Overhead high-voltage line intelligent autonomous flight tour inspection system and method along wires

An intelligent autonomous inspection system technology, applied in the field of inspection, can solve problems such as flight range limitation, failure, and misoperation of equipment, and achieve the effects of accurate images, reduced errors, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

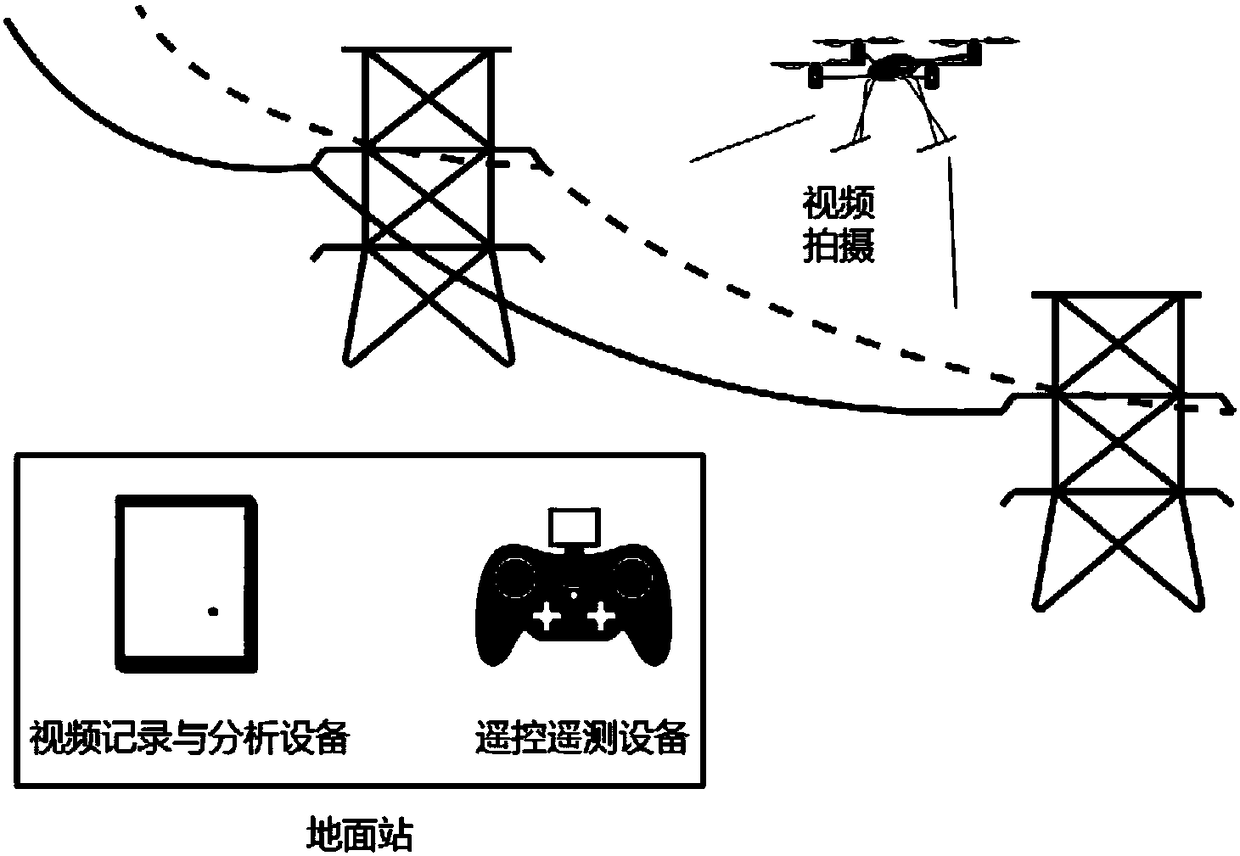

[0048] Such as figure 1 As shown, an intelligent autonomous flight inspection system for overhead high-voltage lines in this embodiment includes a ground station, a lidar data processing module, a multi-rotor drone, and a lidar. Each structure will be described in detail below.

