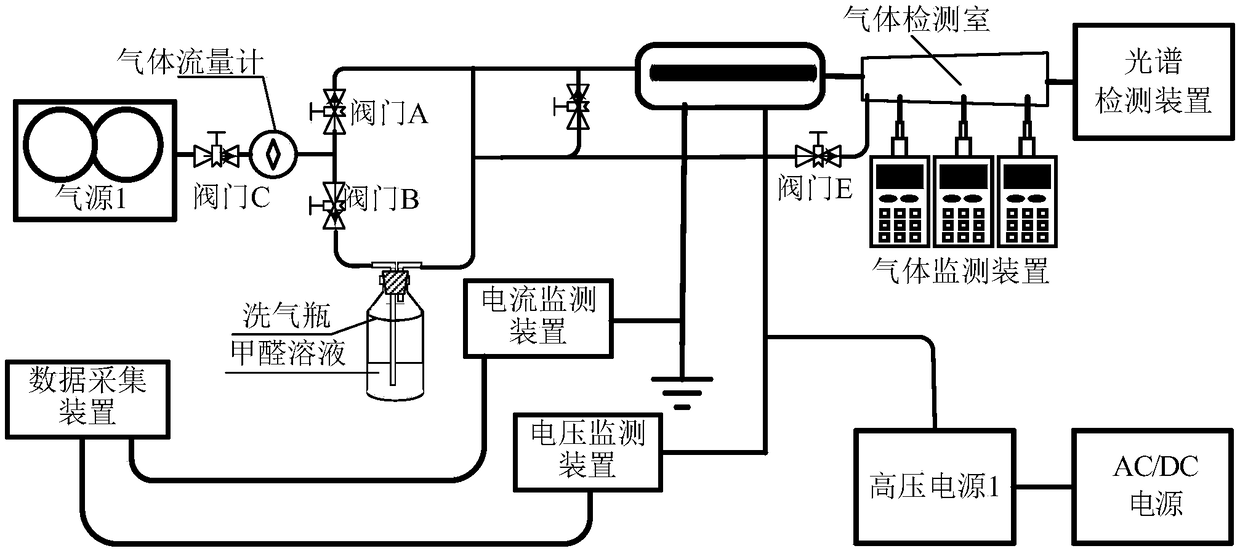

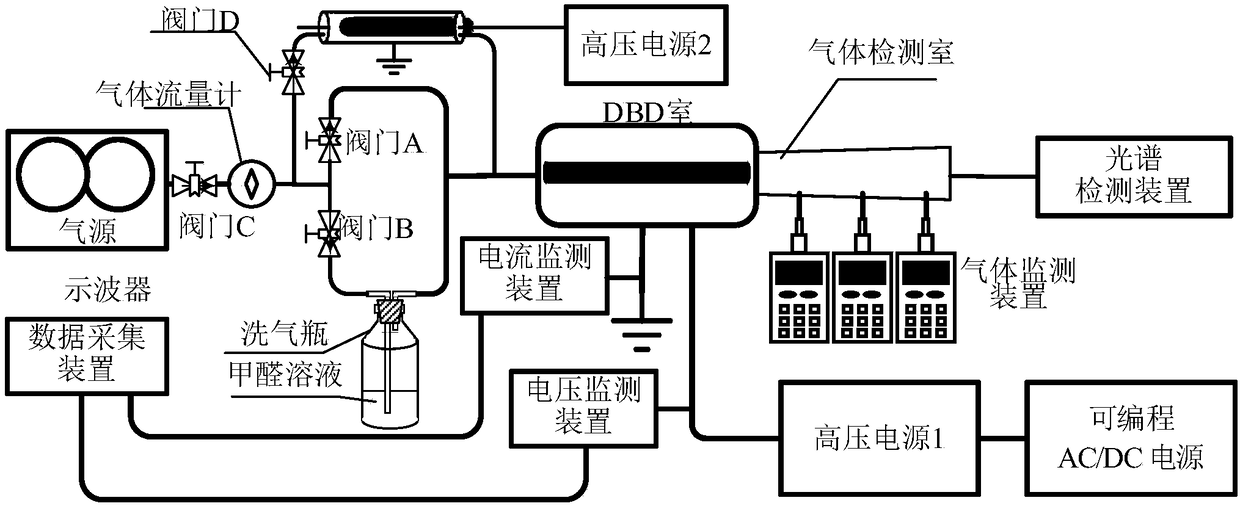

[0060] Example 1 of the experimental device, using the volume dielectric barrier discharge oxide generation and formaldehyde removal device to explore the operation case of removing the main substance of formaldehyde, such as figure 1 As shown, it includes: the gas source for generating the mixed gas of formaldehyde and air, the valve C connected to the gas source, the gas flow meter connected to the gas source, the formaldehyde generator connected between the gas source and the DBD reaction chamber, and the flow rate Valve B to control the concentration of formaldehyde, valve A connected between the gas flow meter and the DBD reaction chamber, the gas detection chamber connected to the DBD chamber, the gas monitoring device connected to the gas detection chamber, and the spectrum detection device connected to the gas detection chamber , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com