Special production line and method for cold pressing extraction of pistacia chinensis seed oil

A Pistacia seed and production line technology, which is applied to presses, manufacturing tools, etc., can solve the problems of affecting the combustion value of biodiesel, unsuitable raw material pressing process, and denaturation of Pistacia seed oil, so as to avoid the denaturation of the extracted oil and facilitate The effect of promotion and implementation and increase of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention. Apparently, the described embodiments are only illustrative partial implementations of the present invention, and are not intended to limit the scope of the present invention. , any equivalent changes and modifications made by those skilled in the art without departing from the concepts and principles of the present invention shall fall within the protection scope of the present invention.

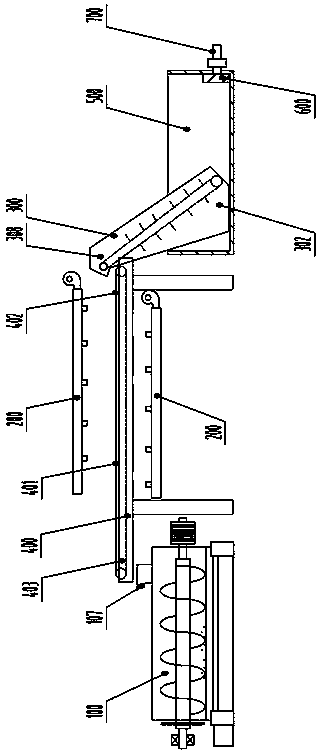

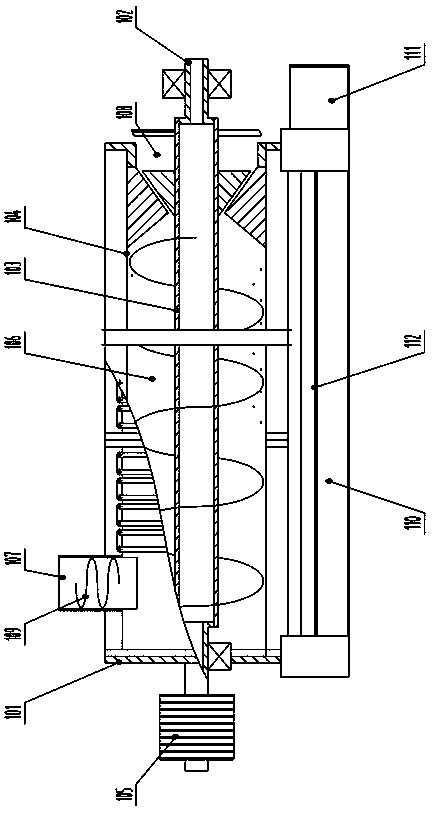

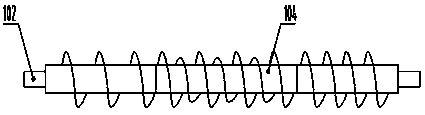

[0043] see figure 1 , in the figure, the special production line for extracting pistachio chinensis oil by cold pressing according to the present invention includes a cleaning tank 500, a lifting conveying device 300, a horizontal conveying device 400, and a screw oil pressing device 100 along the material running direction. Wherein, the lifting conveying device 300 and the horizontal conveying devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com