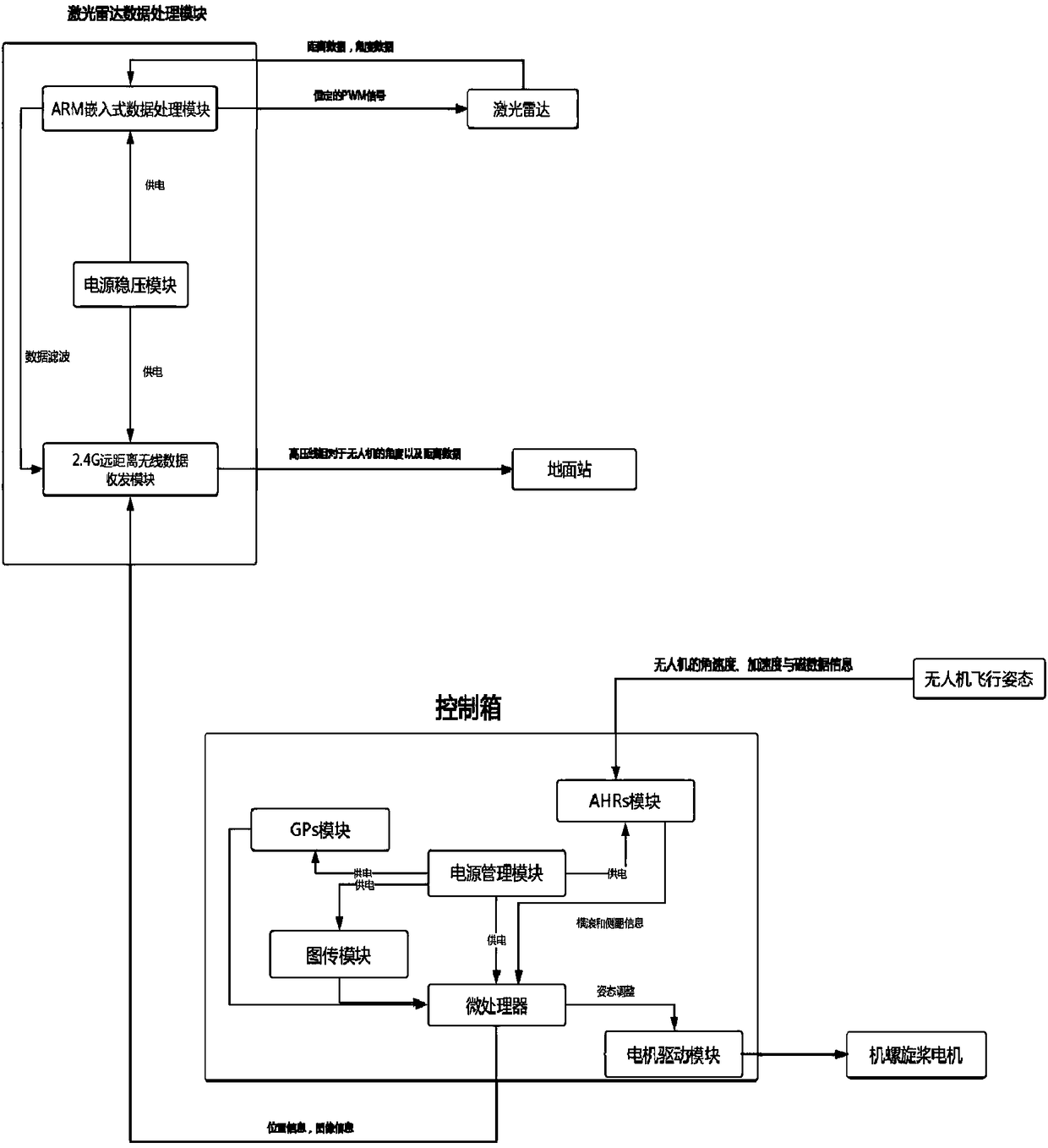

[0049] Such as figure 2 As shown, the laser radar data processing module in this embodiment includes an ARM embedded data processing module, a 2.4G long-distance wireless data transceiver module, and a power supply regulator module. Among them, the ARM embedded data processing module is used to generate a constant PWM to drive the lidar to rotate at a constant speed, and collect the distance data and angle data returned by the lidar, and perform real-time data filtering and data calculation to obtain the relevant high-voltage lines The angle and distance relative to the drone. The power supply voltage regulator module stabilizes the UAV's 16.8V to 24V power supply voltage to 5V for ARM embedded data pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com